Rotary drum for improving internal baffle plate structure of drum body in leather production

A baffle structure, drum body technology, applied in leather degreasing, leather/skin/leather/raw hide chemical treatment equipment, small raw hide/large raw hide/leather/fur treatment, etc. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with embodiment:

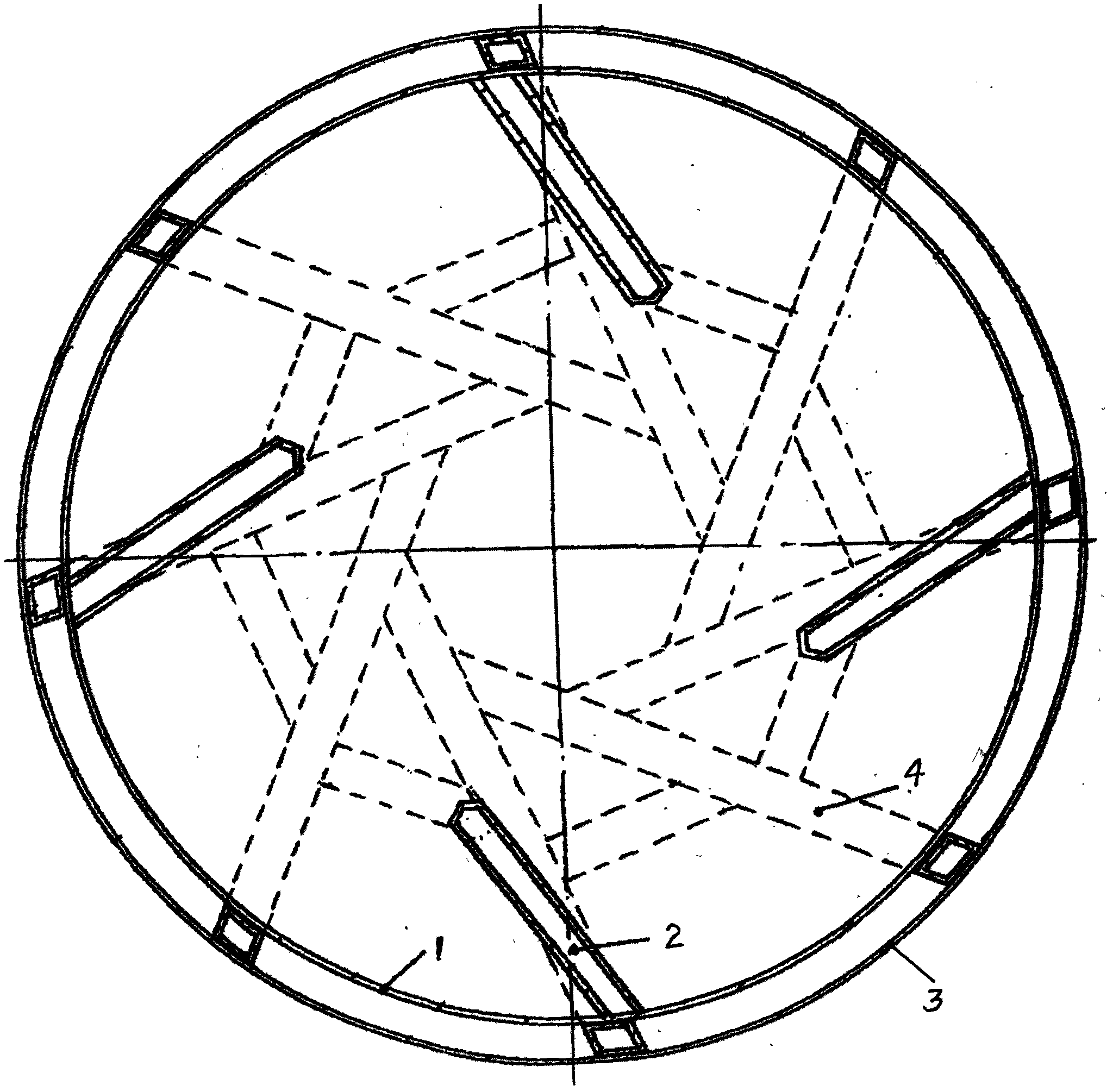

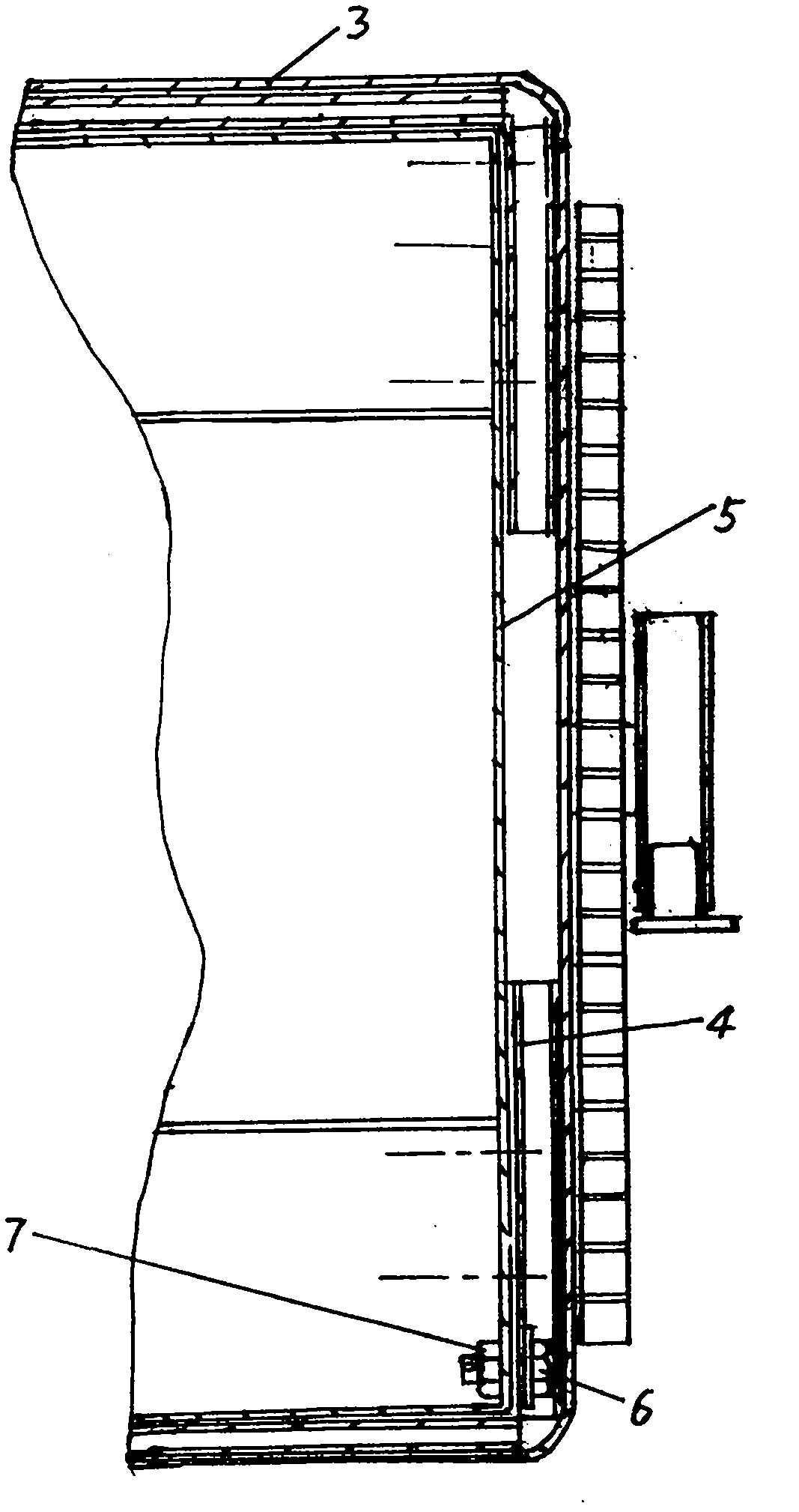

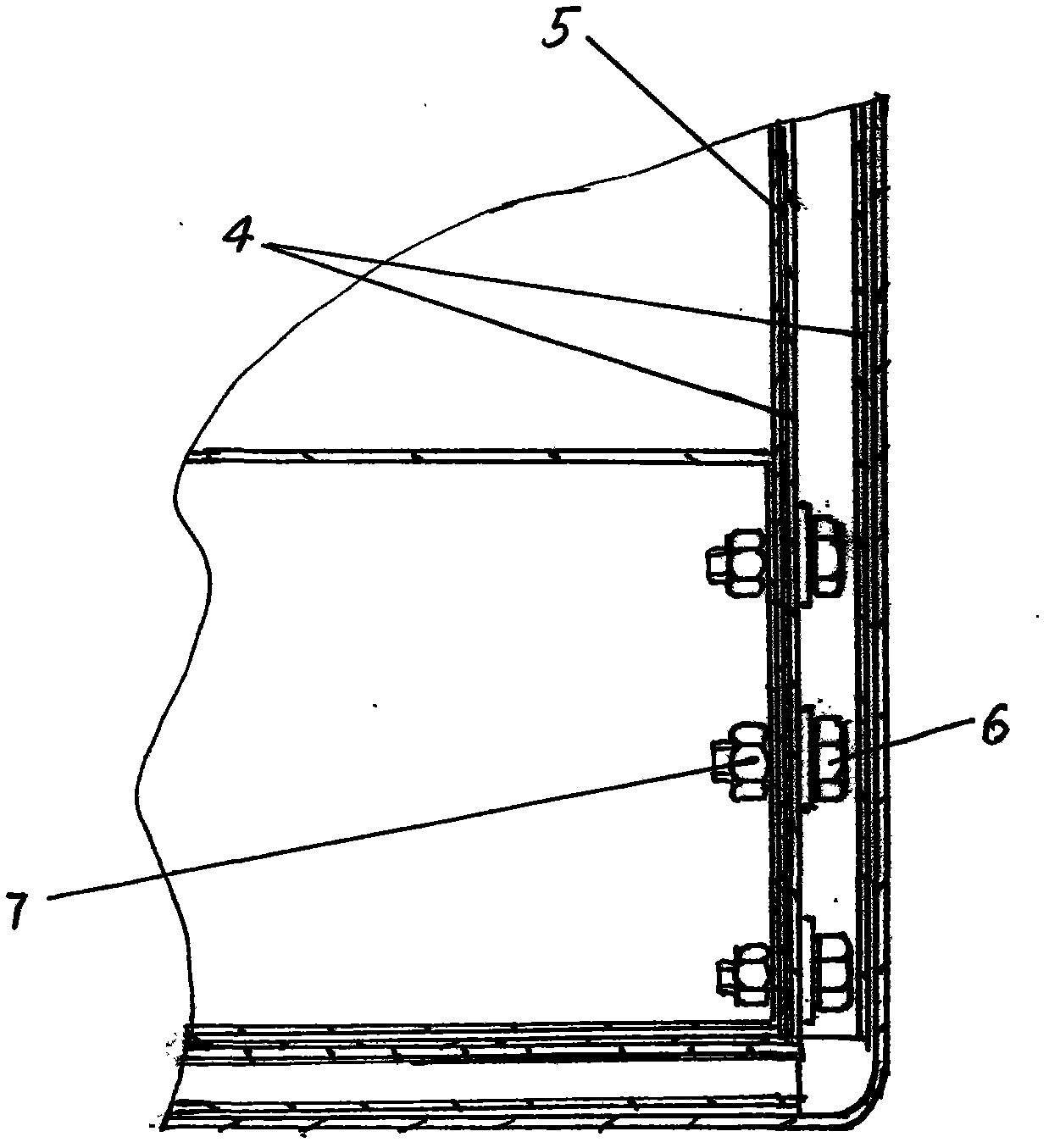

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, the present invention has drum body, and drum body has a cylinder-shaped drum liner, several baffle plates 2 installed in the drum liner the inside. Drum liner has two drum sidewalls 5, a cylindrical drum inwall (or be called drum wall, drum outer wall) 1, and drum liner can be welded by stainless steel plate, also can be made by wooden material. When the drum liner was welded by stainless steel plates, the drum body also had a drum wall shield (skin) 3 that covered the drum liner. The bottom end of each baffle plate 2 is airtightly fixedly connected to the circumferential surface of the drum inner wall 1, and the two side ends of each baffle plate 2 are respectively airtightly fixedly connected to the two drum side walls 5. Each baffle plate The height of 2 is 1 / 5~1 / 3 of the inner circle diameter of dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com