Integral treatment process of oily sewage of oil field

A treatment process and technology for oily sewage, which is applied in flotation water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problems of difficult discharge standards, complex water quality of oily sewage in oil fields, etc., and achieve decolorization effect Good, substantive features Continuous degreasing, small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Example: Treatment of fracturing wastewater in an oil field, raw water indicators: COD 2000-4000mg / L, suspended solids 200-300mg / L, oil content 200-250mg / L, turbidity 200-370NTU, pH 7 -9.

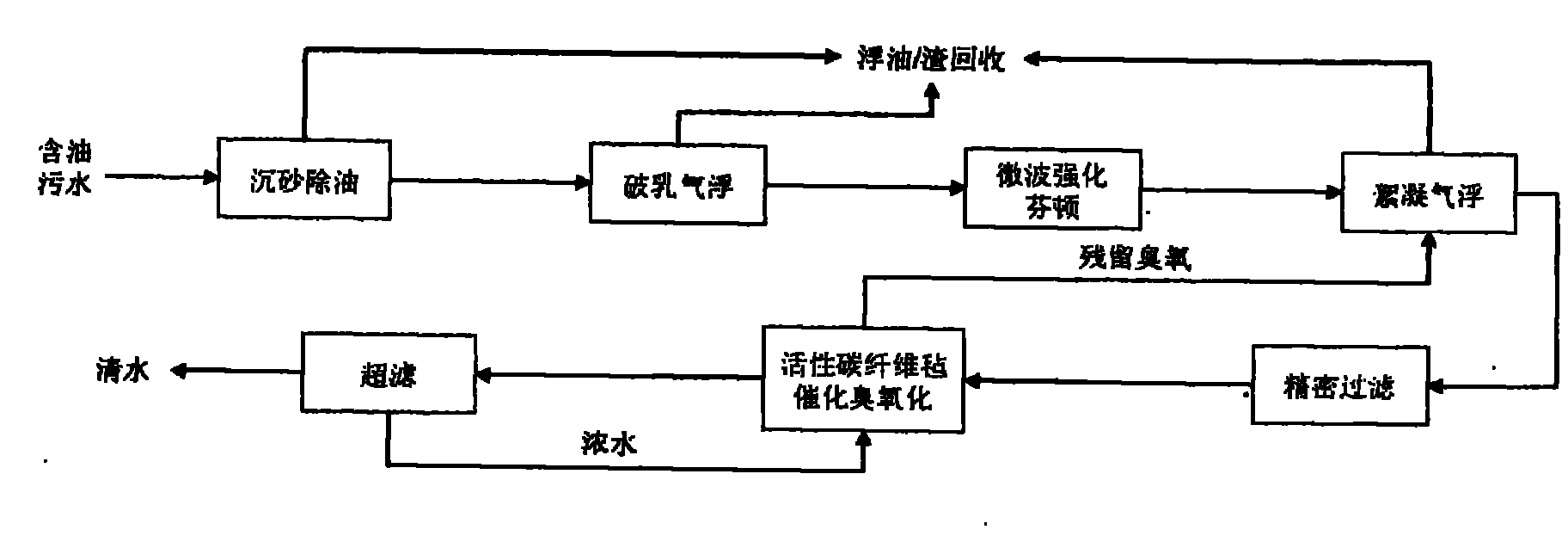

[0022] It can be seen from the accompanying drawings that the present invention is an integrated treatment process for oily sewage in oilfields. The process flow is: oily sewage in oilfields - grit degreasing - demulsification air flotation - microwave enhanced Fenton - flocculation air flotation - precision filtration - activated carbon fiber felt Catalytic ozonation-ultrafiltration-clean water, the specific treatment process of each treatment unit in the above process is as follows:

[0023] (1) In the pretreatment of grit settling and degreasing in the integrated process, the principle of gravitational degreasing is used to carry out conventional oil separation and desanding treatment. The oil device is made of carbon steel, with anti-corrosion treatment inside, the residence tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com