Plant fiber material composite and preparation method of plant fiber product

A technology of plant fiber material and plant fiber powder, applied in the field of composite materials, can solve the problems of single component, limited decomposition, slow degradation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

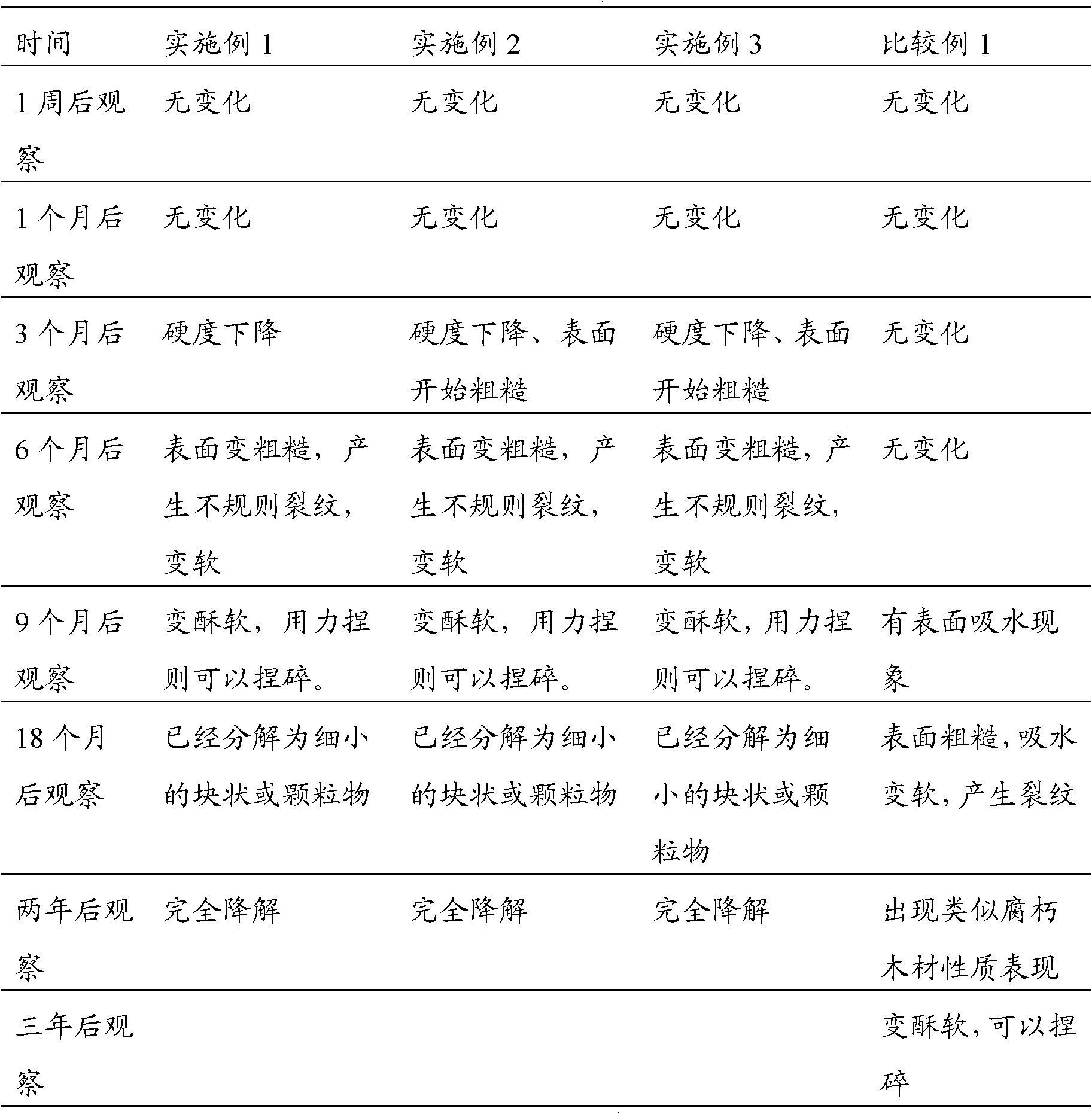

Examples

preparation example Construction

[0034] The present invention also provides a preparation method of plant fiber products, comprising:

[0035] 40wt% to 50wt% of plant fiber powder, 30wt% to 40wt% of soybean protein adhesive, 5wt% to 10wt% of cornstarch, 5wt% to 10wt% of glycerin, 4wt% to 7wt% of rice bran and 3wt% to 8wt% of water is mixed, heated and molded to obtain plant fiber products.

[0036] Plant fiber powder is the main raw material of the plant fiber product, preferably bamboo fiber powder. The content of the plant fiber powder is preferably 42wt%-48wt%, more preferably 43wt%-47wt%. The particle size of the plant fiber powder is preferably 50-80 mesh, more preferably 50-70 mesh.

[0037] Soybean protein adhesive has a bonding effect, which plays the role of bonding various components. The protein component in it can supply microbial protein and other nutrients during the degradation process of plant fiber products, thereby providing more sufficient nutrients for the growth and reproduction of micr...

Embodiment 1

[0050] 50 parts by weight of bamboo powder, 30 parts by weight of soybean protein adhesive, 5 parts by weight of cornstarch and 5 parts by weight of rice bran are fully stirred and mixed evenly in a high-speed mixer, then 5 parts by weight of glycerin and 5 parts by weight of water are added, and the stirring is continued. Adjust the mold temperature of the molding machine to 140°C and the molding pressure to 10Kg / cm 2 ;

[0051] According to the size of the mold, an appropriate amount of mixed raw materials is weighed and poured into the mold, the molding machine is started to heat and mold, and after about two minutes, the mold is demoulded to obtain a plant fiber product.

Embodiment 2

[0053] 45 parts by weight of bamboo powder, 35 parts by weight of soybean protein adhesive, 7 parts by weight of cornstarch, 1 part by weight of Guangdong Zhongshan Huamingtai Chemical Material Co., Ltd. are produced by the model of BS2818 ion modifier and 3 parts by weight of rice bran in Fully stir and mix evenly in a high-speed mixer, then add 5 parts by weight of glycerin and 4 parts by weight of water, continue to stir evenly, adjust the mold temperature of the molding machine to 130°C, and the molding pressure to 12Kg / cm 2 ;

[0054] According to the size of the mold, an appropriate amount of mixed raw materials is weighed and poured into the mold, the molding machine is started to heat and mold, and after about two minutes, the mold is demoulded to obtain a plant fiber product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com