Electric control device system for mining elevator and control method thereof

A control method and technology of electronic control devices, applied in general control systems, electrical program control, control/regulation systems, etc., can solve problems such as hidden dangers in production safety, inability to stop, and lack of any protection system, so as to improve production efficiency and prevent The effect of further expansion of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

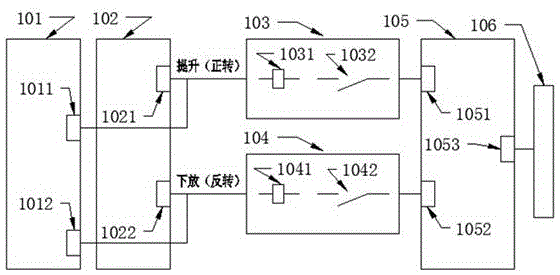

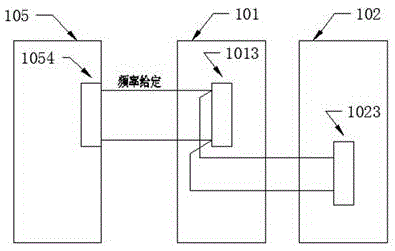

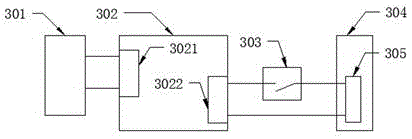

[0023] The electronic control device system is composed of five parts: motor forward and reverse running control, inverter frequency setting, working gate control, safety gate control and two-wire system control.

[0024] Such as figure 1 As shown, the forward and reverse operation control part of the motor includes: the first PLC (101), the second PLC (102), the first relay (103), the second relay (104), the frequency converter (105), and the motor (106); The first output point (1011) of the first PLC (101) and the first output point (1021) of the second PLC (102) are connected to the control coil (1031) of the relay one (103). The open contact (1032) is connected to the forward rotation control port (1051) of the inverter (105), the second output point (1012) of the first PLC (101) and the second output po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com