Green synthetic method of controllable superfine metal oxide/carbon nano tube composite material

A composite material, metal salt technology, applied in the field of green synthesis of controllable ultrafine metal oxide/carbon nanotube composites, can solve the precise variables of nanoparticle growth, poorly understood, difficult nanoparticle growth rate, limitations Application performance research and other issues, to achieve uniform and stable solid loading, simple preparation technology, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

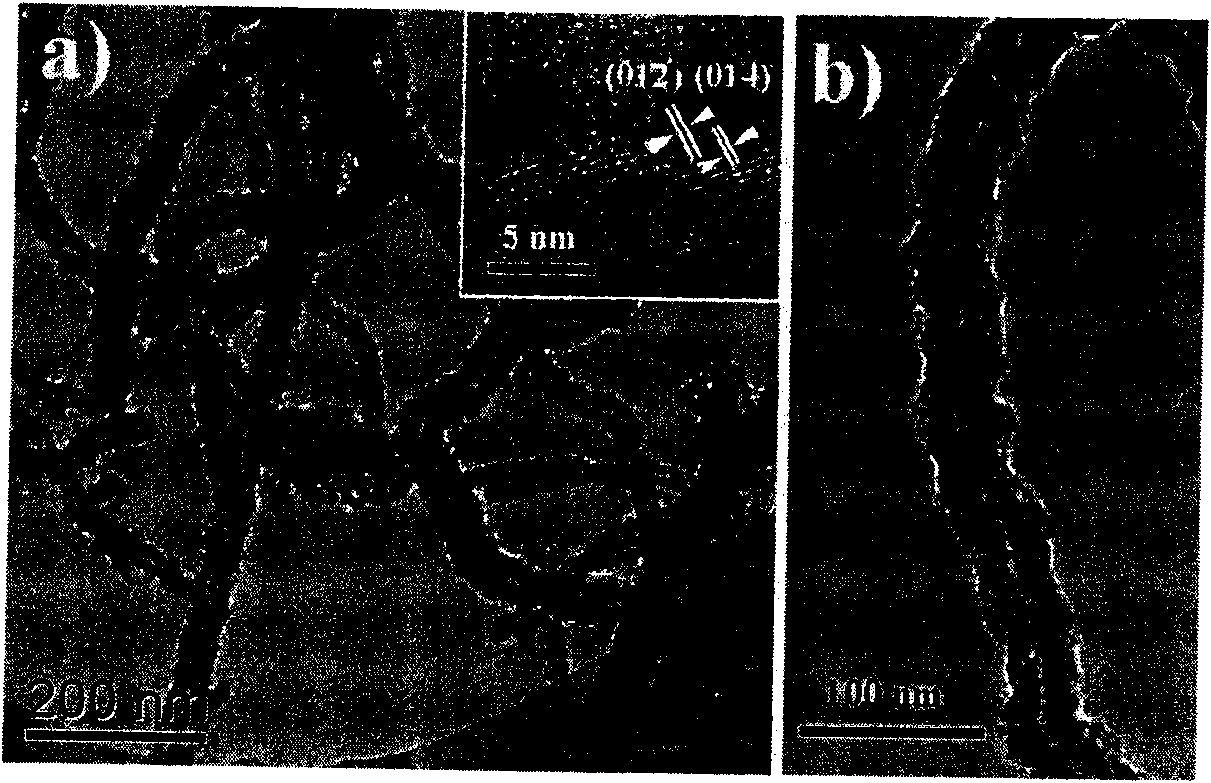

[0015] Example 1: 3.75mmol TiOCl 2 And 0.5mL of concentrated hydrochloric acid in 9mL N, N dimethylformamide (DMF) solvent prior reaction to form a hydrated hydrochloric acid double salt precursor, add 1.68g of phenol and 0.3g of acid-treated multi-walled carbon tubes (MWCNT) , the mixture was slowly reacted in an oil bath at 65-70°C for 2-6 days, and the product was filtered, washed, and dried naturally to obtain TiO 2 / CNT composites.

example 2

[0016] Example 2: 0.78g ZrOCl 2 ·8H 2 O and 0.5mL of concentrated hydrochloric acid were reacted in advance in 9mL of N,N dimethylformamide (DMF) solvent to form a hydrated hydrochloric acid double salt precursor, and 1.14g of phenol and 0.3g of acid-treated multi-walled carbon tubes (MWCNT ), the mixture was slowly reacted in an oil bath at 70-90°C for 2-4 days, and the product was filtered, washed, and dried naturally to obtain ZrO 2 / CNT composites.

example 3

[0017] Example 3: 1.515g Fe (NO 3 ) 3 9H 2 O was dissolved in 100mL of N,N dimethylformamide (DMF) solvent, 1.14g of phenol and 0.3g of acid-treated multi-walled carbon tubes (MWCNT) were added, and the resulting suspension was transferred to a in a polytetrafluoroethylene reactor and placed in an oven at 180°C for a constant temperature reaction of 1-3 days, the product was filtered, washed, and naturally dried to obtain Fe 2 o 3 / CNT composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com