Method for forecasting and producing narrow hardenability strip steel by hardenability

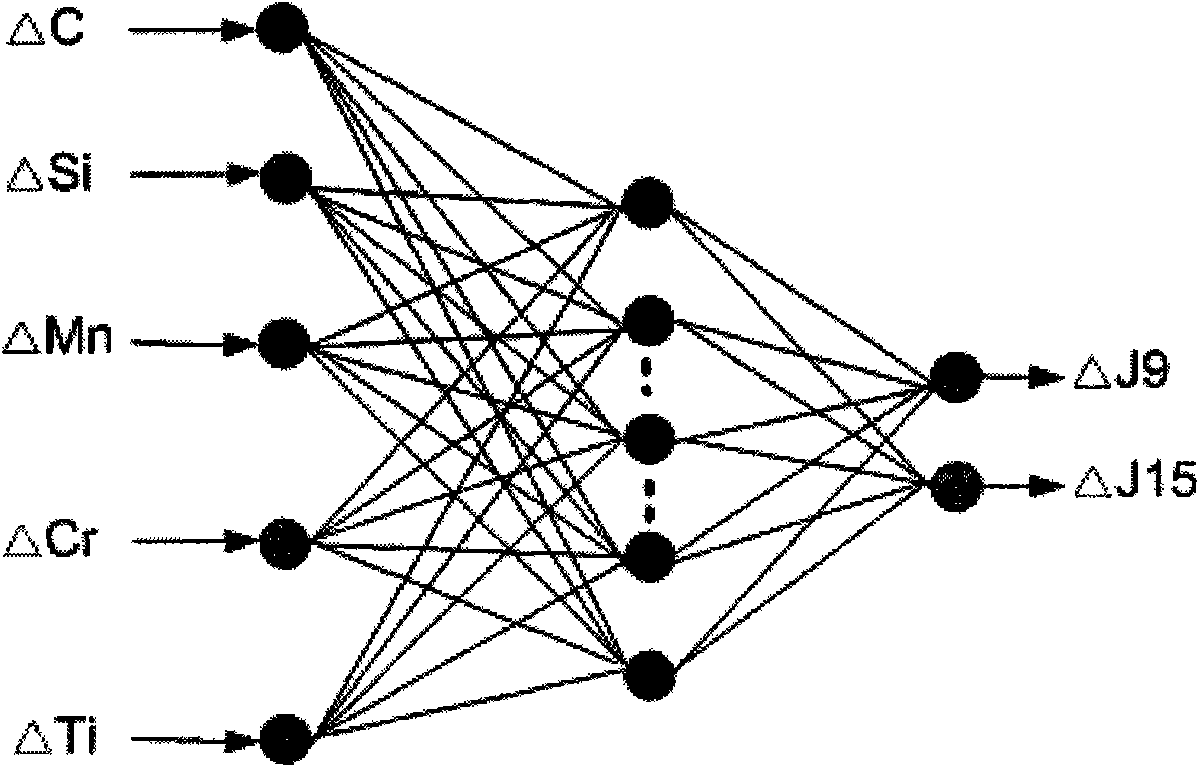

A hardenability belt and hardenability technology, applied in biological neural network models, special data processing applications, instruments, etc., can solve the problem of low control accuracy and difficulty in meeting the control requirements of high-quality end-quenched steel narrow hardenability belts, etc. It can achieve the effect of simplifying complex nonlinear mapping function relationship, improving forecast accuracy, and eliminating system deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

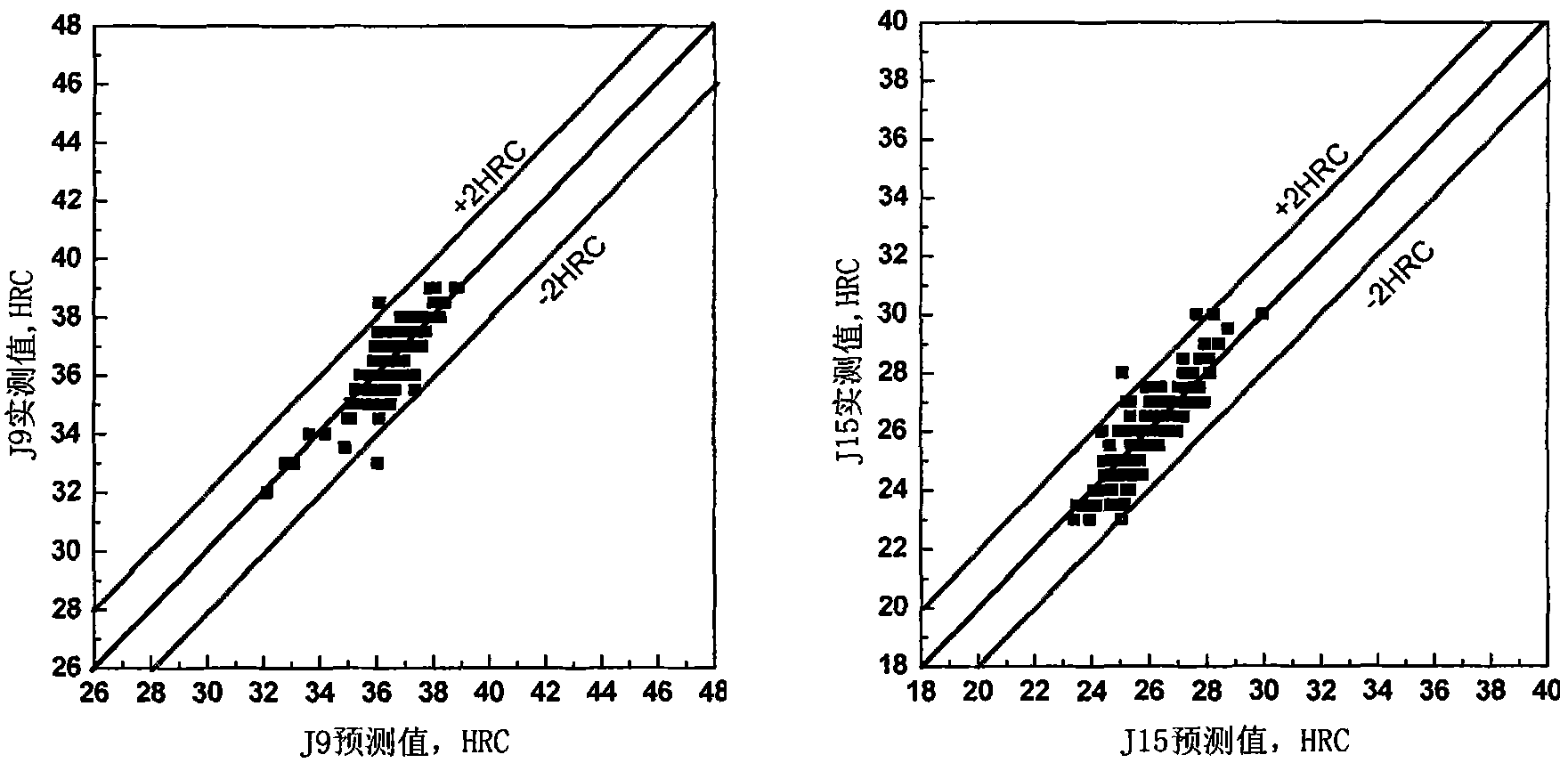

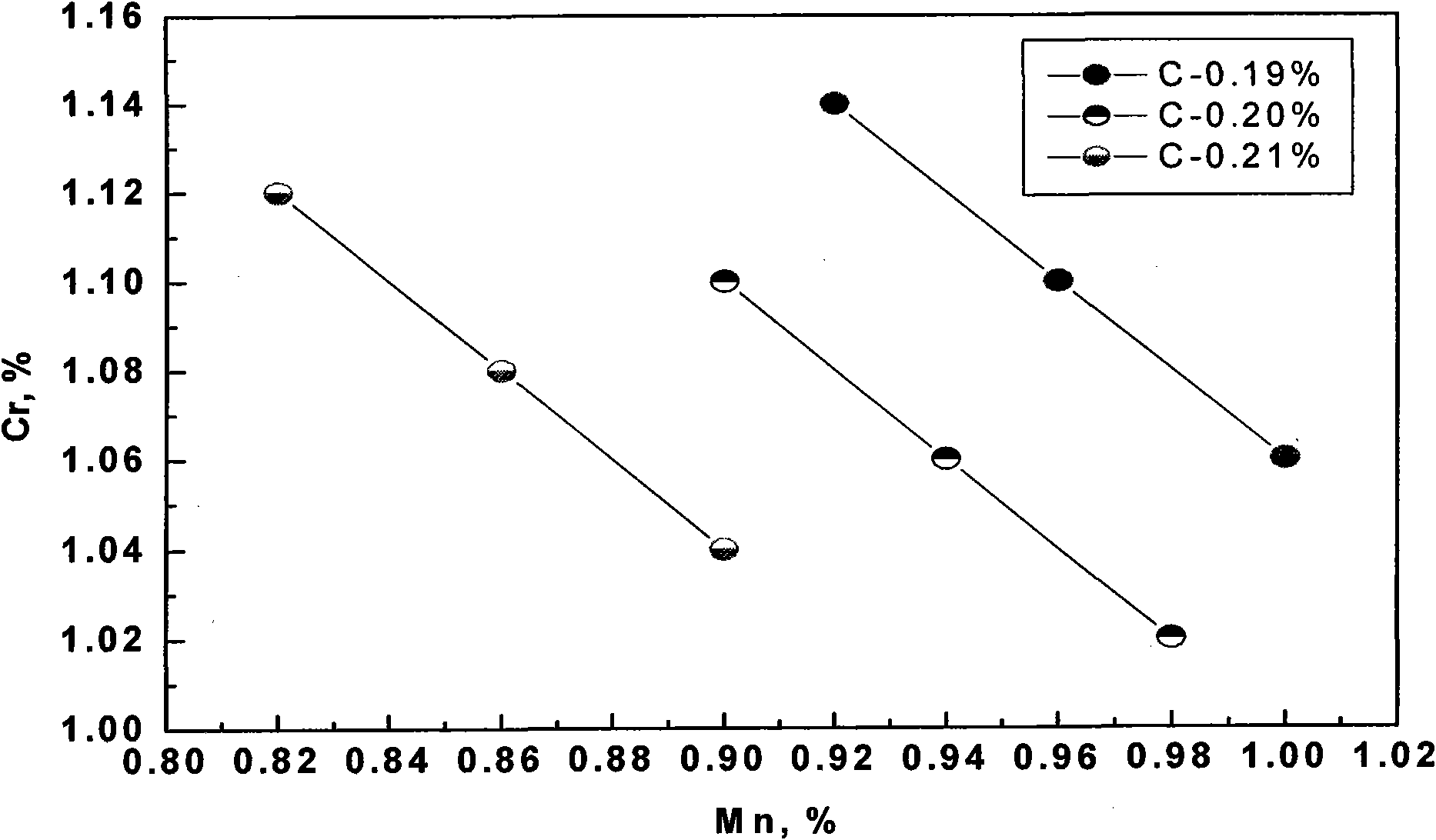

[0021] Take the narrow hardenability zone control of gear steel 20CrMnTiH as an example. The national standard GB / T5216-2004 stipulates the range of end quenching value: J9 value is 30~42HRC, J15 value is 22~35HRC. When the customer places an order according to the middle limit 4HRC range of J9 and J15 values, that is, the J9 value is 34-38HRC, and the J15 value is 27-31HRC, the production of narrow hardenability steel should be realized as follows.

[0022] Schedule description:

[0023] Table 1 shows the influence coefficients of each element of 20CrMnTiH on J9 and J15 values in a method for hardenability prediction and production of narrow hardenability steel strip according to the present invention.

[0024] Table 2 shows the target composition and control accuracy range of 20CrMnTiH in a hardenability forecast and a method for producing narrow hardenability strip steel in the present invention.

[0025] Table 3 is a 20CrMnTiH alloying charging calculation model for a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com