Method for online saponification and Ca<2+> removal of extracting agent used for rare earth separation

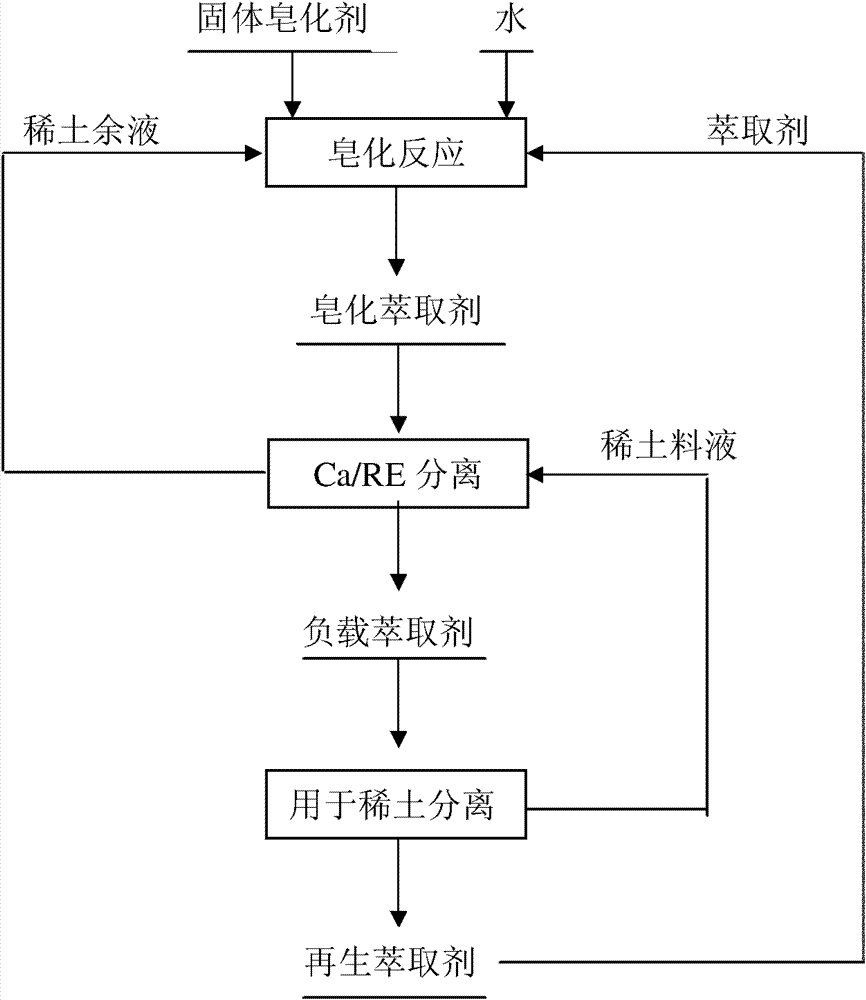

An extractant and a technology for saponifying extractant, which is applied in the field of online saponification and Ca2+ removal of extractant for rare earth separation, and achieves the effect of simple and continuous saponification process, saving turnover and reducing saponification cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] According to calcium oxide 292 g / min, water 5 liters / min, 1.5mol / L P 507 The feed rate of 20 liters / min of extractant is continuously and evenly fed into the saponification tank, fully stirred for 45 minutes, the saponification temperature is 15° C., and the phase separation in the saponification process is in good condition. clarified good P 507 Extractant, saponification value 0.51mol / L. The saponification extractant directly enters the Ca removal 2+ In the tank, after the exchange reaction with the rare earth material liquid, it contains Ca 2+ The rare earth residual liquid is returned to the saponification tank, and the loaded extractant enters the rare earth separation process. The extractant regenerated by stripping is returned to the saponification tank for saponification.

Embodiment 2

[0030] According to calcium hydroxide 410g / min, 1.5mol / L P 507 Extractant (extractant regenerated through stripping) 20 liters / min, water 3 liters / min feeding rate are given continuously and evenly in the saponification tank, meanwhile, will remove Ca 2+ Ca in the groove 2+ The rare earth residual liquid was led to the saponification tank, fully stirred for 55 minutes, the saponification temperature was 20°C, the phase separation was in good condition during the saponification process, and the saponification value of the extractant was 0.54mol / L. The saponification extractant directly enters the Ca removal 2+ In the tank, after the exchange reaction with the rare earth material liquid, it contains Ca 2+ The rare earth residual liquid is returned to the saponification tank, Ca 2+ Without entering the rare earth product, the loaded extractant enters the rare earth separation process. Return to the saponification tank for saponification after stripping and regeneration.

Embodiment 3

[0032] Feed continuously and evenly into the saponification tank by calcium carbonate 570 g / min, 0.6mol / L naphthenic acid extractant (extractant regenerated through stripping) 20 liters / min, water 4 liters / min, and simultaneously , will remove Ca 2+ Ca in the groove 2+ The rare earth residual liquid was introduced into the saponification tank, fully stirred for 65 minutes, the saponification temperature was 25°C, the phase separation was in good condition during the saponification process, and the saponification value of the extractant was 0.56mol / L. The saponification extractant directly enters the Ca removal 2+ In the tank, after the exchange reaction with the rare earth material liquid, it contains Ca 2+ The rare earth residual liquid is returned to the saponification tank, Ca 2+ Without entering the rare earth product, the loaded extractant enters the rare earth separation process. Return to the saponification tank for saponification after stripping and regeneration. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com