Automatic detergent feeding system

A technology of automatic dosing and detergent, applied in washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of high cost and complex structure, and achieve the effects of improving efficiency, simple structure and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

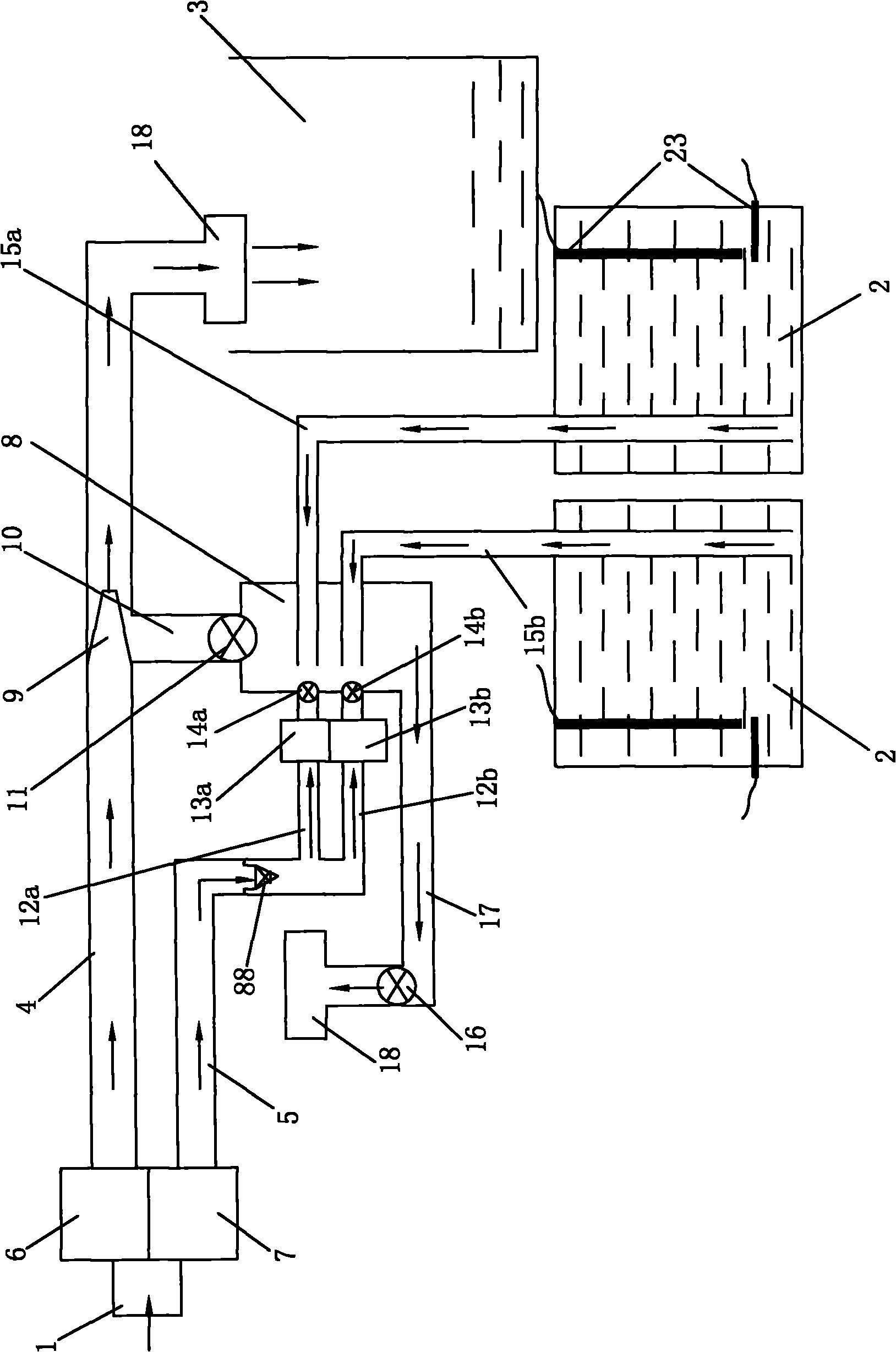

Embodiment 1

[0032] like figure 1 As shown, the cleaning control valve includes an electromagnet that generates a driving source and a rubber-wrapped magnet ball valve. The cleaning water path between the cleaning water valve 7 and the constant volume container 8 is provided with two shunts 12a corresponding to the two detergent containers. , 12b, the shunts 12a, 12b are respectively provided with electromagnets 13a, 13b, after the electromagnets 13a, 13b are energized, they can attract the magnet ball valves 14a, 14b to close the shunts 12a, 12b and open the constant volume container 8 and the detergent container 2 The passage 15a, 15b between, or the water inlet shock magnet ball valve 14a, 14b opens the shunt 12a, 12b between the cleaning water valve 7 and the constant volume container 8 and closes the passage between the constant volume container 8 and the detergent container 2 15a, 15b.

[0033] The one-way valve described in this embodiment is one, and is arranged on the main road o...

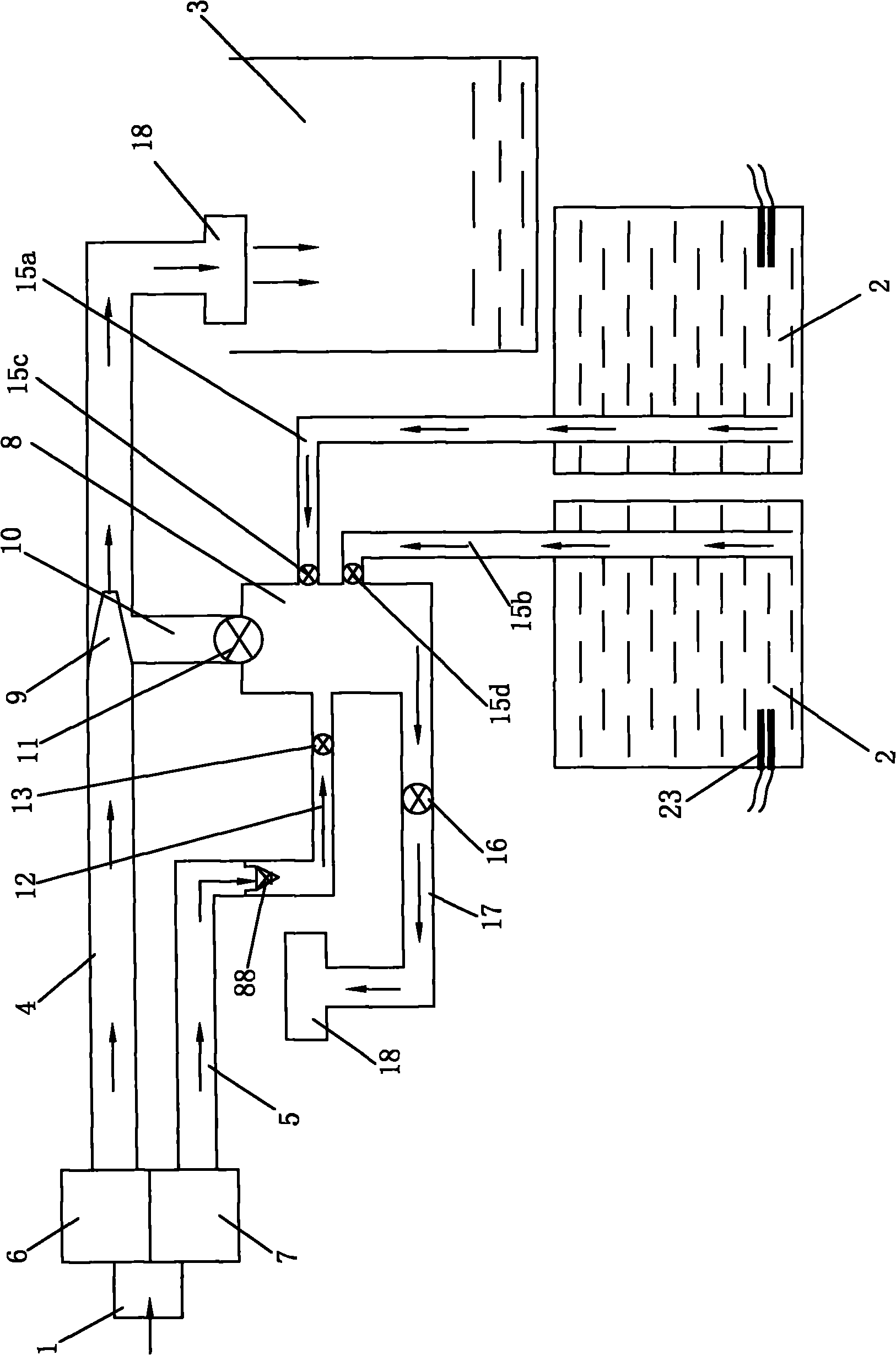

Embodiment 2

[0035] like figure 2 As shown, the cleaning control valve and the detergent control valve are all solenoid valves, the constant volume container 8 is connected with the detergent container 2 containing the washing liquid and softener respectively, and the passages 15a, 15b are connected to the constant volume container 8 Solenoid valves 15c and 15d are respectively arranged at each place. There is only one passage 12 between the cleaning water valve 7 and the constant volume container 8, and a solenoid valve 13 is also provided at the connection between the passage 12 and the constant volume container 8.

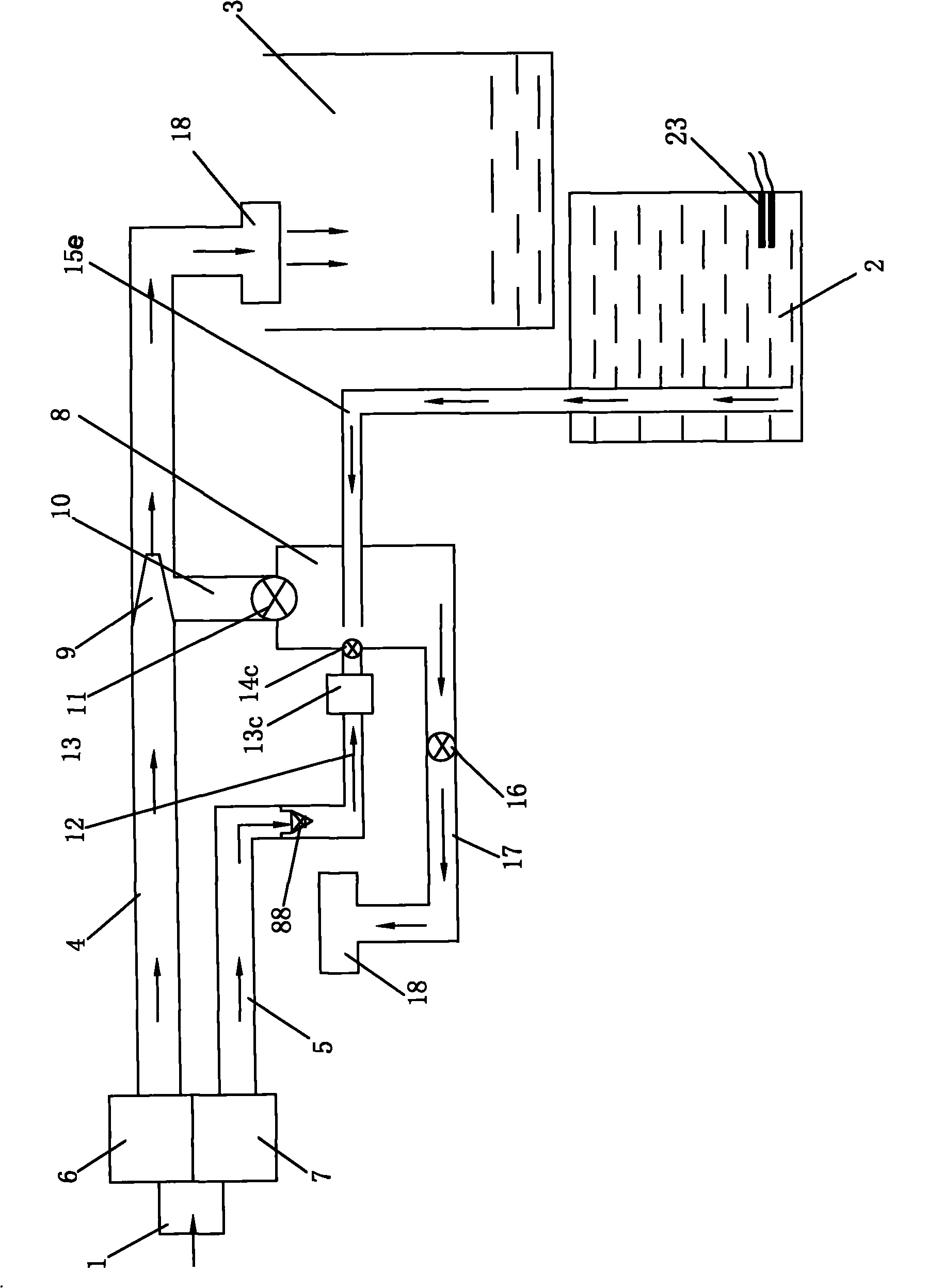

Embodiment 3

[0037] like image 3 As shown, this embodiment is different from Embodiments 1 and 2. There is only one passage 12 between the cleaning water valve 7 and the constant volume container 8, and there is only one detergent container. The passage 15e is between the detergent container and the constant volume container. The passage 12 is provided with an electromagnet 13c. After the electromagnet 13c is energized, it can attract the magnet ball valve 14c to close the passage 12 and open the passage 15e between the constant volume container 8 and the detergent container 2, or the incoming water impacts the magnet ball valve 14c to open the cleaning water. The passage 12 between the valve 7 and the constant volume container 8 closes the passage 15 e between the constant volume container 8 and the detergent container 2 .

[0038] The one-way valve described in the second and third embodiments above is one, and is arranged between the cleaning water valve and the cleaning control valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com