Water-lubricating single screw compressor

A single-screw compressor and water-lubricated technology, applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of difficult casting, low yield, and reduced compressor efficiency, so as to facilitate casting and welding, Long service life, solve the effect of easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

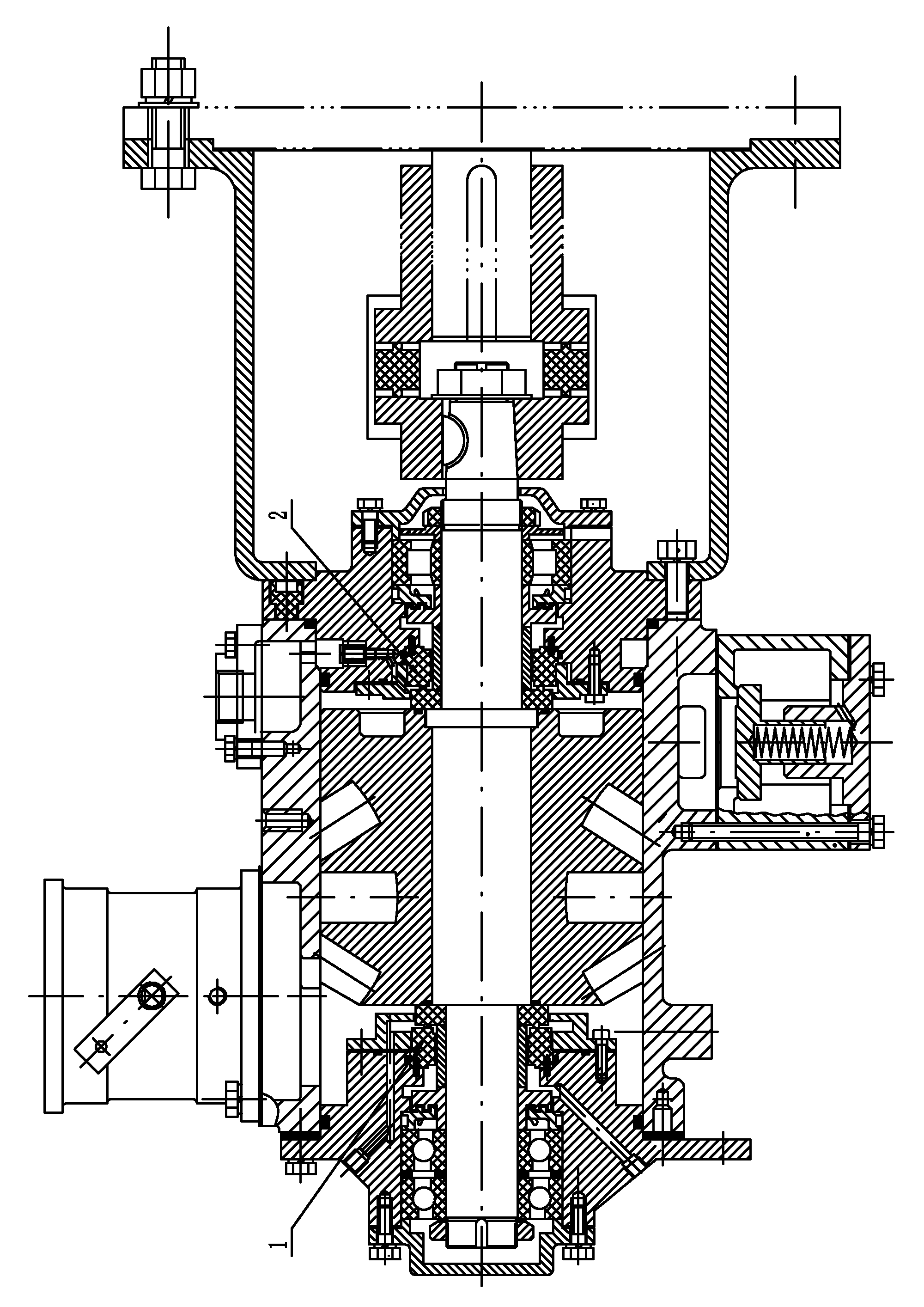

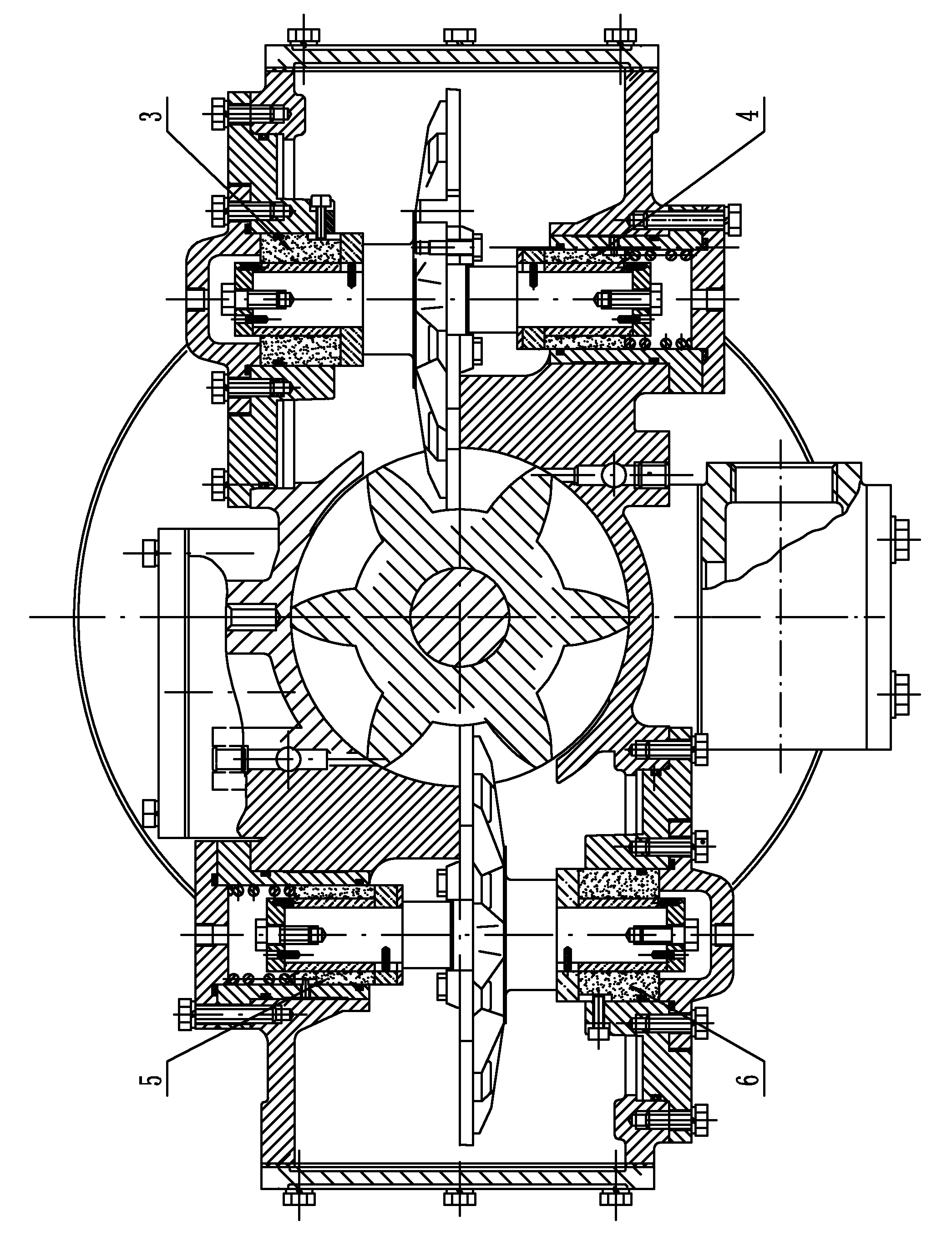

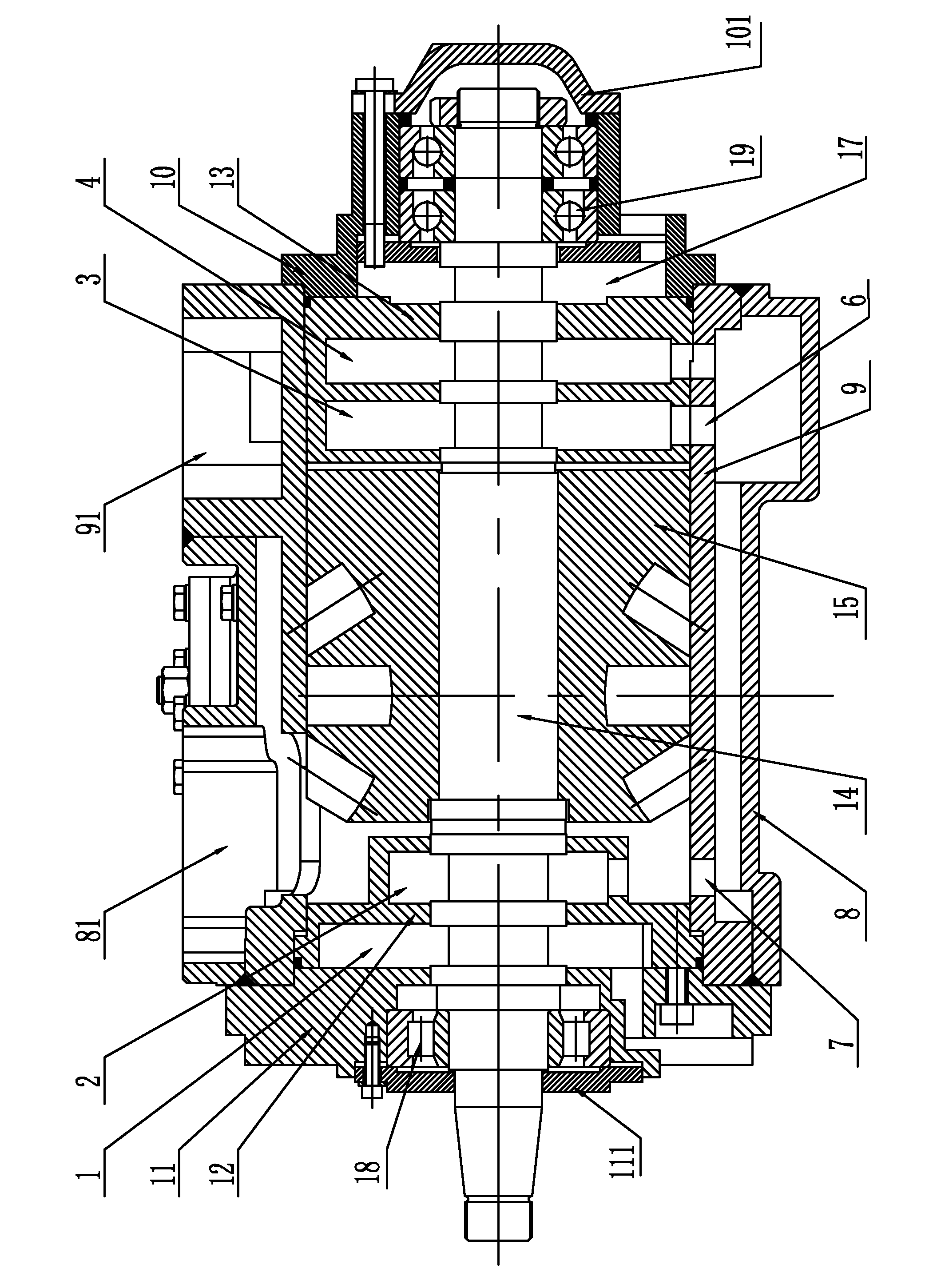

[0016] refer to image 3 , the inner cylinder 9 is tightly fitted in the body 8, wherein the air inlet 81 is integrally formed in the body 8, the exhaust port 91 is integrally formed in the inner cylinder 9, and the air inlet 81 and the exhaust port 91 are all arranged on the top of the body 8, The left part of the inner cylinder near the air inlet is the low-pressure end, and the right part of the inner cylinder near the exhaust port is the high-pressure end. The inner cylinder 9 is filled with a screw 15, and the left end of the screw shaft 14 is supported on the left bearing seat 11 through the left bearing 18. , the right end is supported on the right bearing seat 10 by the right bearing 19, the bearing seat 11 is provided with a bearing end cover 111, and the right bearing seat 10 is provided with a right bearing end cover 101. Two ends close to the screw shaft 14 are formed with a plurality of reduced-diameter ring grooves, which cooperate with the corresponding ring gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com