Method for recycling waste gas of butadiene extracting device

An extraction device, butadiene technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc. problems, to achieve the effect of enhancing flow rate, inhibiting deposition, and maintaining catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

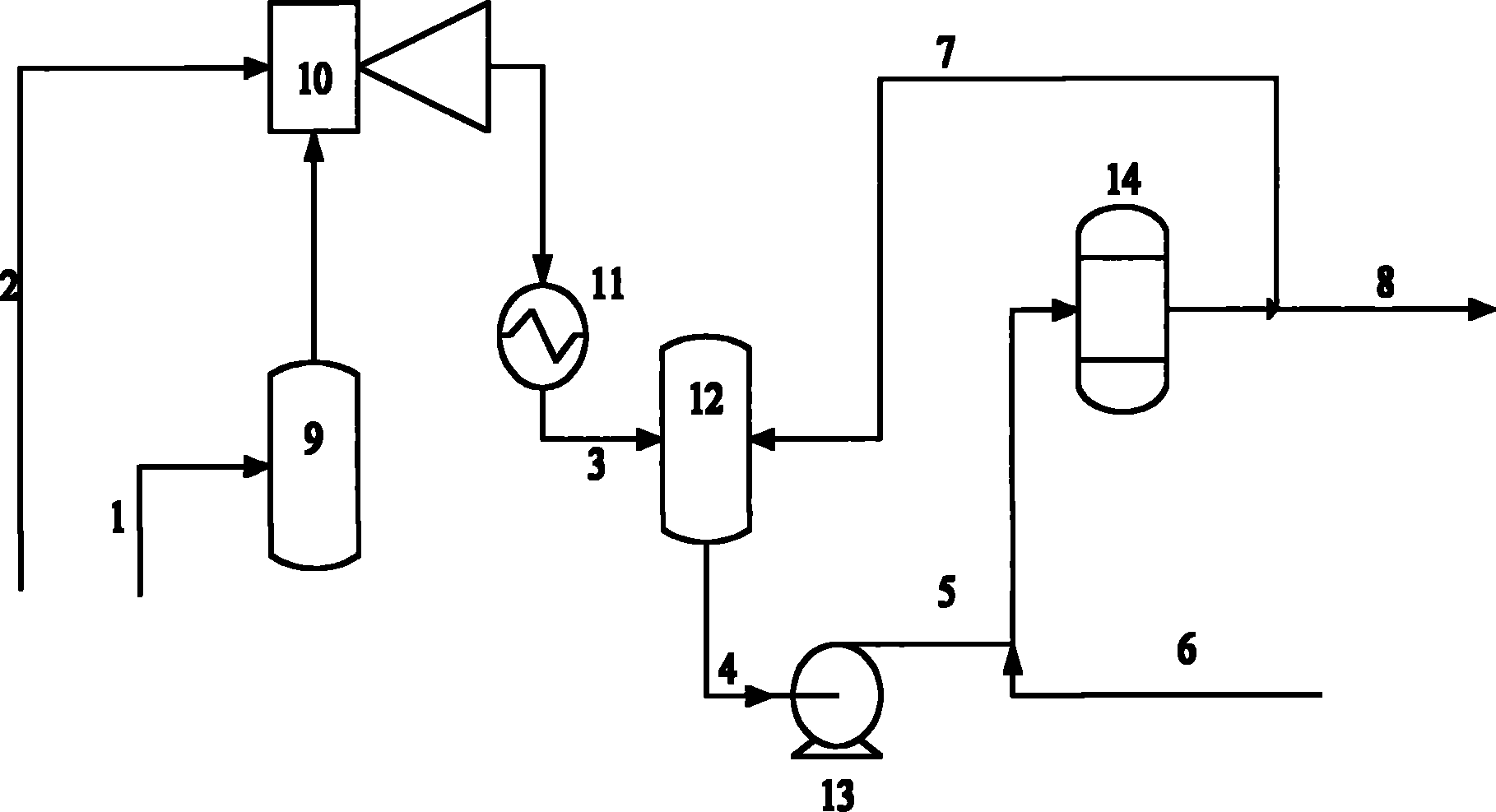

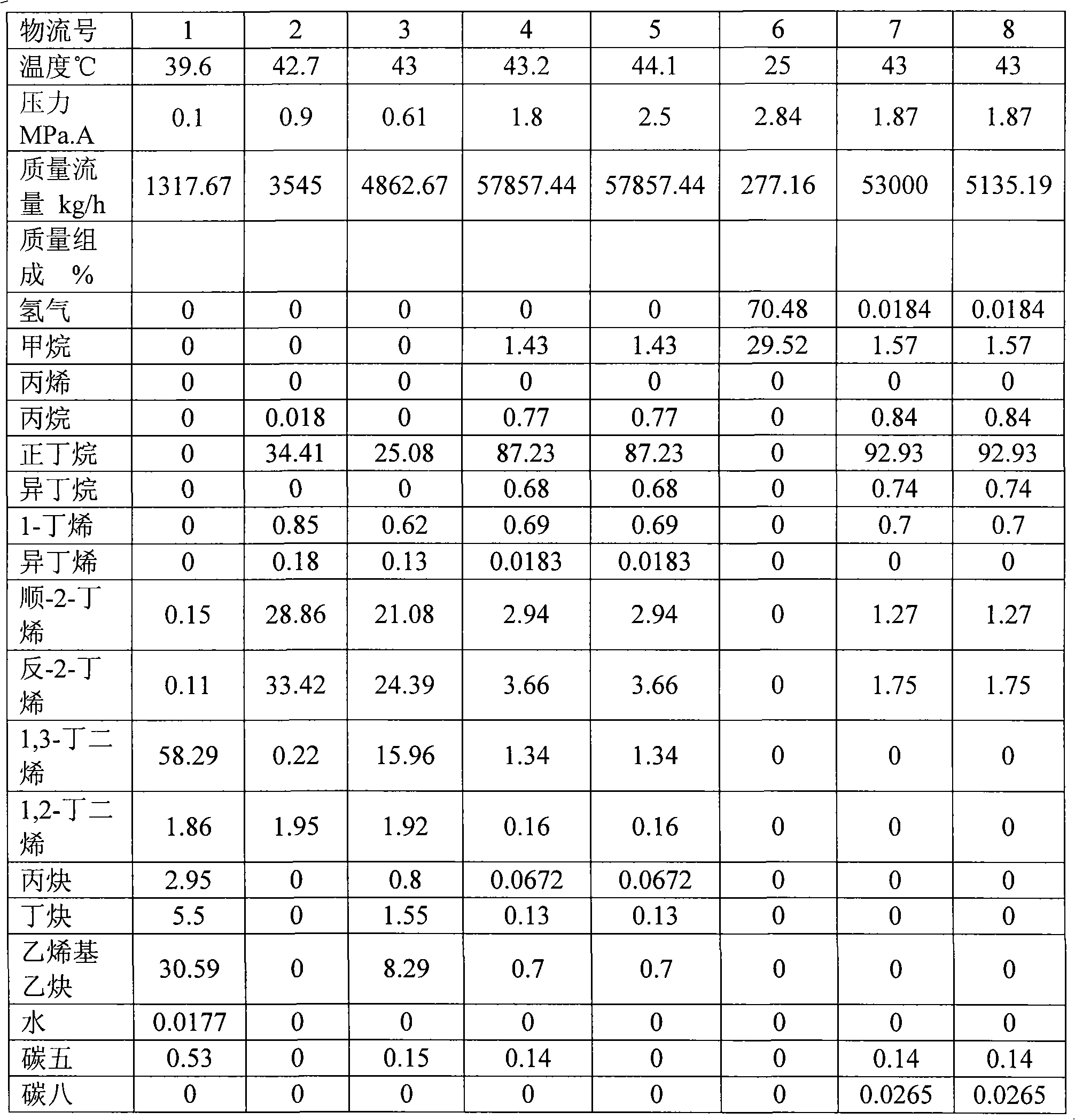

[0048] 1. Boost: Exhaust gas 1 from the butadiene extraction unit (main composition: butene 0.26%, butadiene 60.15%, ethyl acetylene and vinyl acetylene 36.09%, carbon five 0.53%, water 0.02%, both is the mass percent content), the flow rate is 1318kg / h, the pressure is 0.1MPa (absolute pressure), and the waste gas enters the ejector 10 after passing through the buffer tank 9. Liquid phase carbon four 2 (main composition: butane 34.4%, butene 63.3%, butadiene 2.2%) come from the butadiene extraction device, flow rate 3545kg / h, pressure 0.9MPa (absolute pressure), enter injector 10 . After the waste gas 1 is mixed with the liquid-phase C42 through the injector 10, the outlet pressure of the injector is 0.6MPa (absolute pressure), the temperature is 58°C, and after cooling to 43°C, it becomes the liquid-phase mixed C43, in which the alkyne content is 10.6%;

[0049] 2. Reaction: After dehydration, the mixed C43 enters the mixing tank 12 and mixes with the circulating alkane 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com