Silicon oxide series high-temperature infrared radiation coating and preparation method thereof

A technology of high-temperature infrared and radiation coatings, applied in coatings and other directions, can solve the problems of heavy pollution and high energy consumption of industrial furnaces, and achieve the effects of improving economic benefits, reducing energy consumption, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

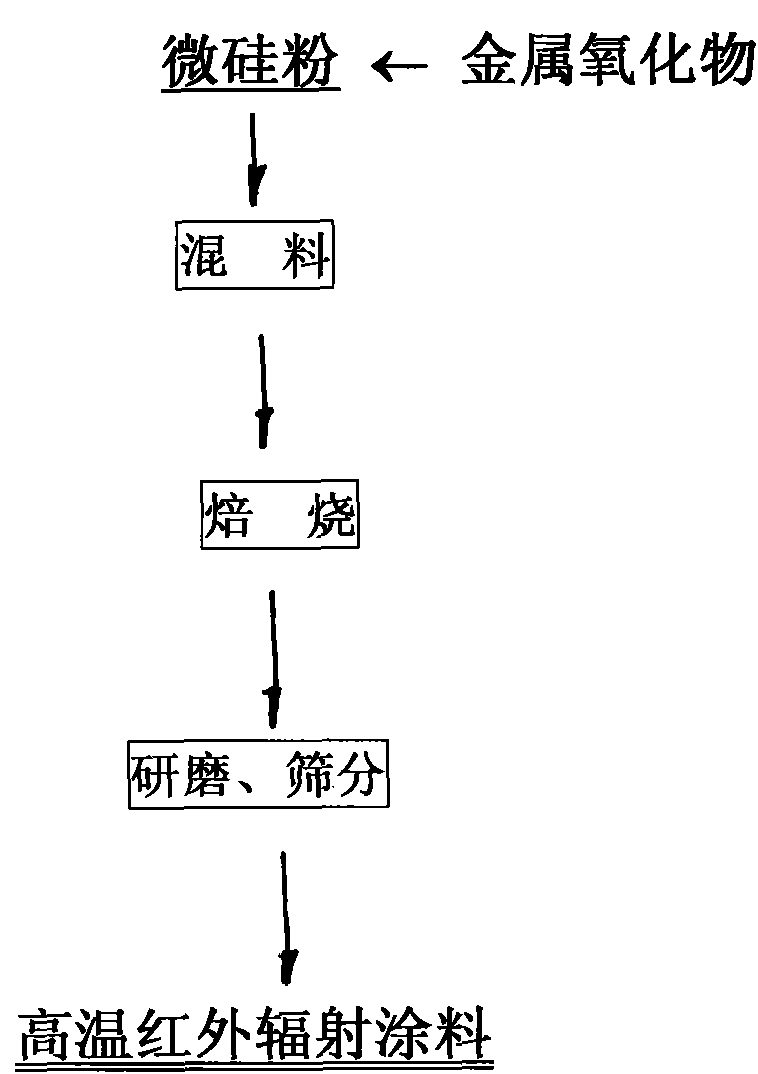

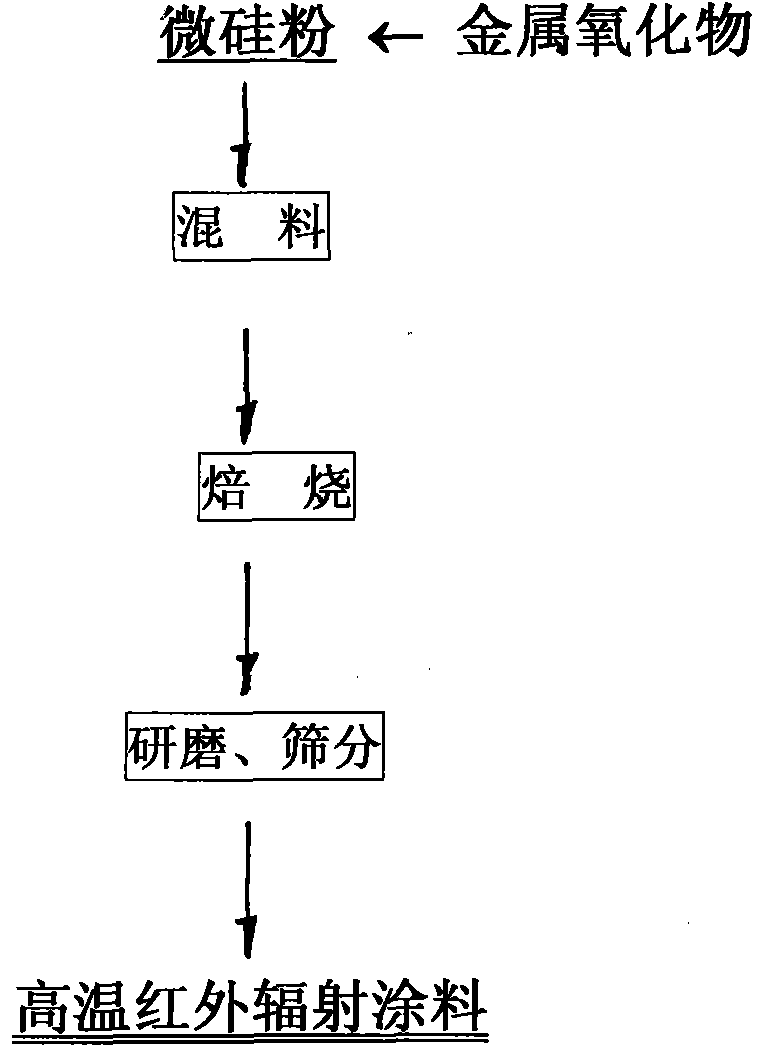

Method used

Image

Examples

Embodiment 1

[0017] Mix the micro-silicon powder obtained from a silicon factory in Yunnan with the designed metal oxide, and its composition is Fe in % by weight 2 o 3 15. Al 2 o 3 20. MgO5, Cr 2 o 3 10. The balance of microsilica fume. The mixed material is sintered at 1200°C for 2 hours at a high temperature, and the powder after grinding and passing through an 80-mesh sieve is the high-temperature infrared radiation coating. The powder is painted on the surface of the refractory material matrix, and its emissivity is 0.90 after testing.

Embodiment 2

[0019] Mix the micro-silicon powder obtained from a silicon factory in Yunnan with the designed metal oxide, and its composition is Fe in % by weight 2 o 3 10. Al 2 o 3 15. MgO5, Cr 2 o 3 10. The balance of microsilica fume. The mixed material is sintered at a high temperature of 1300°C for 1 hour, and the powder after being ground and passed through an 80-mesh sieve is the high-temperature infrared radiation coating. The powder is painted on the surface of the refractory material matrix, and its emissivity is 0.90 after testing.

Embodiment 3

[0021] Mix the micro-silicon powder obtained from a silicon factory in Yunnan with the designed metal oxide, and its composition is Fe in % by weight 2 o 3 10. Al 2 o 3 10. MgO10, Cr 2 o 3 5. The balance of microsilica fume. The mixed material is sintered at a high temperature of 1400°C for 5 hours, and the powder after being ground and passed through an 80-mesh sieve is the high-temperature infrared radiation coating. The powder is painted on the surface of the refractory material matrix, and its emissivity is 0.93 after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com