Fuel pump structure

A fuel pump and fuel technology, which is used in liquid fuel feeders, charging systems, engine components, etc., can solve the problems of expensive maintenance costs and difficult maintenance, and achieve the effect of reducing installation and compact installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

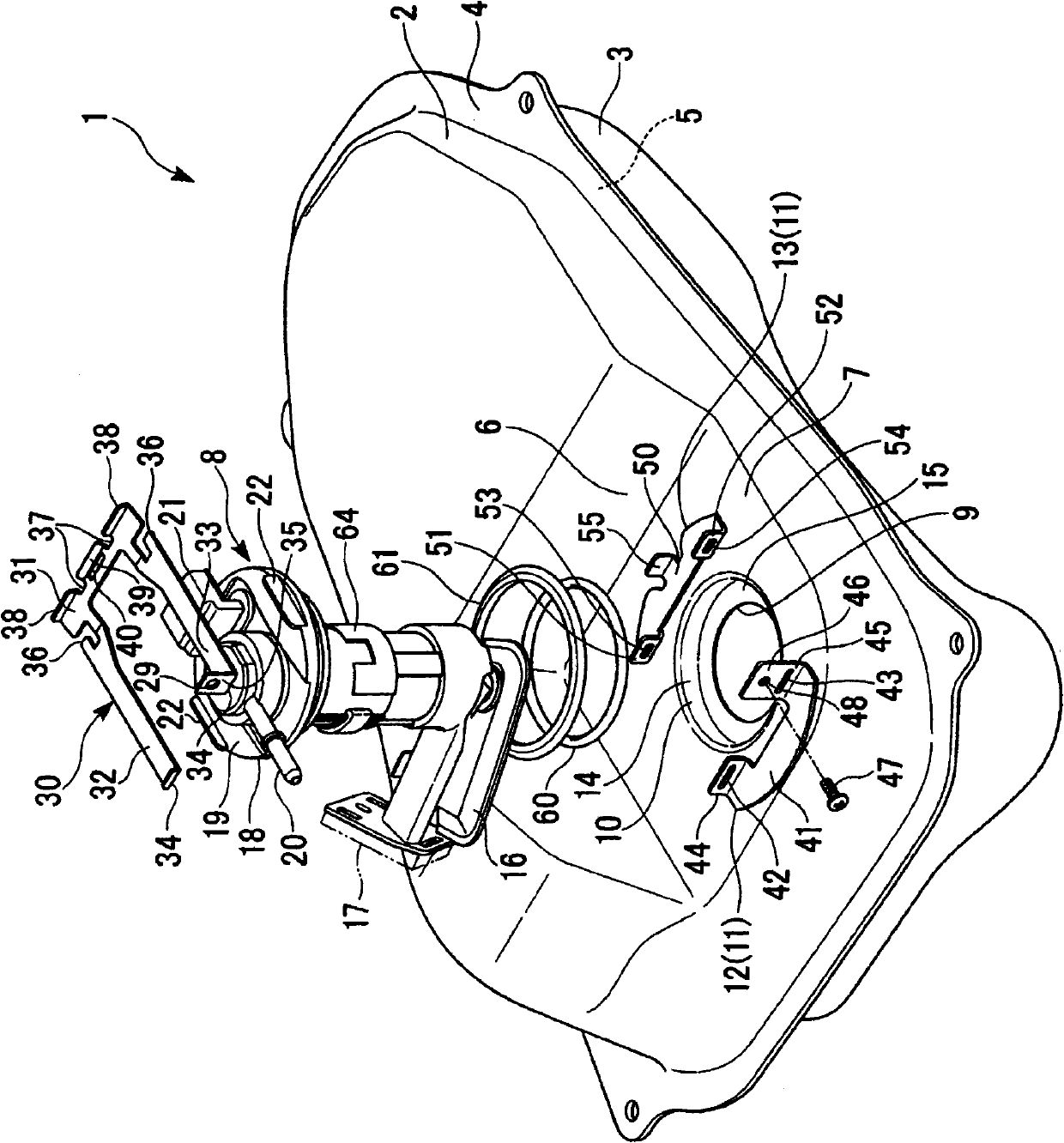

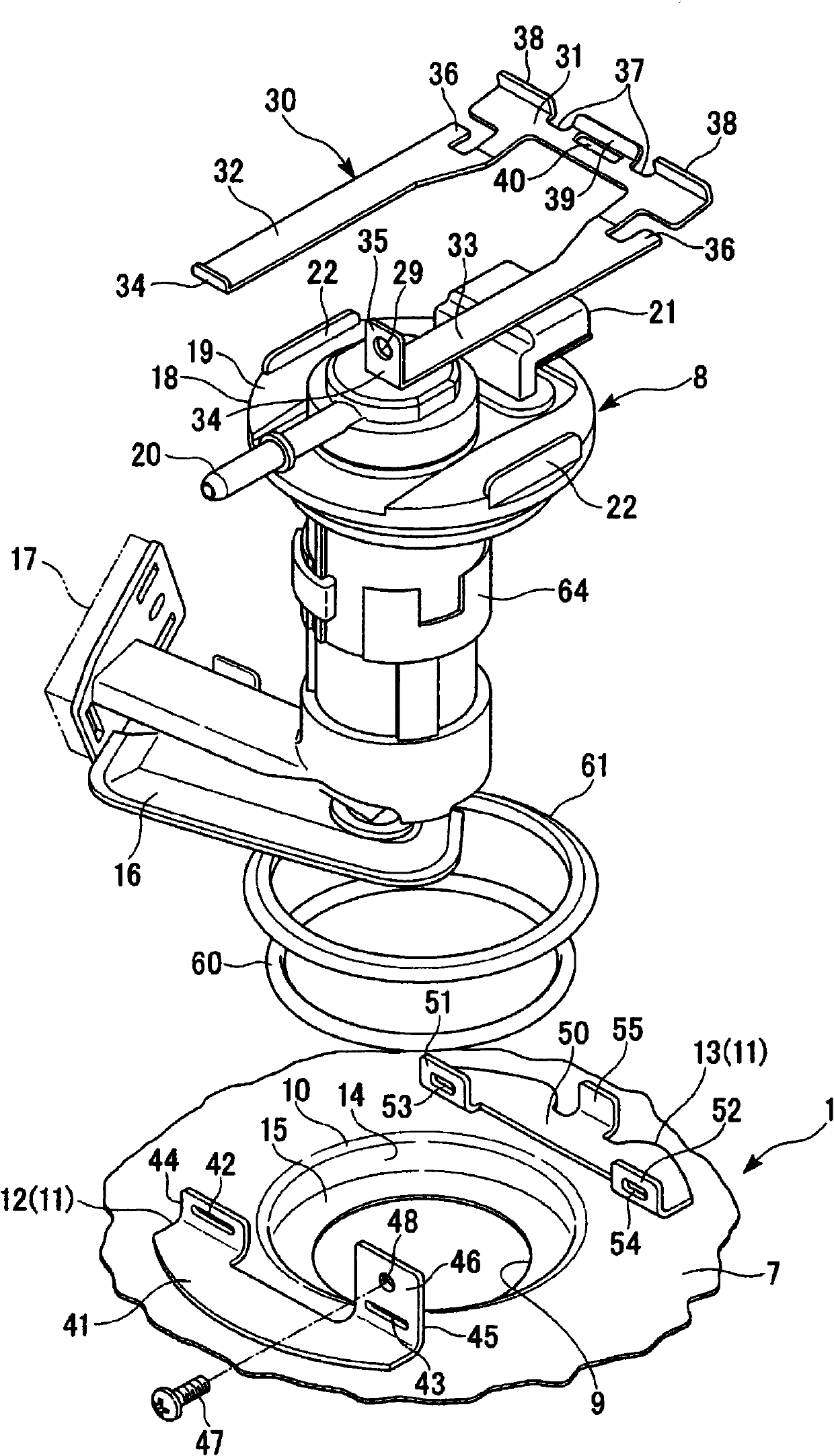

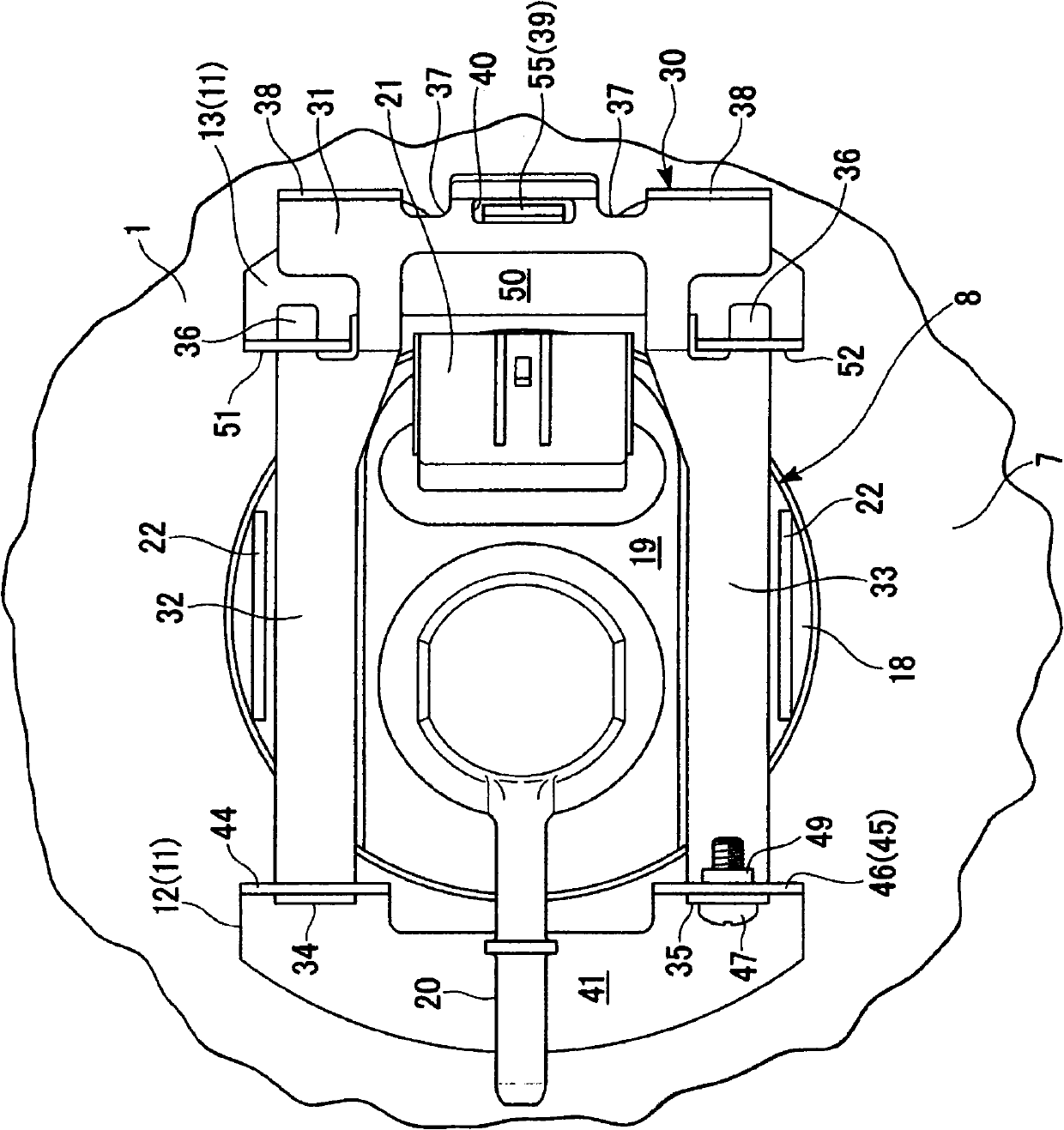

[0078] Below, according to Figure 1 to Figure 6 A first embodiment of the present invention will be described.

[0079] For example, if figure 1 In the shown fuel tank 1 of a motorcycle, an upper half 2 and a lower half 3 made of steel plates are welded to the fuel tank 1 by means of an upper flange 4 and a lower flange 5 . A recess 6 is formed in the upper half 2 , and a flat upper wall 7 is formed in the recess 6 .

[0080] like Figure 1 to Figure 3 As shown, a circular insertion port 9 into which a fuel pump 8 is inserted is formed in the upper wall 7 . The insertion port 9 is formed at a position one step downward from the upper wall 7 via the stepped portion 10 . Around the insertion port 9, an engagement bracket 11 for locking a shutter 30 described later is welded and fixed. Specifically, the engaging bracket 11 is composed of an insertion seat 12 for receiving the bracket 30 and a fixing seat 13 for locking the baffle 30 , and the insertion seat 12 and the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com