Moxibustion patch and preparation method thereof

A patch and one-sided technology, which is applied in the direction of pharmaceutical formulations, other medical devices, and medical preparations containing active ingredients, can solve problems such as polluting clothes, achieve the effects of restoring health and vitality, avoiding volatilization loss, and accurate quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In parts by weight, weigh 15 parts of fumed silica and 3 parts of mugwort leaf oil, mix well, add 81 parts of polyacrylate emulsion with a mass concentration (g / L) of 40%, and then add 0.01 part of antioxidant vitamin E , fully disperse and mix, then add 1 part of FS-20C viscosity modifier produced by Dandong Star Fine Chemical Co., Ltd. to thicken until the viscosity of the material liquid is 100,000 centipoise, and obtain a thick slurry;

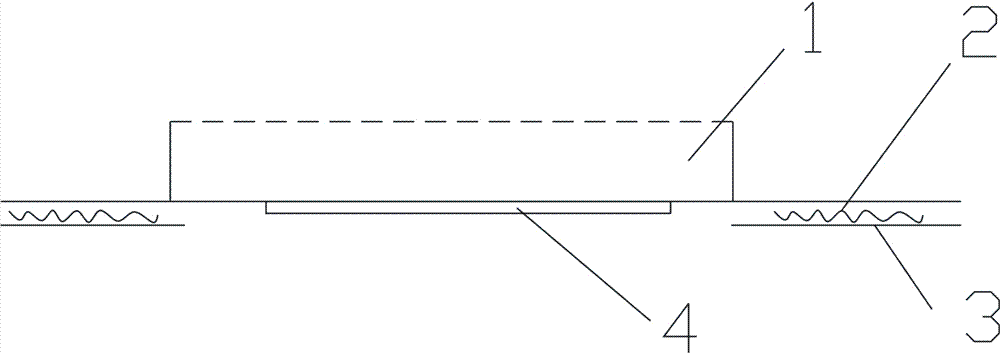

[0027] Coat the above thick slurry on one side of the non-woven fabric base material, the coating amount is about 160g / m2, and bake it with hot air at about 60°C until it is solidified and shaped into a film to obtain an essential oil sustained-release film, and then on the non-woven fabric The other side of the cloth substrate is coated with hot-melt pressure-sensitive adhesive, then covered with release paper, and die-cut into slices to obtain essential oil slow-release membranes;

[0028] Remove the release paper from the essenti...

Embodiment 2

[0031] In parts by weight, weigh 6.0 parts of polyvinyl alcohol, 70 parts of water and 1 part of glycerin, mix them, heat to 100°C to dissolve to obtain a mixed solution of polyvinyl alcohol, add 19 parts of kaolin, 1 part of titanium dioxide, and 1 part of cinnamon oil. 1 part of pre-prepared powder is fully dispersed evenly, then add 0.1 part of antioxidant di-tert-butyl hydroxytoluene and 2 parts of propylene glycol alginate viscosity modifier to adjust the viscosity of the feed liquid to 100,000 centipoise to obtain a thick slurry ;

[0032] Coat the above thick slurry on one side of the non-woven fabric base material, the coating amount is about 200g / m2, dry part of the water with hot air at about 60°C until it solidifies and forms a film to obtain the essential oil slow-release film, and then Coat the other side of the substrate with hot-melt pressure-sensitive adhesive, then cover the release paper, die-cut into slices, and obtain the essential oil slow-release film;

...

Embodiment 3

[0035] In parts by weight, weigh 4 parts of sodium polyacrylate, 85 parts of water, 0.6 parts of aluminum hydroxide and 5 parts of glycerin, dissolve to obtain a mixed solution of sodium polyacrylate, add 10 parts of light calcium carbonate, 1 part of titanium dioxide, 2 parts of juniper oil and 0.3 parts of antioxidant butyl hydroxyanisole pre-prepared powder, fully dispersed evenly, that is, a thick slurry with a viscosity of 100,000 centipoise is obtained;

[0036] Coat the above thick slurry on the non-woven fabric base material, the coating amount is about 200g / m2, dry part of the water under the condition of about 60 ℃ with hot air until solidified and shaped into a film, to obtain the essential oil slow-release film, and then in the absence of The other side of the woven fabric substrate is coated with hot-melt pressure-sensitive adhesive, then covered with release paper, and die-cut into slices to obtain essential oil slow-release membranes;

[0037] Remove the release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com