Quick assembly and disassembly type steel pipeline extrusion cut-off device

A intercepting device, assembly and disassembly technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of harmful and dangerous medium loss, inability to handle large-diameter steel pipes, inconvenient disassembly, etc. , to quickly cut off or reduce the medium flow, prevent the further expansion of the accident, and achieve the effect of safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

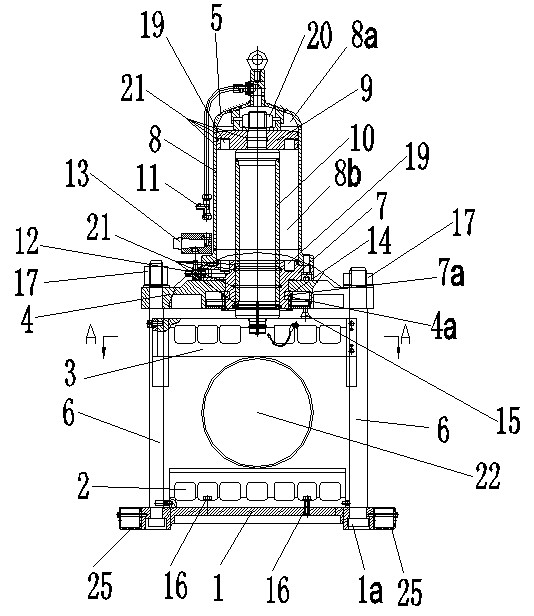

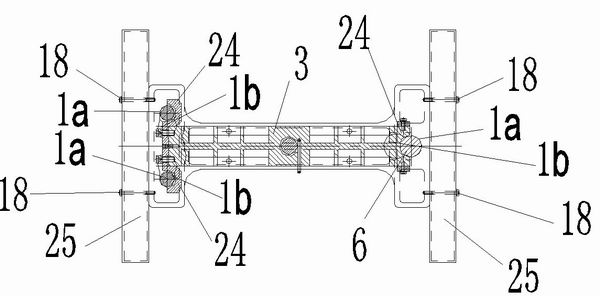

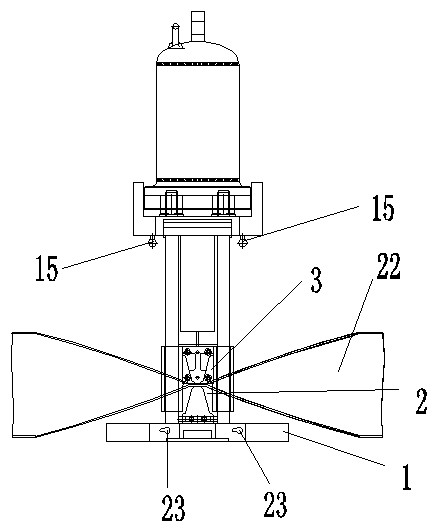

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0020] like figure 1 Shown is a quick assembly and detachable steel pipeline extrusion shut-off device, which consists of a base 1, a fixed knife edge 2, a movable knife edge 3, a beam 4, a hydraulic cylinder 5, a column 6, a piston 9, a piston rod 10 and corresponding connectors composition. The hydraulic cylinder 5 is composed of a cylinder head 7 and a cylinder body 8 . The base 1, the fixed knife edge 2, the movable knife edge 3, the beam 4, and the hydraulic cylinder 5 are arranged sequentially from bottom to top, and the fixed knife edge 2, the movable knife edge 3 and the beam 4 are parallel to each other. The left and right sides of the plane on the base 1 are vertically inserted with columns 6, and the fixed knife edge 2 and the moving knife edge 3 are arranged between the left and right side columns 6. Fixed knife edge 2 is installed on the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com