Spiral load brake

A brake and screw technology, applied in the direction of brake type, automatic brake, mechanical equipment, etc., can solve the problems of large volume, high friction noise, complex structure, etc., and achieve the effect of overcoming the large volume, improving the service life, and overcoming the inconvenience of operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

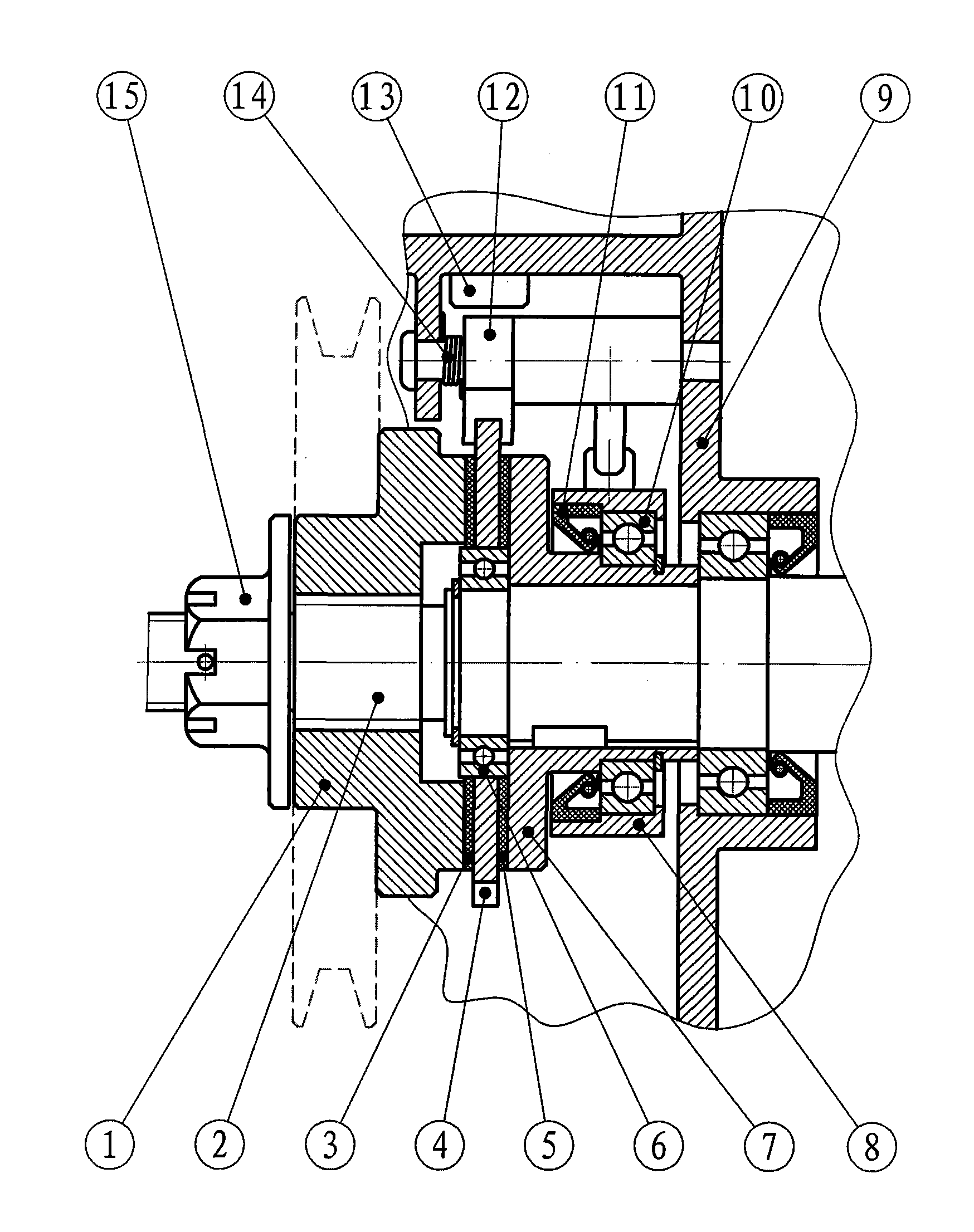

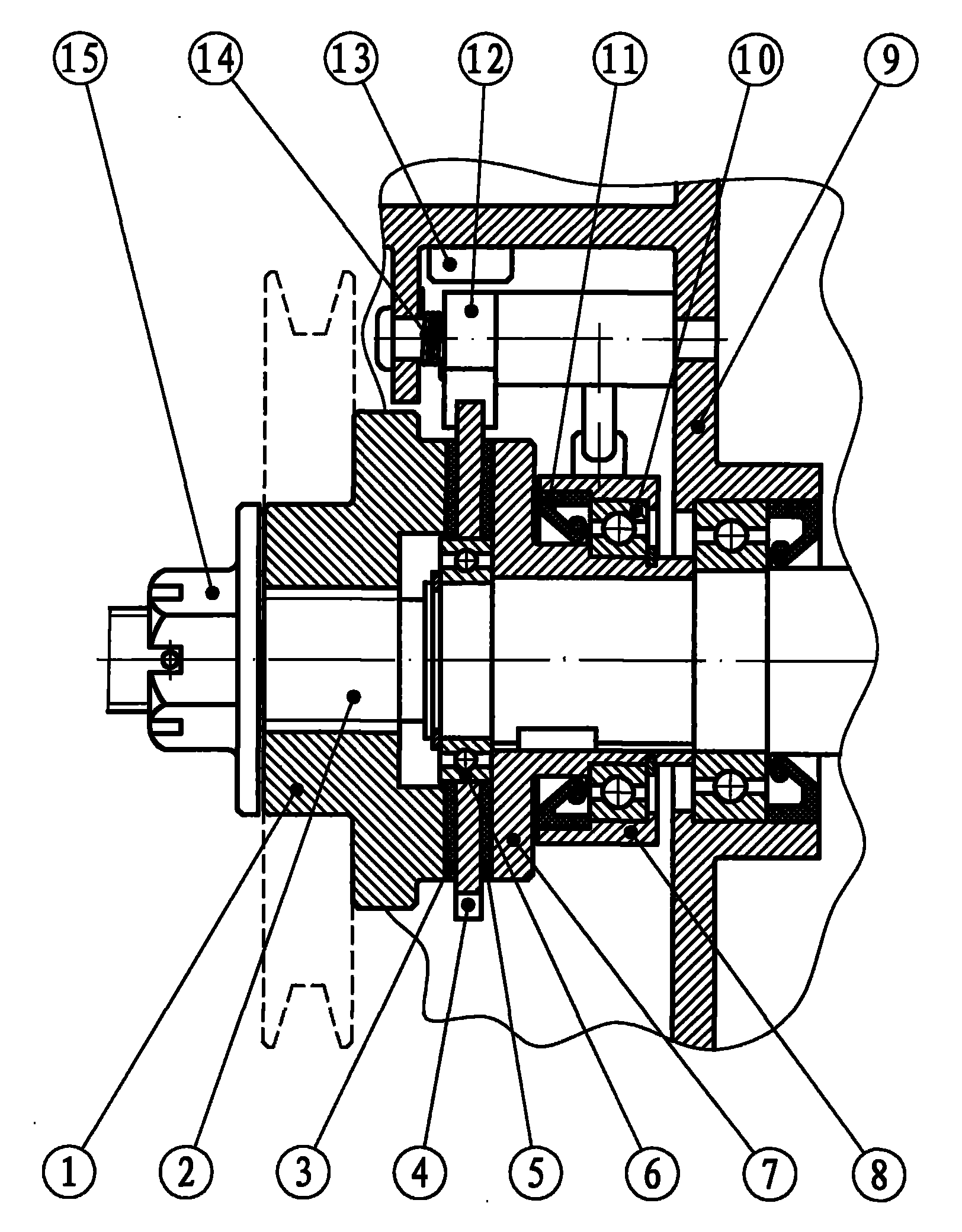

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016]When the heavy object is lifted during the lifting work, the power drives the active friction disc 1 to rotate forward through the transmission wheel (the steering of the active friction disc 1 is set to forward rotation when the weight rises), and the active friction disc 1 moves axially and compresses instantly. Friction plate 3, ratchet 4, friction plate 5, driven friction disc 7, the pressing force is related to the size of the load, the greater the load, the greater the pressing force, the active friction disc 1 and friction plate 3, ratchet 4 , friction plate 5, driven friction disc 7, transmission shaft 2 are locked together and relatively static. At the same time, the dial 8 rotates with the transmission shaft 2 and the driven friction disc 7. Under the action of the friction force generated by the resistance ring 11, the ratchet 12 is dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com