Artificial surface-active substance mixed liquid as well as preparation and application thereof

A technology of active substances and artificial surfaces, applied in the direction of drug combinations, peptide/protein ingredients, medical preparations of non-active ingredients, etc., can solve problems such as weak effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

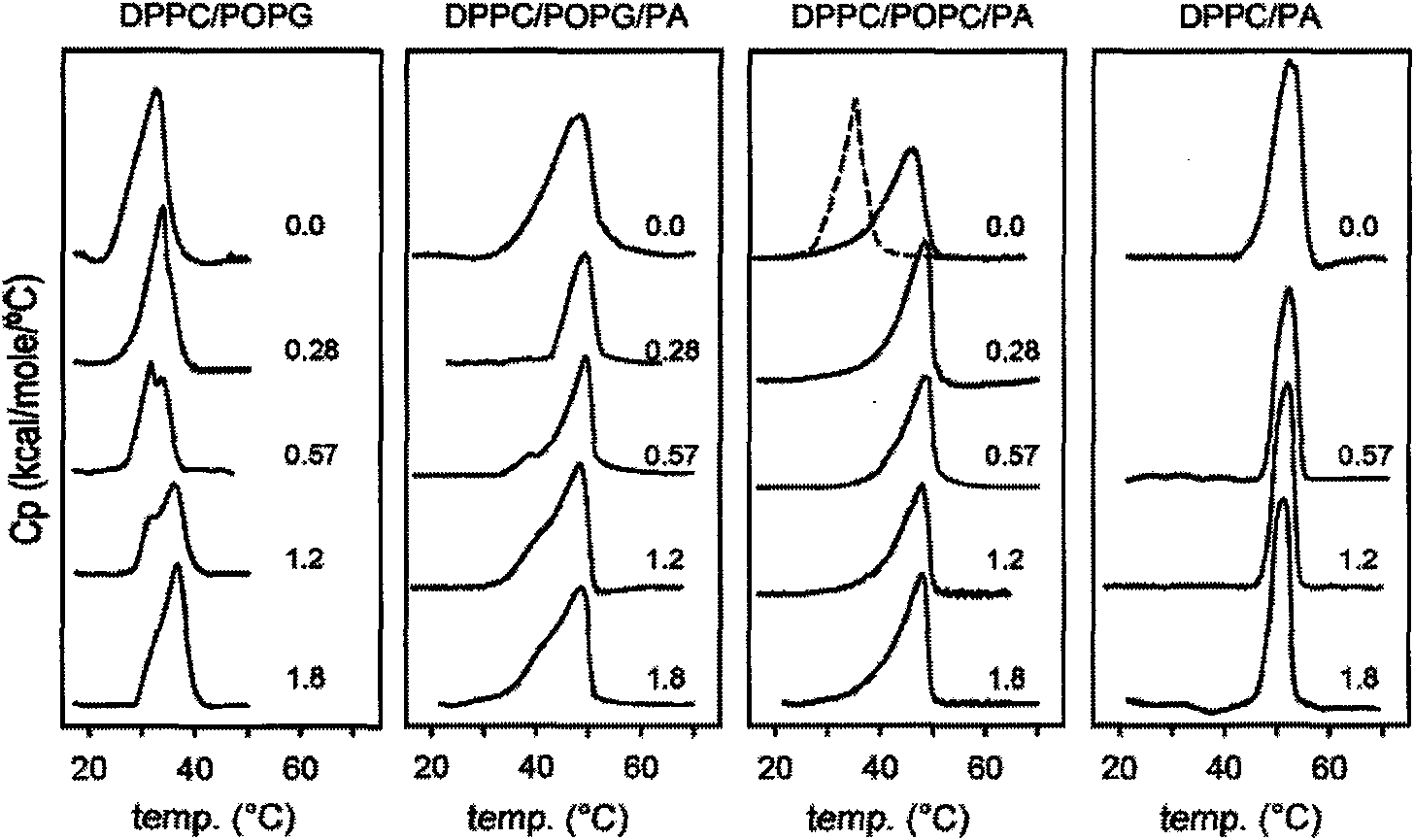

[0024] Embodiment 1 The mixed solution of pulmonary surfactant and its preparation

[0025] Recipe: DPPC 23g

[0026] POPG 8g

[0027] Oleic acid 4g

[0028] SP-B 1g

[0029] Phosphate buffer to 100g

[0030] Preparation: Make a solvent with the ratio of chloroform:methanol=2:1 (v / v); dissolve DPPC and POPG in the solvent according to the above ratio, mix well, quickly evaporate to remove the organic solvent, and freeze-dry at low temperature to obtain powdered phospholipid; Add 1% SP-B and oleic acid to phosphate buffer solution, add mixed freeze-dried DPPC and POPG components, stir in a warm bath at 40°C until completely dissolved, and make the final concentration reach SP-B1-2%, DPPC 20-30 %, POPG5-15%, for distribution.

Embodiment 2

[0031] Embodiment 2 The mixed solution of pulmonary surfactant and its preparation

[0032] Recipe: DPPC 23g

[0033] POPG 8g

[0034] Oleic acid 4g

[0035] SP-B 0.5g

[0036] SP-C 0.5g

[0037] Phosphate buffer to 100g

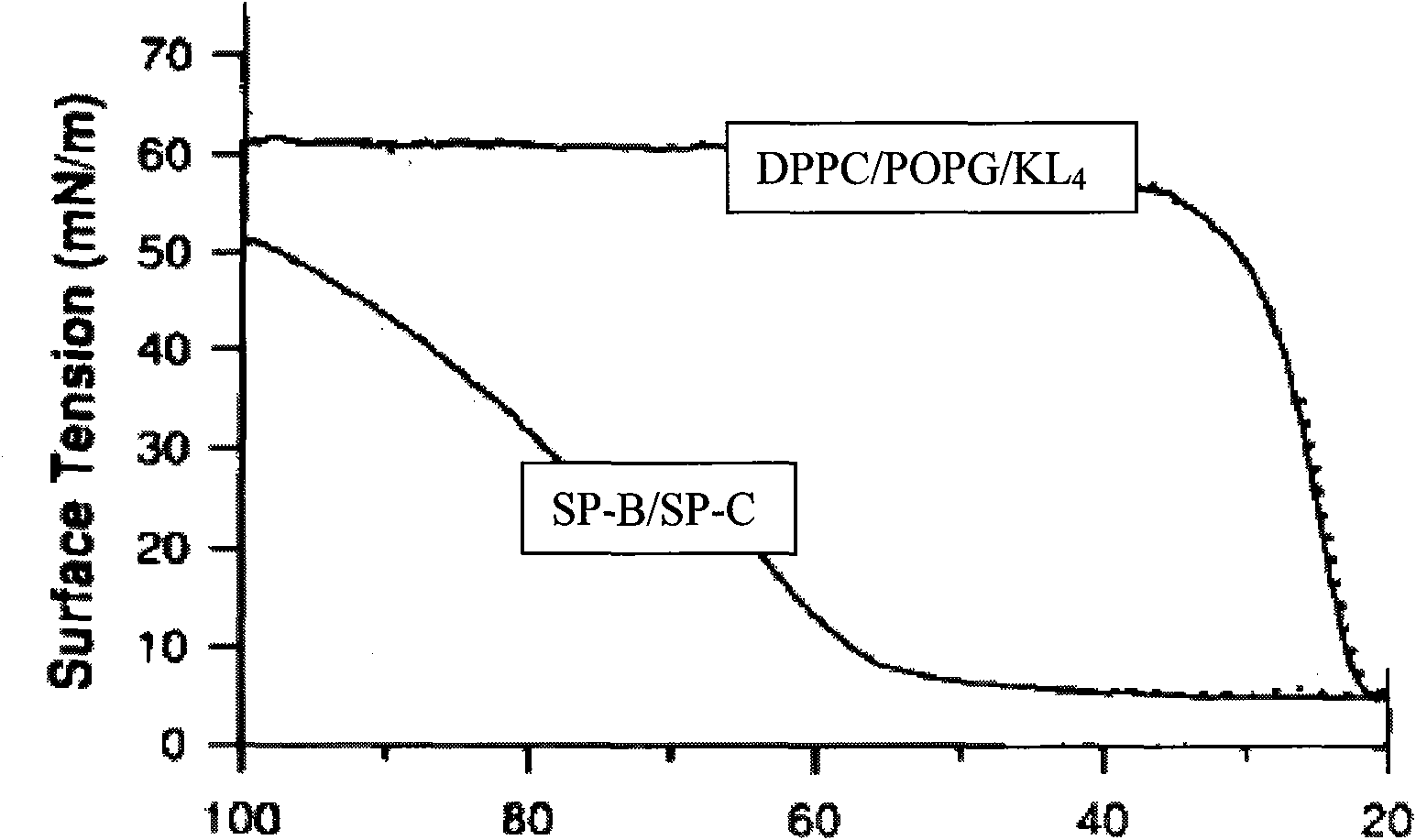

[0038] Preparation: Make a solvent with the ratio of chloroform:methanol=2:1 (v / v); dissolve DPPC, POPG, and oleic acid into the solvent according to the above ratio, mix well, quickly evaporate to remove the organic solvent, and freeze-dry at low temperature to obtain powder Phospholipids; add 0.5% SP-B and 0.5% SP-C to phosphate buffer, add mixed freeze-dried DPPC and POPG components, stir in a 40°C warm bath until completely dissolved, and make the final concentration reach SP-B0. 5-1%, SP-C0.5-1%, DPPC 20-30%, POPG5-15%, for separate equipment.

Embodiment 3

[0039] Embodiment 3 The mixed solution of pulmonary surfactant and its preparation

[0040]Recipe: DPPC 23g

[0041] POPG 8g

[0042] Oleic acid 5g

[0043] KL 4 1g

[0044] Tris Buffer Add to 100g

[0045] Preparation: Make a solvent with the ratio of chloroform:methanol=2:1 (v / v); dissolve DPPC, POPG, and oleic acid into the solvent according to the above ratio, mix well, quickly evaporate to remove the organic solvent, and freeze-dry at low temperature to obtain powder Phospholipids; Phosphate buffered saline with 1% KL 4 , add the mixed freeze-dried DPPC and POPG components, stir in a 40°C warm bath until completely dissolved, and make the final concentration reach KL 4 1-2%, DPPC 20-30%, POPG5-15%, for separate equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com