Method and device for vaporizing hydrogen chloride in tail gas in polycrystalline silicon production

A hydrogen chloride and polysilicon technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high power consumption, difficulty in stable control of hydrogen chloride purity, loss, etc., achieve good vaporization effect, save equipment costs and The effect of electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

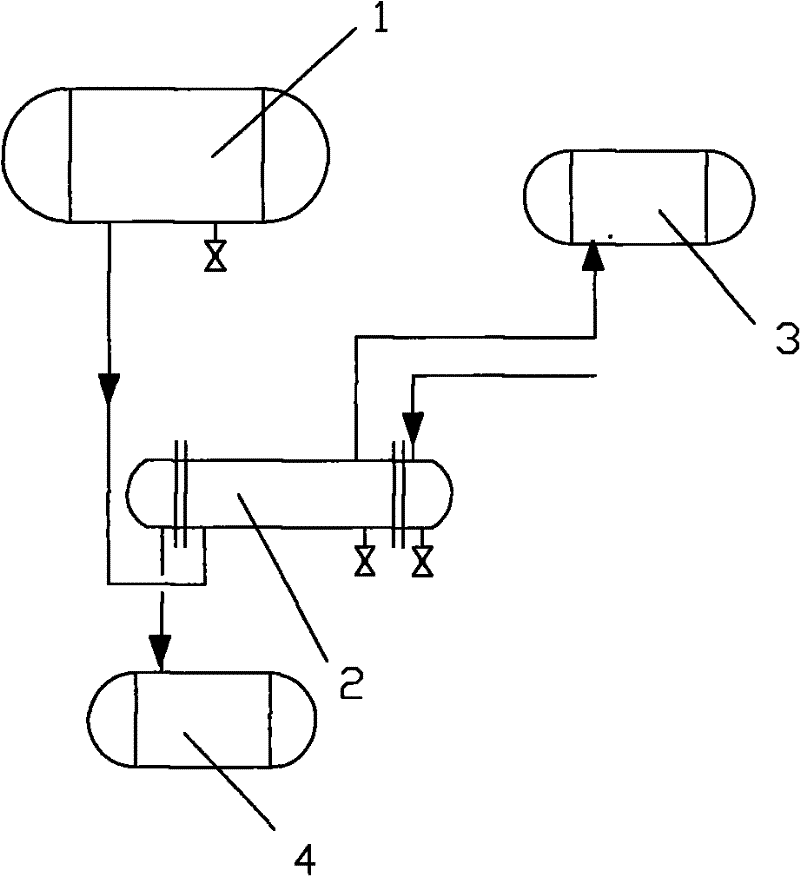

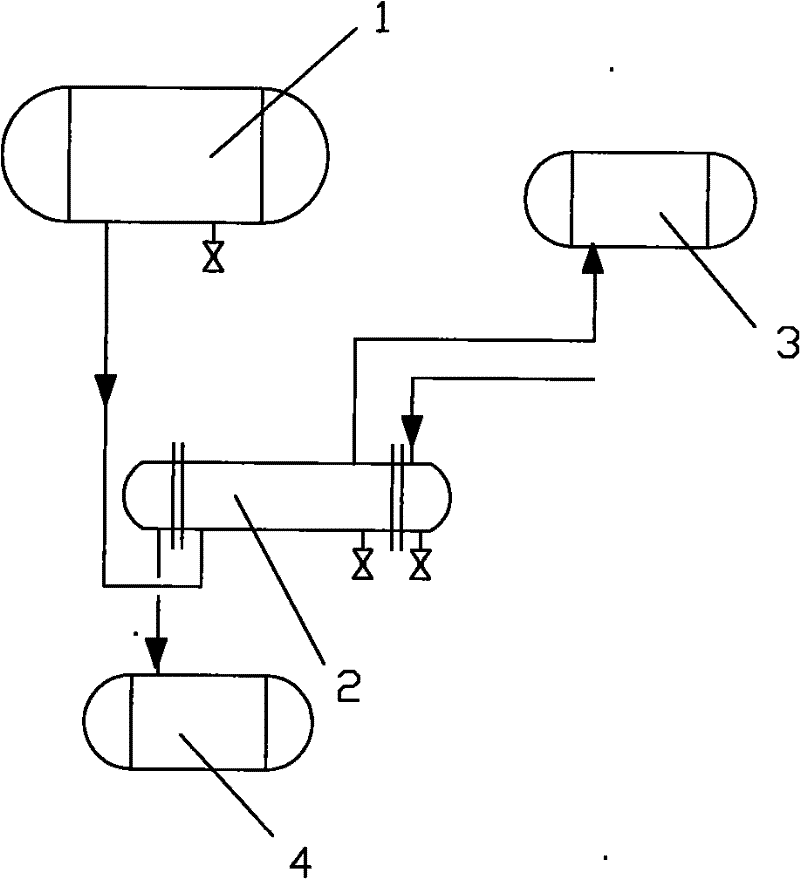

[0013] see figure 1 , a device for hydrogen chloride in the vaporized tail gas in polysilicon production, including a hydrogen chloride condensation storage tank 1, a heat exchanger 2 and a demister 3 connected in sequence, and a chlorosilane storage tank 4 connected to it is arranged below the heat exchanger 2 for storage. A small amount of chlorosilane liquid separated from liquid hydrogen chloride.

[0014] First, transfer the low-temperature hydrogen chloride liquid from the top of the hydrogen chloride separation tower to the hydrogen chloride condensation storage tank 1, and pass the low-temperature hydrogen chloride liquid in the hydrogen chloride condensation storage tank 1 and the high-temperature chlorosilane liquid separated from the bottom of the hydrogen chloride separation tower through a heat exchanger 2 After heat exchange, the low-temperature hydrogen chloride liquid is vaporized and separated from a small amount of chlorosilane liquid entrained in it, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com