Continuous ion exchange device and method for extracting lithium from salt lake brine

A salt lake brine and continuous ion technology, applied in the field of continuous ion exchange for extracting lithium and continuous ion exchange device for extracting lithium, can solve the problems of low product concentration, low resin utilization rate, large water consumption, etc., and achieve high concentration of qualified liquid, The effect of high utilization rate and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

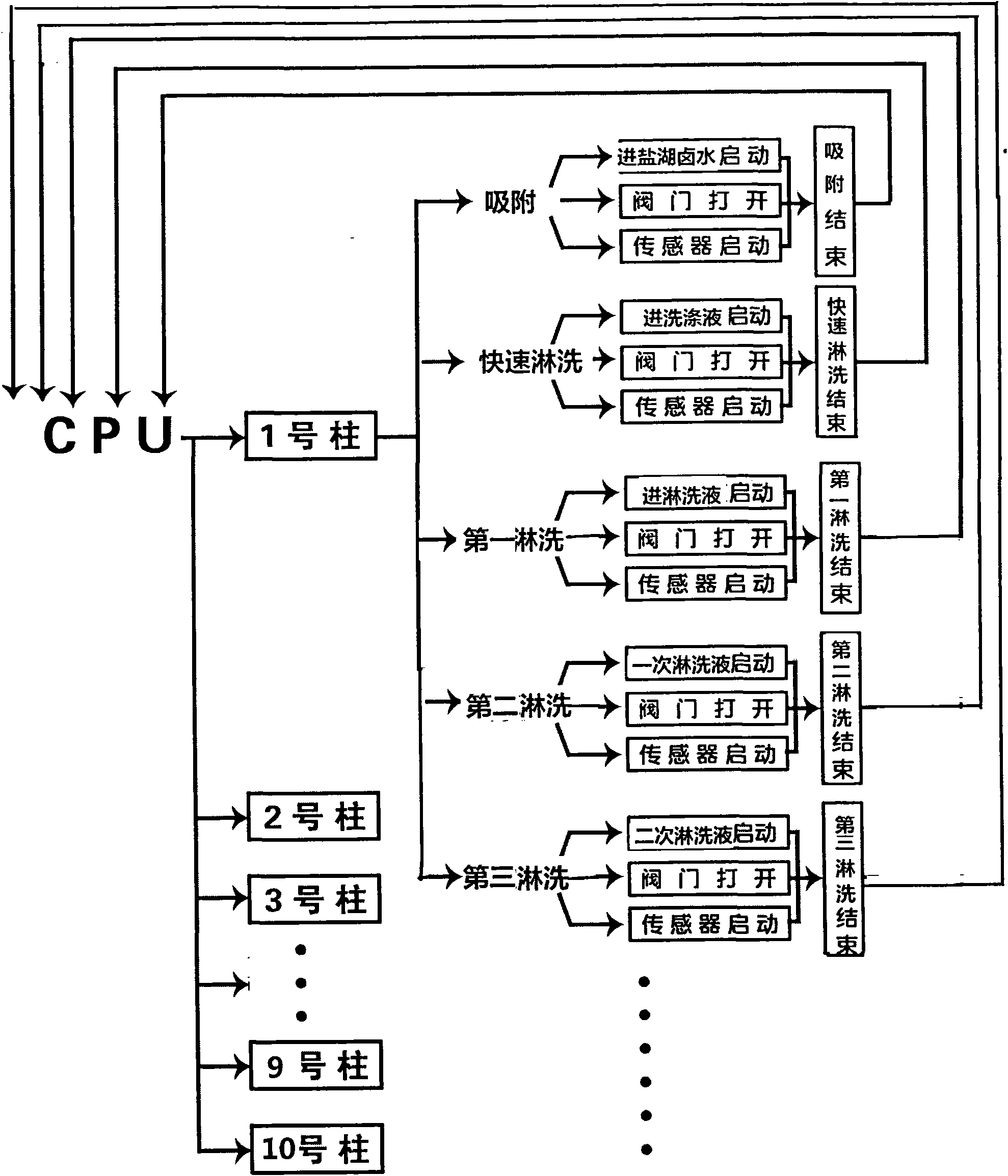

[0076] figure 1 , 2 The number of rinsing resin column groups set in is 3 groups, which are respectively the first rinsing resin column group, the second rinsing resin column group and the third rinsing resin column group, and the upper port of each resin column is provided with The brine feed branch pipe, the fast rinsing feed branch pipe, the washing feed branch pipe, the first reflux feed branch pipe and the second reflux feed branch pipe connected to it, and the brine discharge branch pipe connected to the lower port of each resin column , fast leaching discharge branch pipe, first reflux discharge branch pipe, second reflux discharge branch pipe and qualified liquid discharge branch pipe; the main feed pipe includes brine feed main pipe, fast leaching feed main pipe, washing feed feed main pipe , the first reflux feed main pipe and the second reflux feed main pipe, the discharge main pipe includes the brine discharge main pipe, the fast rinsing discharge main pipe, the f...

Embodiment 2

[0102] The difference with embodiment 1 is:

[0103] The resin of the resin column adopts the ion sieve type adsorbent seplite LXL-10B (Xi’an Lanxiao Technology Co., Ltd.), the content ratio of magnesium and lithium in the initial salt lake brine is 432:1, and the treatment rate of the salt lake brine in the adsorption resin column group of the salt lake brine is 5BV / h, processing capacity: 40BV, the processing rate of deionized water in the fast elution resin column group is 10BV / h, and the processing capacity is 2BV; the first elution resin column group, the second elution resin column group and the third elution resin column group The processing rate of the washing liquid in the eluting resin column group is 3BV / h, and the processing volume is 2BV.

[0104] Among them, the time for the control valve cycle switching is 480min.

[0105] The mass concentration ratio of magnesium and lithium in the upper feed liquid of the second leaching resin column group is 12: 1, and the m...

Embodiment 3

[0107] The difference with embodiment 1 is:

[0108] The resin of the resin column adopts Amberlite IR-120B (Rohm and Haas in the United States), and the magnesium-lithium content ratio in the initial salt lake brine is 432:1. The treatment rate of the salt lake brine in the adsorption resin column group is 6BV / h, and the treatment capacity is 50BV. The treatment rate of deionized water in the fast rinsing resin column group is 15BV / h, and the processing capacity is 4BV; the washing liquid in the first elution resin column group, the second elution resin column group and the third elution resin column group The processing rate is 4BV / h, and the processing capacity is 6BV.

[0109] Among them, the time for the control valve to switch periodically is 500min.

[0110] The mass concentration ratio of magnesium and lithium in the upper feed liquid of the second leaching resin column group is 13.5: 1, and the magnesium and lithium mass concentration ratio in its lower discharge liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com