Vehicle exhaust heat recovery system and method of managing exhaust heat

A technology for waste heat recovery and vehicles, which is applied to vehicle components, engine starting, engine lubrication, etc., and can solve problems affecting fuel economy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

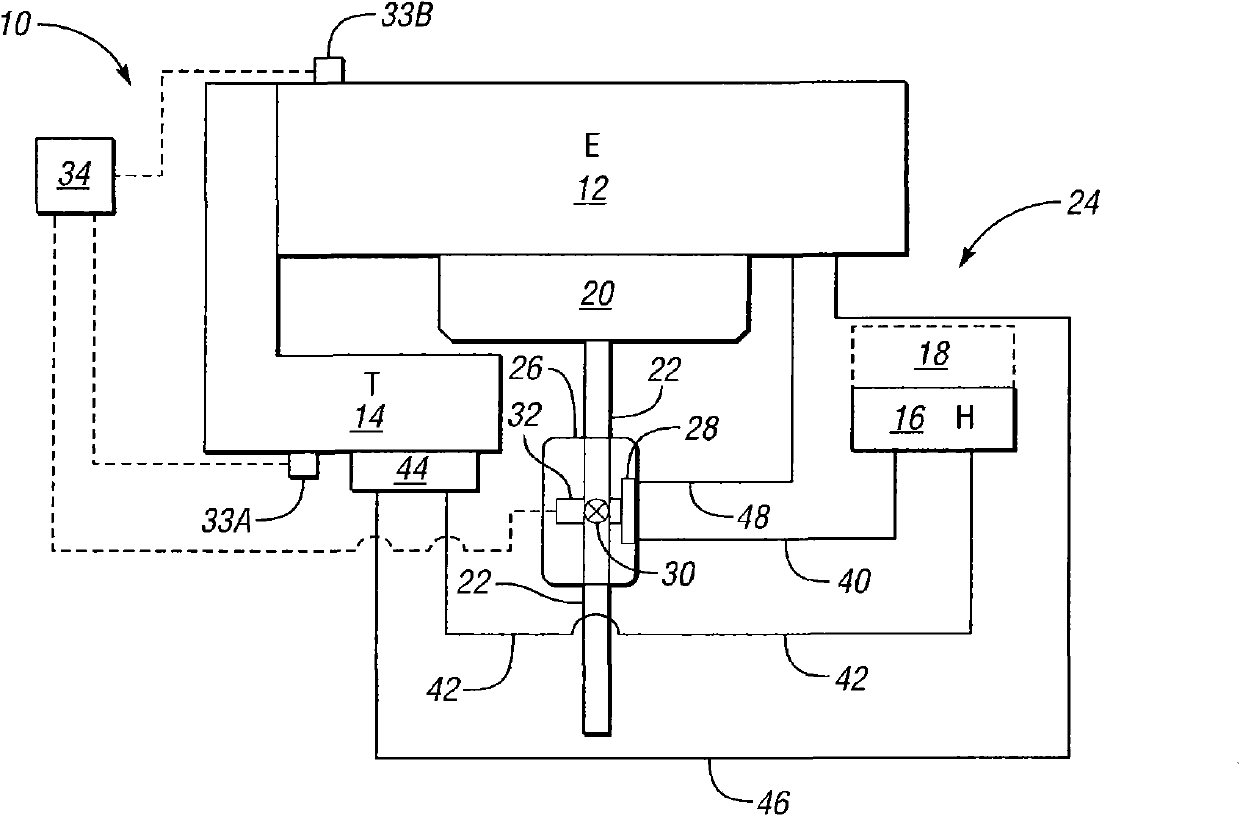

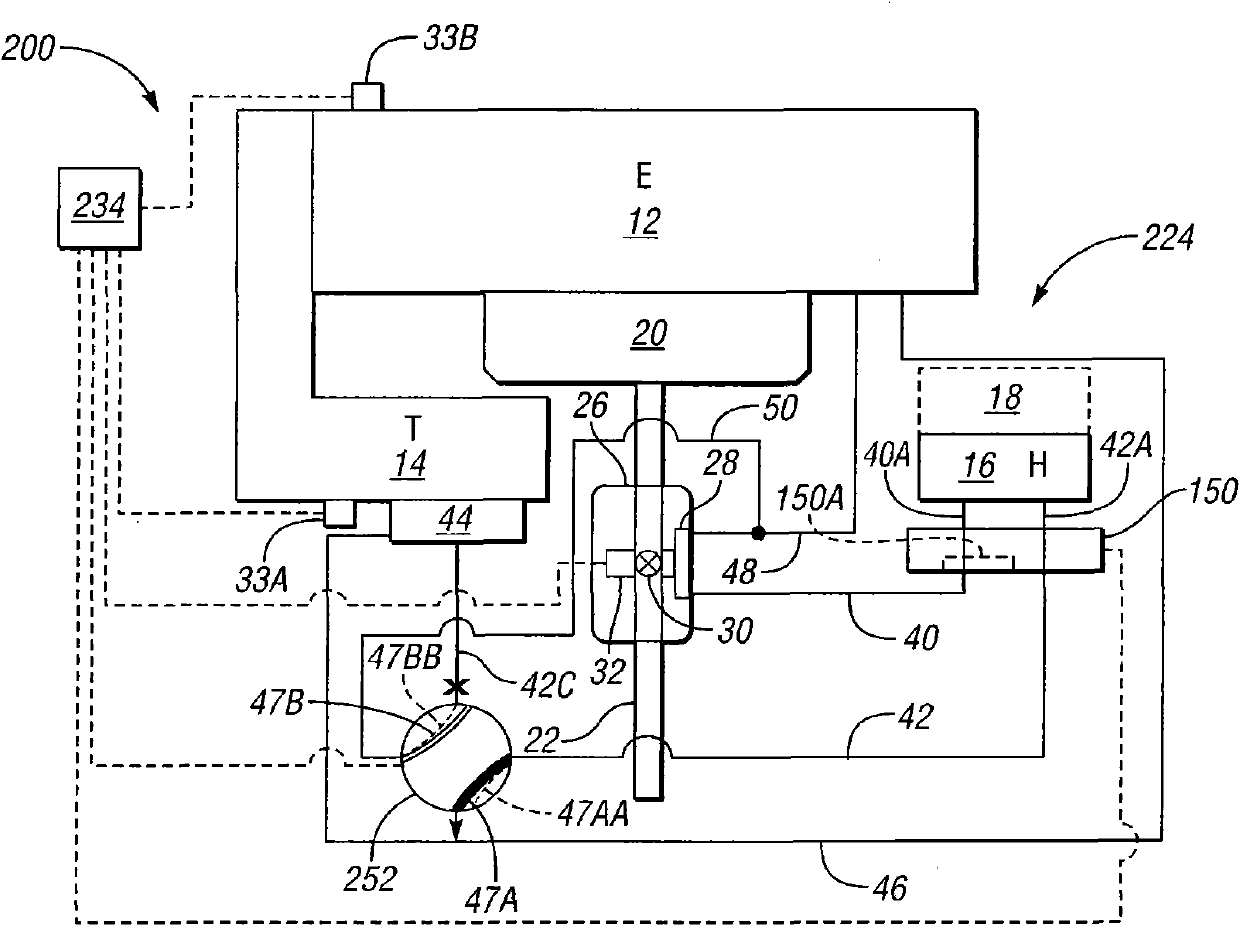

[0052] Referring to the drawings, wherein like reference numerals refer to like parts throughout the several views, figure 1 A vehicle 10 is shown having an engine 12 (labeled E) for propelling the vehicle 10, a transmission 14 (labeled T) operatively connected to the engine 12, and a transmission 14 (labeled T) for heating the passenger compartment (shown in dashed lines at 18 Shown) passenger compartment heater 16 (marked as H).

[0053] Engine 10 is an internal combustion engine of the gasoline or diesel type and produces exhaust gases in an exhaust system including an exhaust manifold 20 and an exhaust pipe 22 extending therefrom. The relatively hot exhaust gases exit the vehicle via exhaust pipe 22 . An exhaust heat recovery system (EHRS) 24 is provided to selectively capture a portion of the waste heat to provide heat to the passenger compartment 16 , transmission 14 , and engine 12 . The EHRS 24 includes an exhaust heat recovery device (EHRD) 26 located within the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com