Preparation method of PbO2 electrode with high oxygen evolution potential and long service life

A technology with oxygen evolution potential and long life, applied in the field of material chemistry, it can solve the problems affecting the electrochemical activity and stability of electrodes, weak binding force, large resistance, etc., and achieve good electrocatalytic performance, increase assembly capacity, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

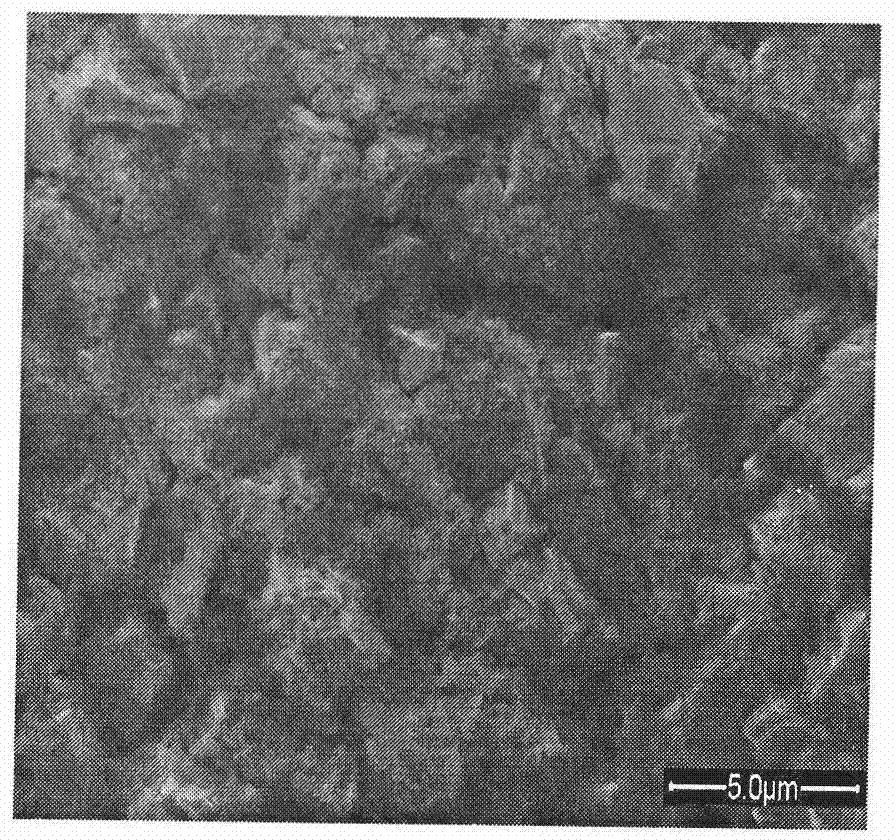

[0026] F-PbO 2 / Ti electrode preparation. Described method specifically comprises the following steps:

[0027] (1) Set the thickness to 0.08mm and the size to 3cm 2The surface of the pure titanium sheet is mechanically polished and cleaned;

[0028] (2) 0.4mol / L Pb(NO 3 ) 2 , 0.03mol / L NaF, 0.08mol / L HNO 3 , 6ml / L fluororesin is prepared as electroplating solution;

[0029] (3) With the Ti prepared in step (1) as the working electrode, the platinum sheet as the auxiliary electrode, and the saturated calomel electrode (SCE) as the reference electrode, at a reaction temperature of 80°C, the fluorine-containing PbO 2 Deposited on a Ti plate, the deposition current is 0.04A / cm 2 , the deposition time is 1h, the preparation of F-PbO 2 / Ti electrode electrode products.

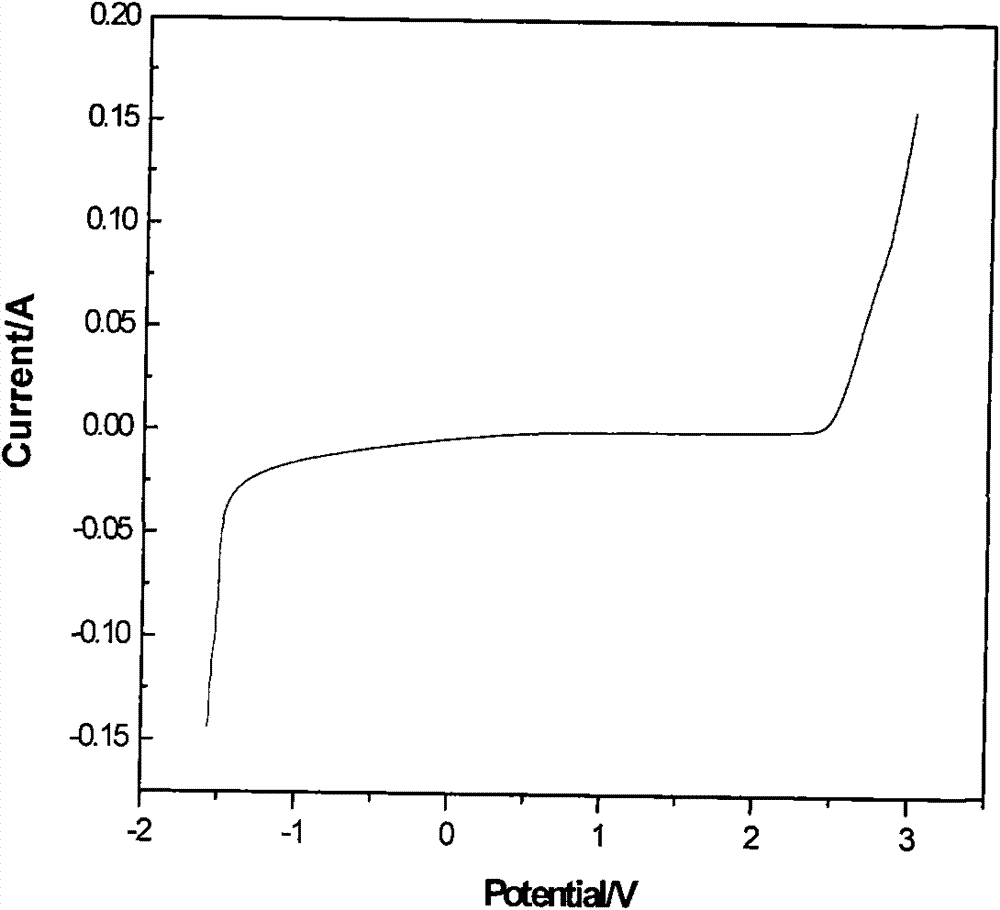

[0030] (4) The oxygen evolution potential of the electrode is about 1.9V, and the service life of the electrode is about 3 years calculated from the accelerated life test results.

Embodiment 2

[0032] PbO 2 / TiO 2 - Preparation of NTs / Ti electrodes. Described method specifically comprises the following steps:

[0033] (1) Set the thickness to 0.08mm and the size to 3cm 2 The surface of the pure titanium sheet is mechanically polished and cleaned;

[0034] (2) With 0.05wt% NaF and supporting electrolyte 1.6wt% Na 2 SO 4 As solute, add alcohol additive 10wt% polyethylene glycol (PG400), the solvent is water balance, prepare electrolyte;

[0035] (3) With the titanium sheet in step (1) as the working electrode, the platinum sheet as the counter electrode, and the distance between the working electrode and the counter electrode is 0.5cm, carry out electrochemical anodizing treatment, the anodizing voltage is 10V, and the anodizing time is 3h , to obtain upright ordered TiO on the Ti-based surface 2 nanotube arrays;

[0036] (4) 0.4mol / L Pb(NO 3 ) 2 , 0.03mol / L NaF, 0.08mol / L HNO 3 , 10ml / L of fluororesin is prepared as electroplating solution;

[0037] (5) Ti...

Embodiment 3

[0040] A kind of PbO with high oxygen evolution potential 2 Electrode and preparation method, the method is to adopt the electrochemical deposition method, with titanium dioxide nanotubes grown upright on the titanium base as the carrier, to prepare F-PbO 2 / TiO 2 - NTs / Ti electrodes. Described method specifically comprises the following steps:

[0041] (1) Set the thickness to 0.1mm and the size to 6cm 2 The surface of the pure titanium sheet is mechanically polished and cleaned;

[0042] (2) with 1.0wt% NaF and supporting electrolyte 2.0wt% Na 2 SO 4 As solute, add alcohol additive 50wt% polyethylene glycol (PG400), the solvent is the water balance, prepare electrolyte;

[0043] (3) With the titanium sheet in step (1) as the working electrode, the platinum sheet as the counter electrode, the distance between the working electrode and the counter electrode is 1.0 cm, carry out electrochemical anodizing treatment, the anodizing voltage is 20V, and the anodizing time is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com