Heat-exchange dedusting device

A technology of dust removal device and connection device, which is applied in the direction of heat exchanger type, indirect heat exchanger, lighting and heating equipment, etc., can solve the problems of dust can not be removed, single function, and the results of use cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

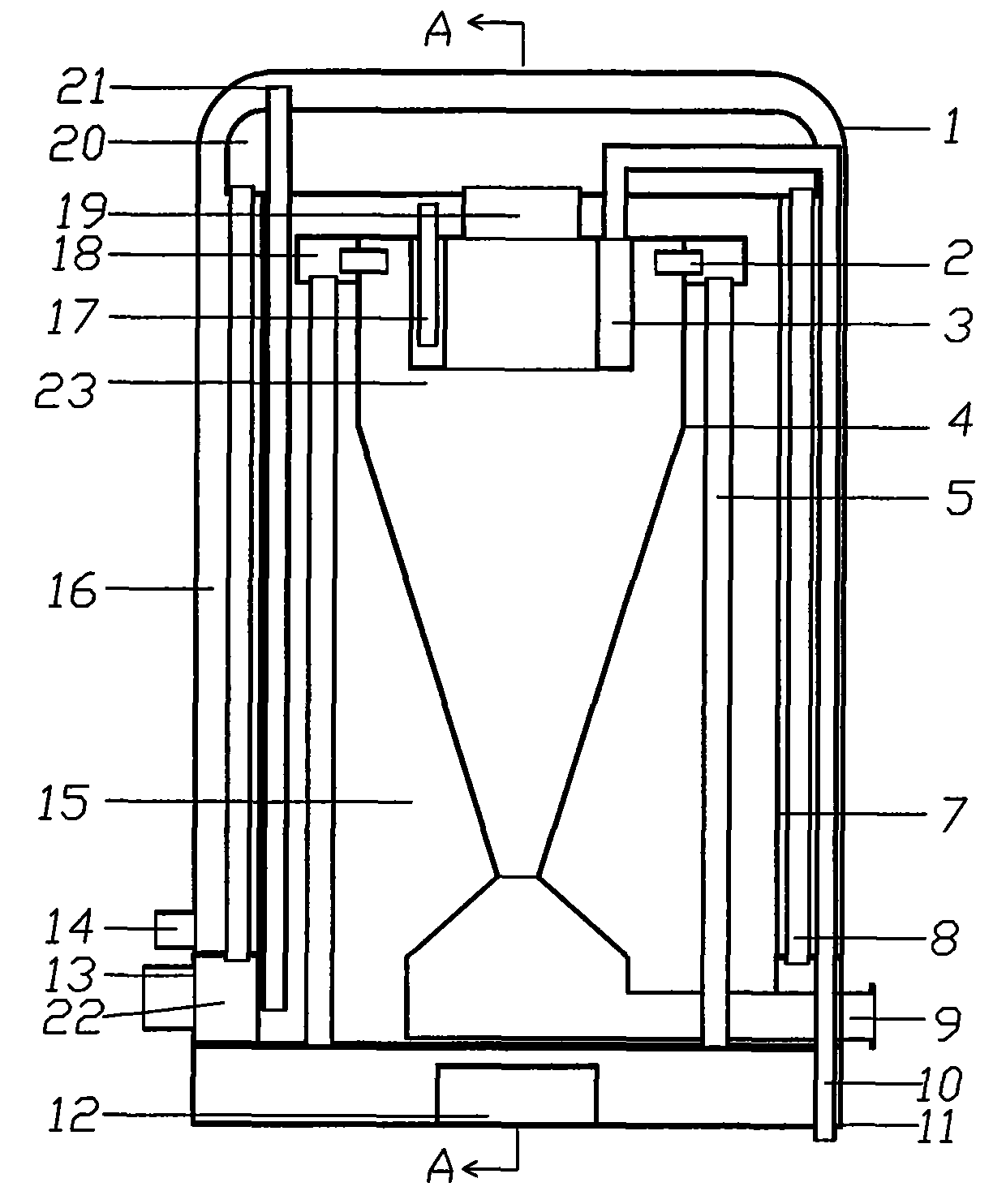

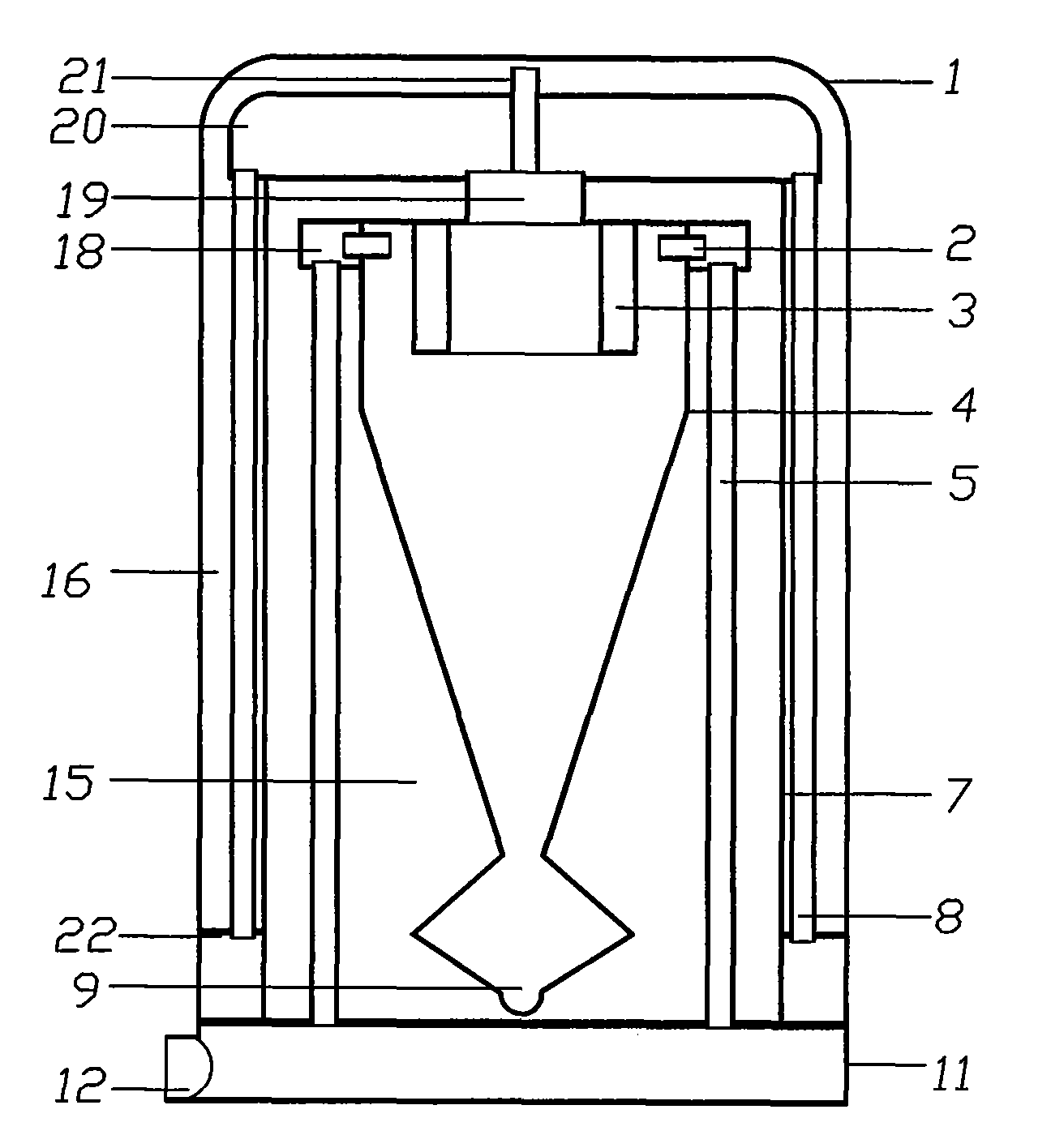

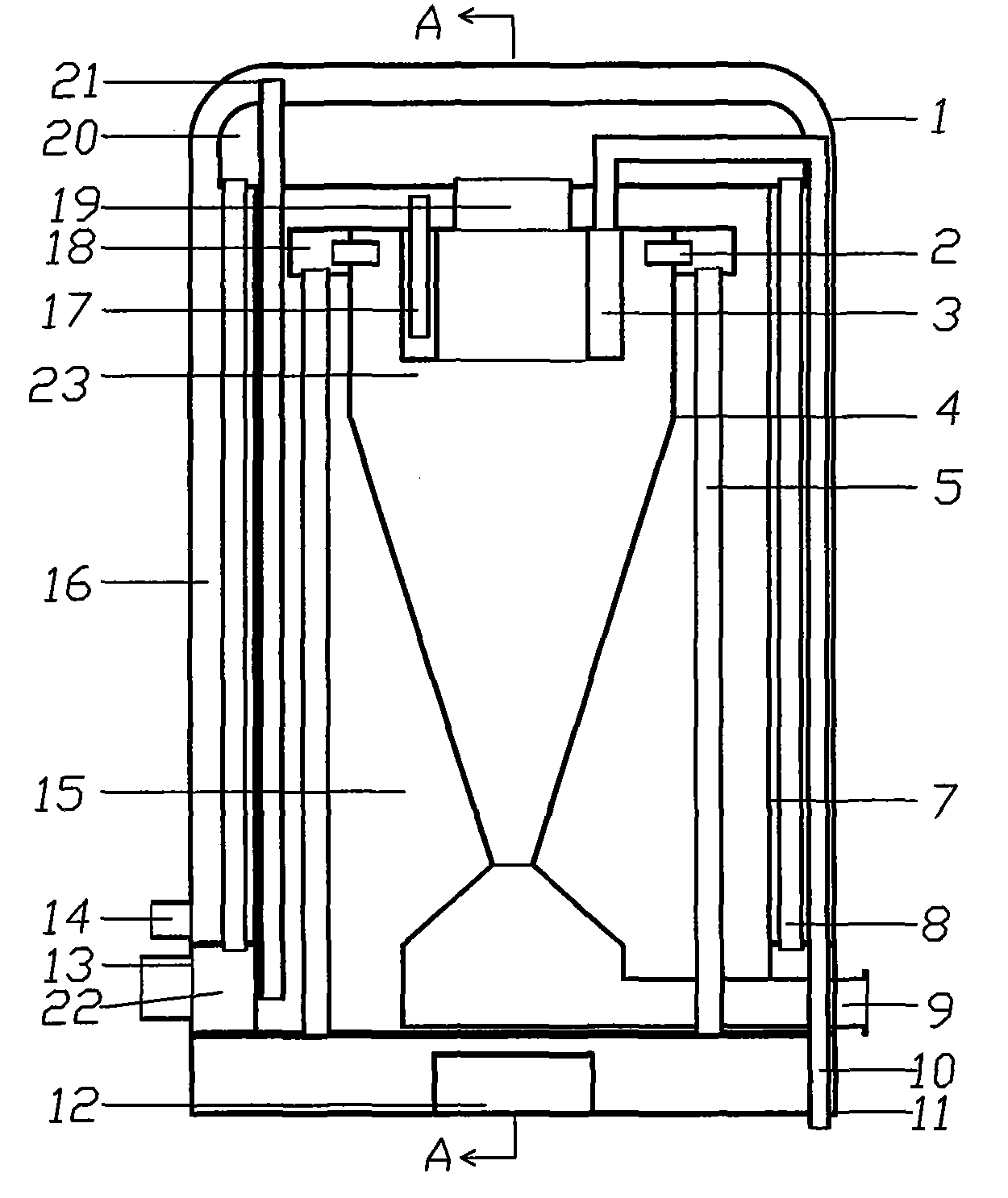

[0010] Such as figure 1 , figure 2 The shown heat exchange dedusting device includes a housing 1 with a connecting device 11 at the lower end of the housing, a hot gas inlet 12 on the connecting device 11, a water inlet 14 at the lower part of the housing, and a separation partition 7 inside the housing. The 7 separating partitions are the cold water area 16, and the inside of the separating partition is the warm water area 15. There is an upper smoke chamber 20 on the upper part of the shell, a lower smoke chamber 22 on the lower part of the shell, and a smoke outlet 13 on the lower smoke chamber. There is a dust removal device 4 inside, and there is a dust removal port 9 below the dust removal device. An isolation interlayer retaining ring 23 is installed on the upper part of the dust removal device. Inside the isolation interlayer retaining ring is a hot water area 3. The smoke outlet 19 of the dust removal device is located in the center of the isolation interlayer retain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com