Preparation device for refrigeration water energy-saving for production

A preparation device and cold water technology, applied in the field of machinery, can solve the problems of high proportion of refrigerating parts, long start-up time of refrigerating machines, ignoring energy saving, etc., and achieve saving of refrigerating expenses, energy-saving equipment consumption, structural technology mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

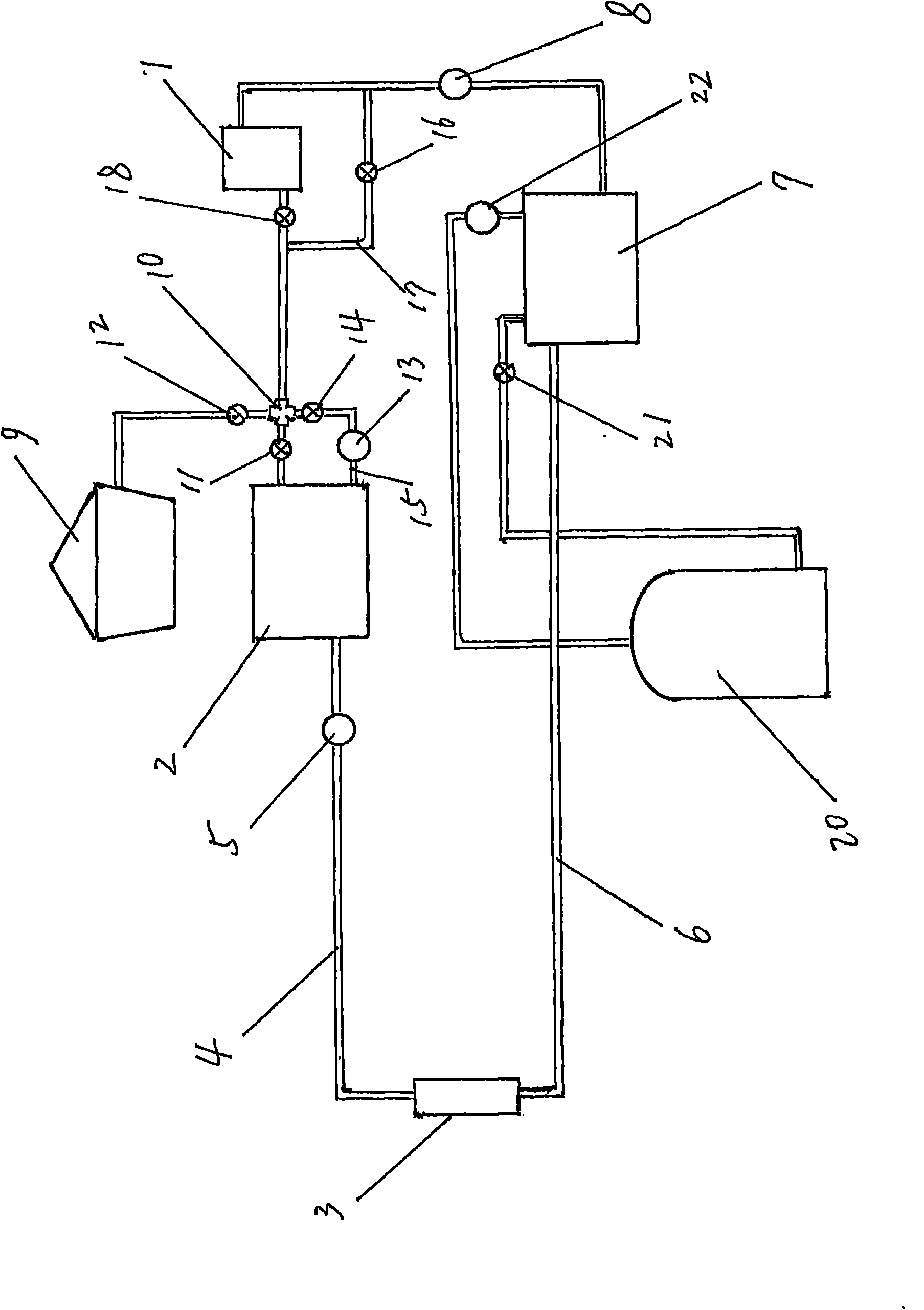

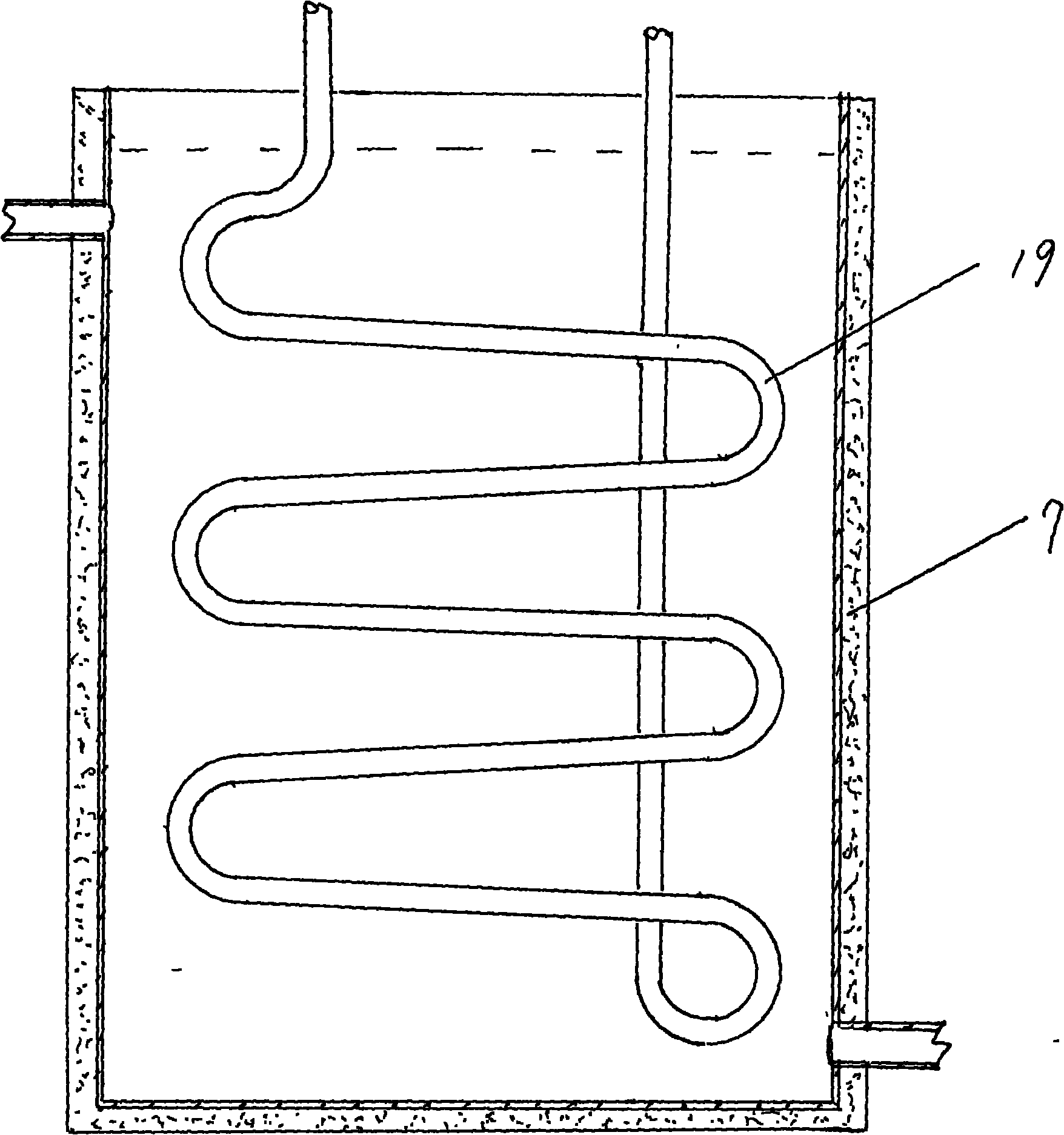

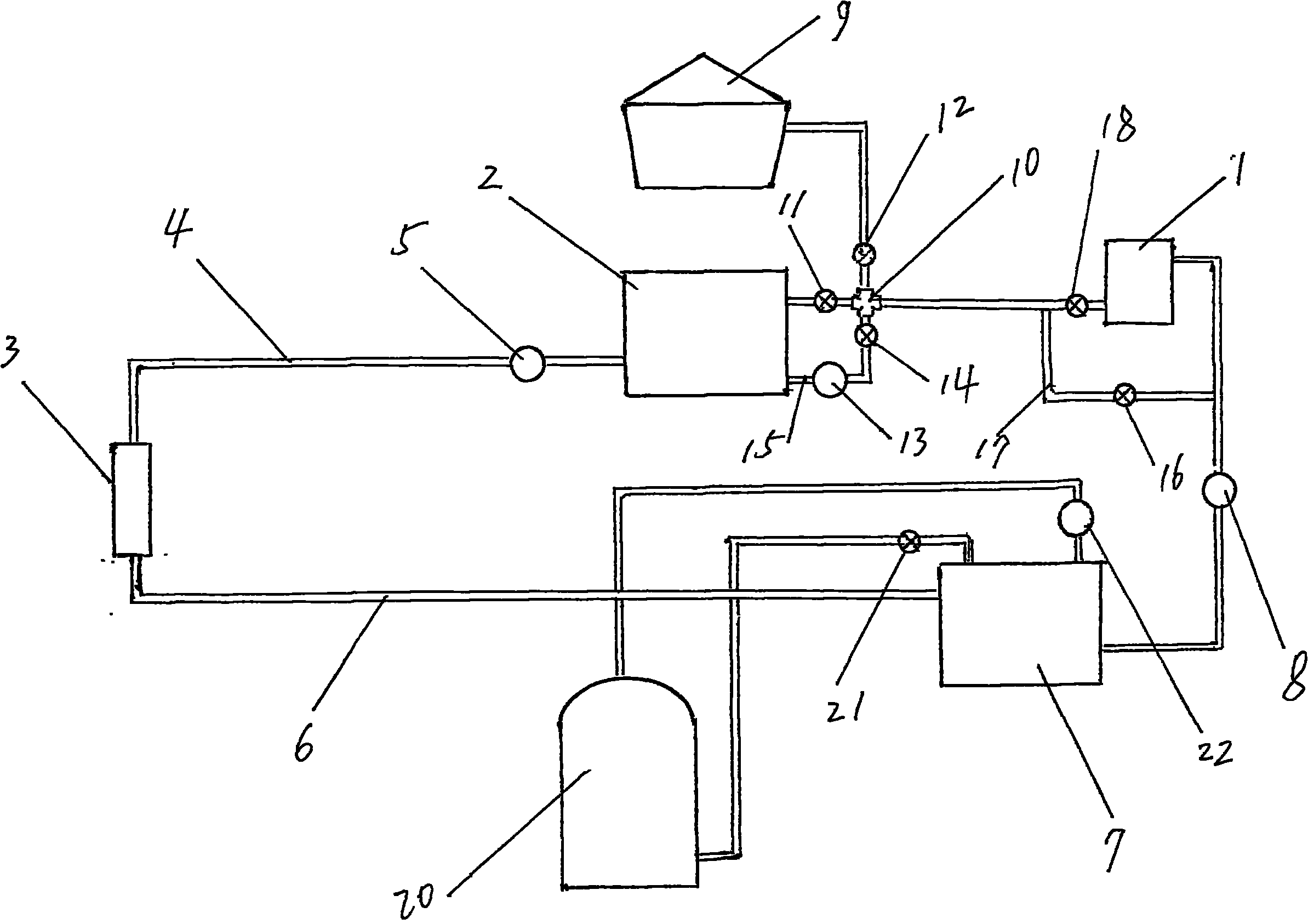

[0013] refer to figure 1 , figure 2 , the present invention includes a cold water mechanical refrigerator 1 of the prior art, a cold water tank 2 connected to the refrigerator, a heat exchanger 3 in the refrigeration production link, a cold water delivery pipeline 4 connecting the cold water tank and the heat exchanger, and a cold water pump 5 , connect the return water line 6 of heat exchanger 3 water outlets and refrigerator 1, the return water tank 7 and the return water pump 8 on the return water line, install air-drying tower 9 above the cold water tank, and air-drying tower selects stereotyped product for use. A four-way joint 10 is connected to the pipeline between the refrigerator 1 and the cold water tank 2, a valve 11 is arranged on the pipeline between the joint 10 and the cold water tank, and a water drying tower with a valve 12 is connected between the joint and the water inlet interface of the water drying tower The water inlet pipe connects the circulating wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com