Priming method and priming apparatus

A technology for initiating filling and processing methods, applied to devices, optics, instruments, etc. for coating liquid on the surface, which can solve a large number of problems and achieve the effect of reducing usage, ensuring reliability, and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

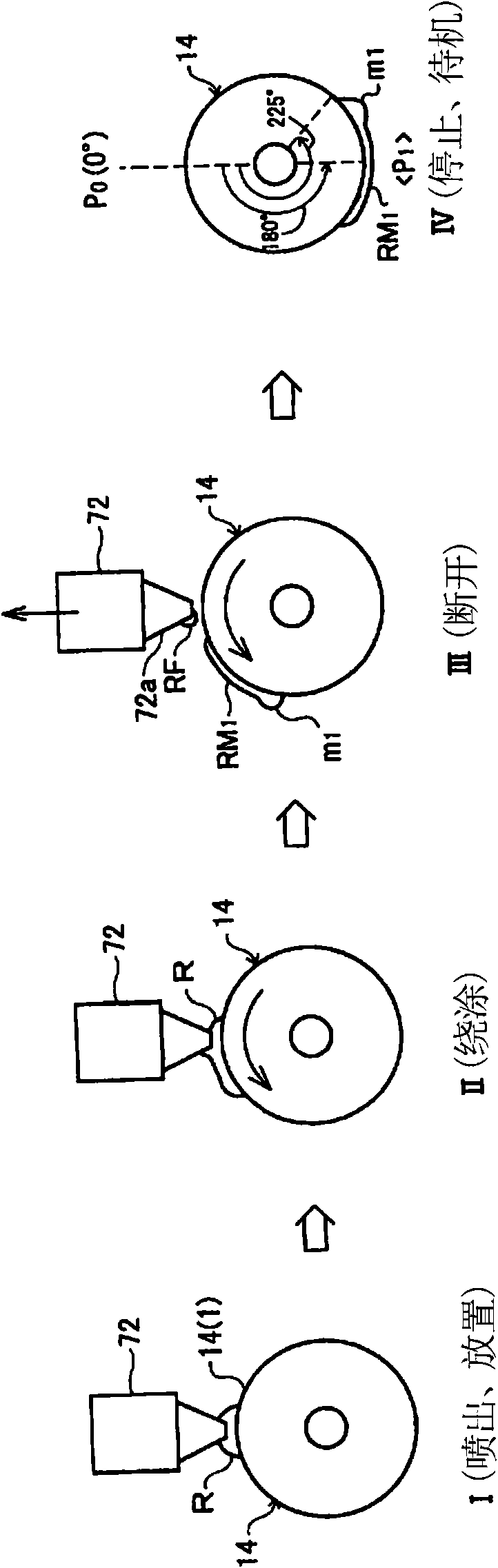

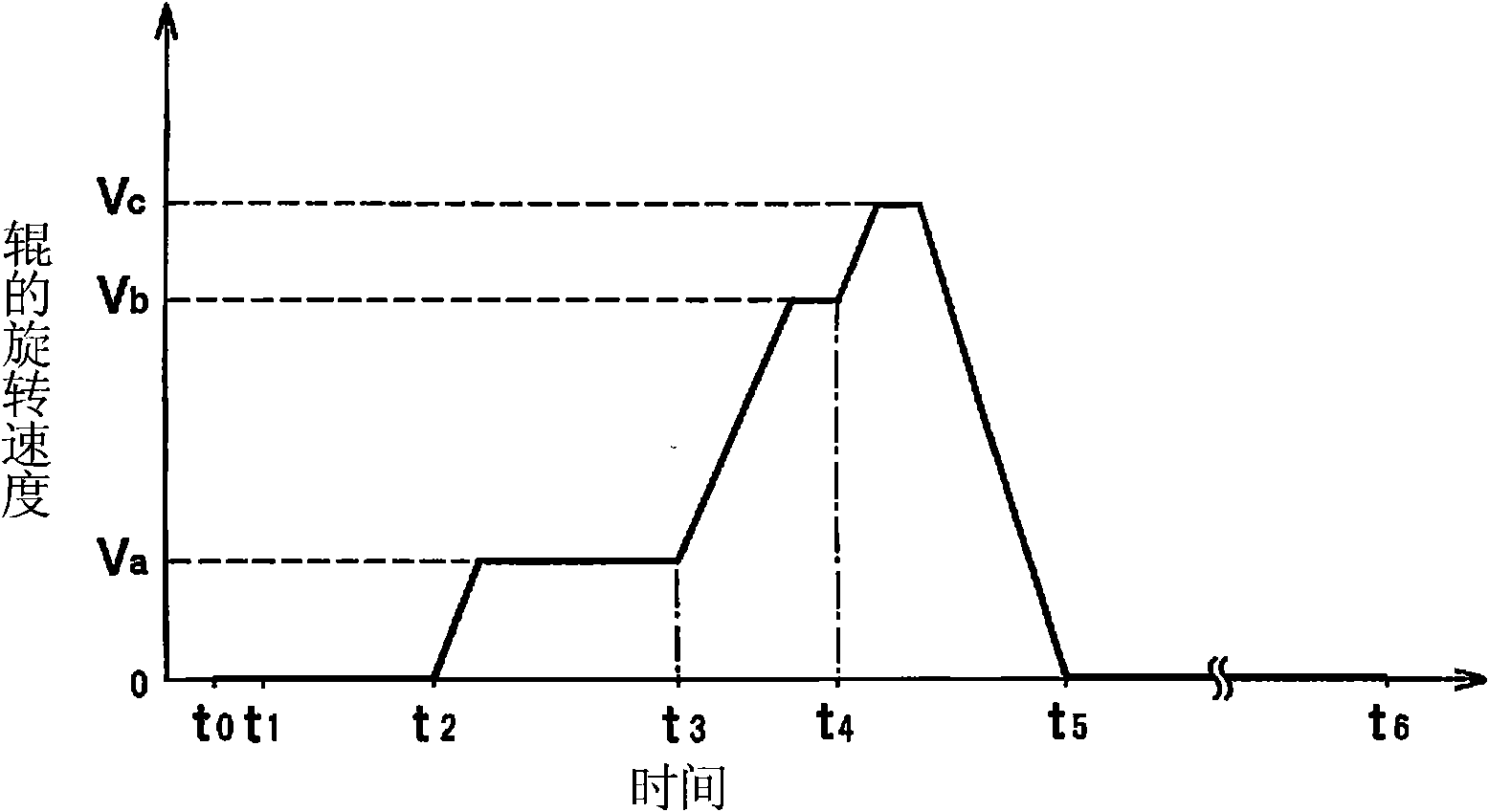

[0039] Next, preferred embodiments of the present invention will be described with reference to the attached drawings.

[0040] Structure of the start-up filling processing unit

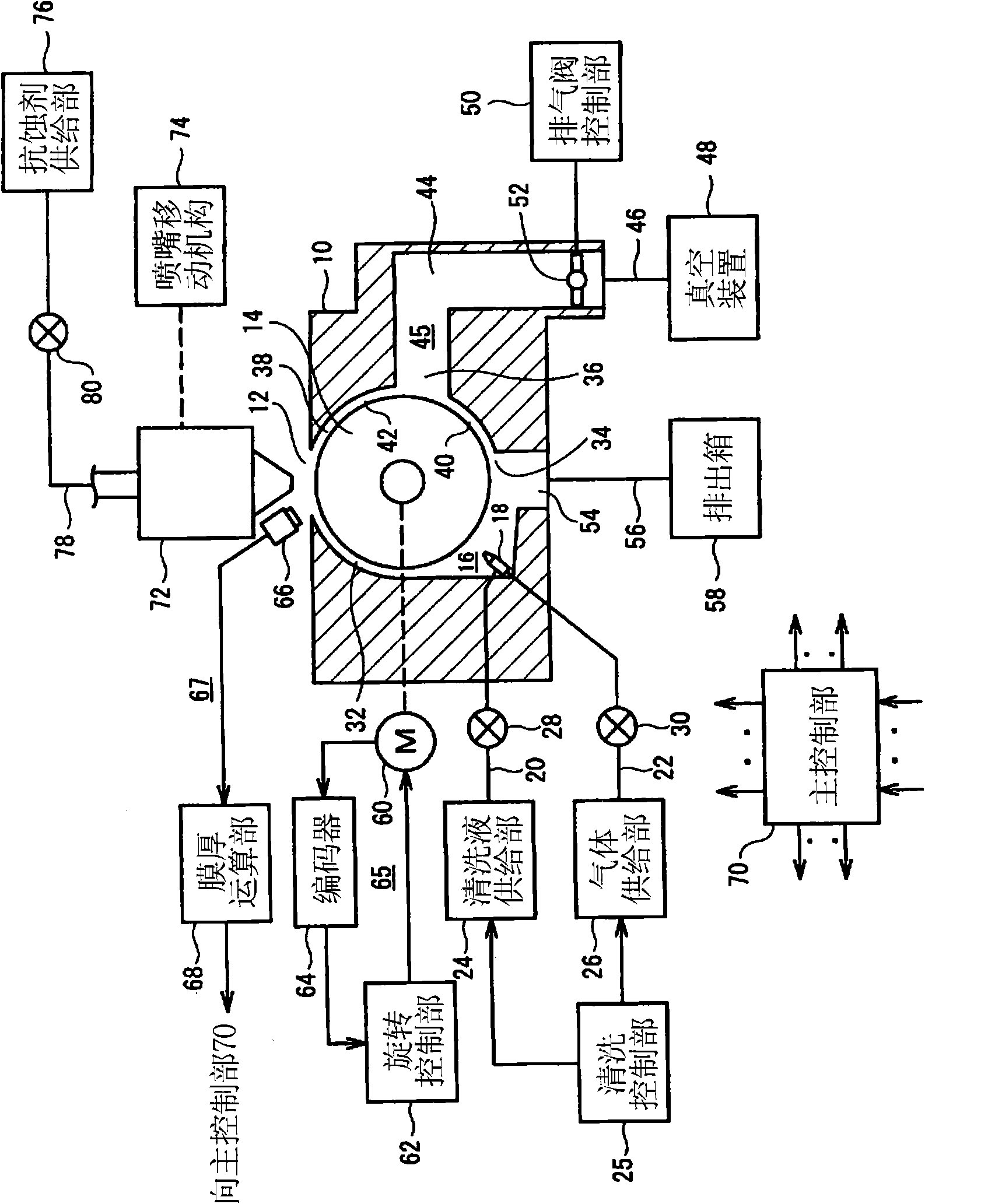

[0041] figure 1 It is a figure which shows the structure of the priming processing apparatus which concerns on one Embodiment of this invention. This priming processing device is incorporated in a resist coating device (not shown) that performs resist coating by a non-spin coating method, for example, in a photolithography process for an LCD manufacturing process. coating process, and the priming processing device is disposed near a coating table (not shown) on which a substrate to be processed is placed or suspended for the resist coating process.

[0042] In the illustrated priming processing device, the casing 10 is composed of a long frame having a slit-shaped opening 12 on the upper surface, and the top of the casing 10 passes through the opening with the accommodating priming roller 14 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com