Safe fuel gas metering device with over-temperature cut-off function

A technology of cutting off function and gas metering, applied in the direction of measuring device, safety valve, valve device, etc., can solve problems such as accident expansion and secondary injury of personnel, and achieve the effect of avoiding accident expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

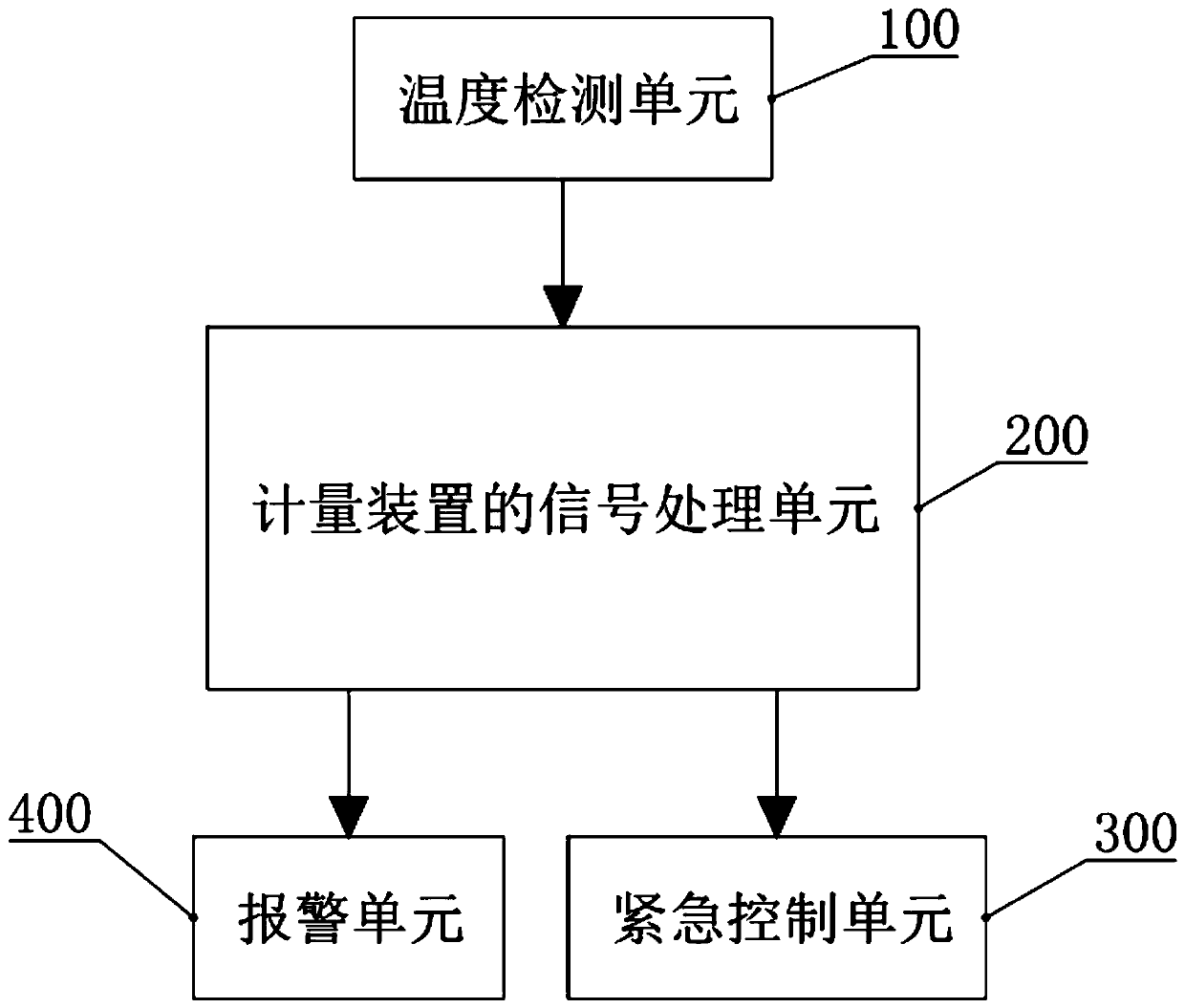

[0024] see figure 1 , in an embodiment of the present invention, a safety gas metering device with an over-temperature cut-off function, comprising:

[0025] The temperature detection unit 100 is used to detect the temperature of the gas environment at the user end, and when the temperature of the gas environment exceeds the limit, a gas valve switch signal is sent to the signal processing unit 200;

[0026] The signal processing unit 200 is used to receive the gas valve switch signal fed back by the temperature detection unit 100 when the gas ambient temperature exceeds the limit, and perform calculation and processing according to the externally detected data, and control the gas valve on and off and data reporting;

[0027] The emergency control unit 300 communicates with the signal processing unit 200 and is used to control the on and off of the gas valve; and

[0028] The alarm unit 400 communicates with the signal processing unit 200 and is used to report to the data ce...

Embodiment 2

[0030] see figure 1 , the difference between this embodiment and embodiment 1 is:

[0031] In this embodiment, the temperature detection unit 100 includes a temperature control switch, and the way to obtain the abnormal temperature of the user's gas environment is through the temperature control switch. When the temperature of the gas environment exceeds the limit, the gas valve switch signal is directly sent to the signal In the processing unit 200, the signal processing unit 200 sends a gas valve cut-off command to realize the emergency cut-off function.

[0032] In this embodiment, the signal processing unit 200 includes an electronic metering device, and the gas valve is set in the electronic metering device, and the abnormal temperature signal of the gas environment at the user end is integrated with the electronic metering device. On the premise of ensuring normal metering Realize the cut-off and alarm for the abnormal temperature of the gas environment at the user end....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com