Steam mop boiler

A boiler and mop technology, applied in the direction of cleaning carpets, floors, household appliances, etc., can solve the problems of small vaporization area, and achieve the effects of large vaporization area, good vaporization effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

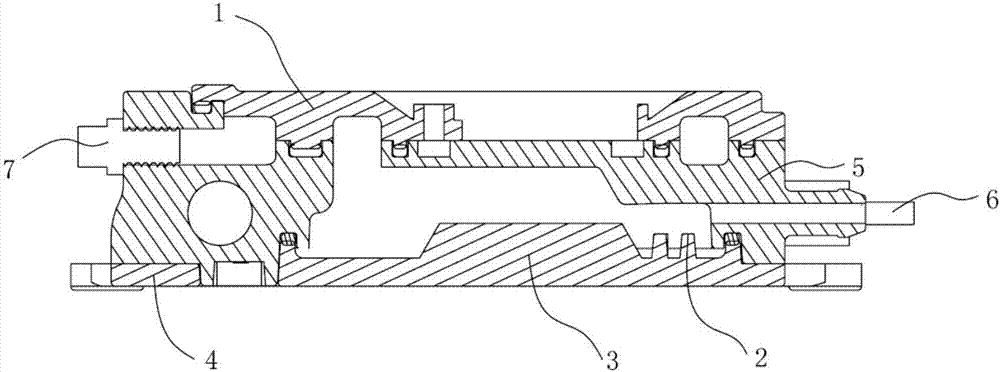

[0012] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0013] Such as figure 1 As shown, a steam mop boiler of the present invention includes an upper casing 1, a heating plate 2, a boiler body 3, a temperature detection device 4 and a heating tube 5; one end of the boiler body 3 is provided with a water inlet 6, and the other end is provided with There is a steam outlet 7; the heating pipe 5 is directly die-casted with the boiler body 3; the upper shell 1 is clamped and fixed with the boiler body 3; the temperature detection device 4 is arranged on the boiler body 3- Side; the heating plate 2 is set in the boiler body 3 .

[0014] The upper casing 1 is made of aluminum alloy. The heat pipe 5 is made of copper.

[0015] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com