Capture hood

A technology for collection hoods and production equipment, applied in the field of collection hoods, which can solve the problems of small airflow slopes and the inability to realize obliquely upwardly directed airflows, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

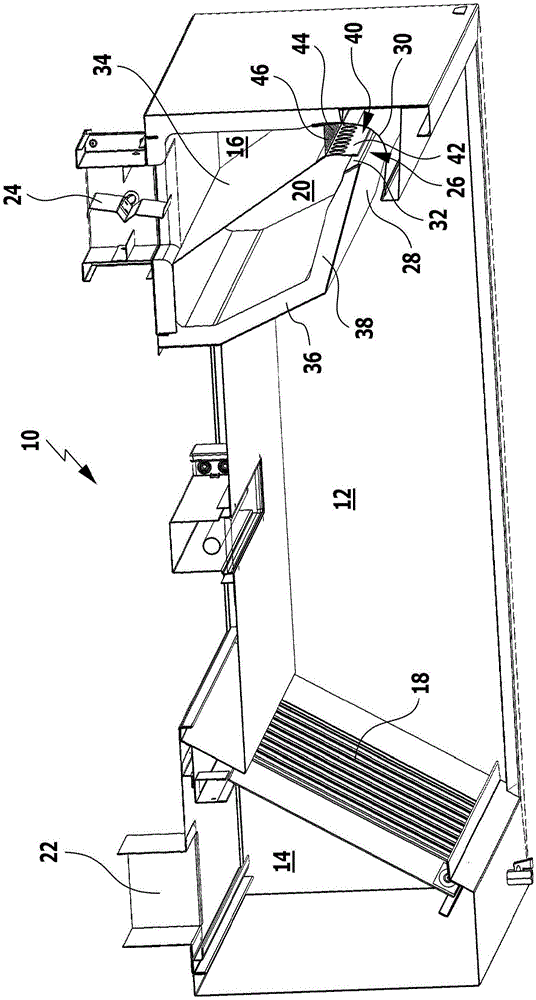

[0036] figure 1 A perspective view of an embodiment of a collecting hood according to the invention is shown, generally designated 10 . The collecting hood 10 itself extends in a longitudinal direction which extends approximately perpendicularly to the plane of the drawing. For better visibility, the figure 1 Only one section of the collecting hood 10 is shown in FIG.

[0037] The collecting hood 10 comprises a centrally arranged fume chamber 12 which is open downwards and tapers upwards. A suction chamber 14 and an air supply chamber 16 are arranged on both sides of the smoke chamber 12 , wherein the suction chamber 14 is separated from the smoke chamber 12 by a separator 18 and is arranged between the smoke chamber 12 and the air supply chamber 16 There is a low pressure chamber 20 . The smoke chamber 12 , the suction chamber 14 , the air supply chamber 16 and the low-pressure chamber 20 extend horizontally and parallel to one another in the longitudinal direction.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com