Emulsified asphalt for slab ballastless track

A technology of emulsified asphalt and asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of narrow temperature adaptation range, complex production process, easy layering, etc., and achieves convenient transportation and storage, good storage stability, Early intensity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

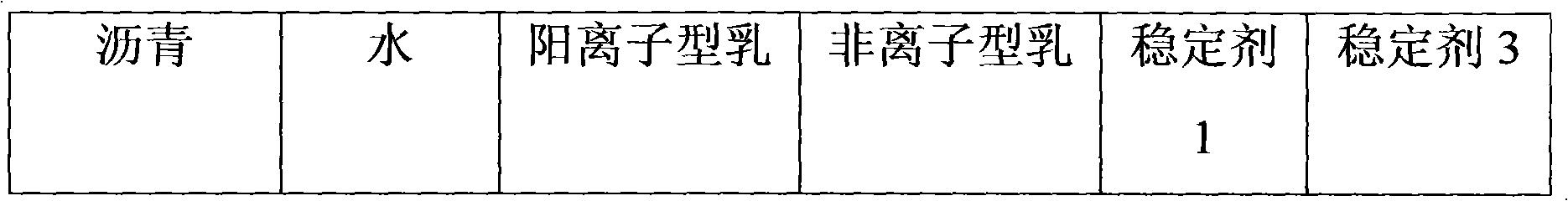

[0031] Carry out proportioning (weight ratio, the same below) with emulsified asphalt raw material according to following (Table 1):

[0032] Table 1 Formula of emulsified asphalt (100 parts of emulsified asphalt)

[0033]

[0034]

[0035] The manufacturing process of emulsified asphalt is as follows:

[0036] A. Dehydrate the asphalt at 110°C-130°C for 1 hour to 2 hours, then heat it gently to 130°C-160°C, and measure it for later use;

[0037] B. Heat the tap water to 45°C-65°C and measure it for later use;

[0038] C. Add the emulsifier and stabilizer to the standby hot water, stir evenly to make an emulsified aqueous solution, control the temperature at 45°C-65°C, and set aside;

[0039] D. Turn on the emulsifier system, pour the emulsified aqueous solution that meets the temperature requirements into the emulsification, and immediately pour in the hot asphalt that meets the temperature requirements, and the emulsified asphalt that meets the requirements is prepar...

Embodiment 2

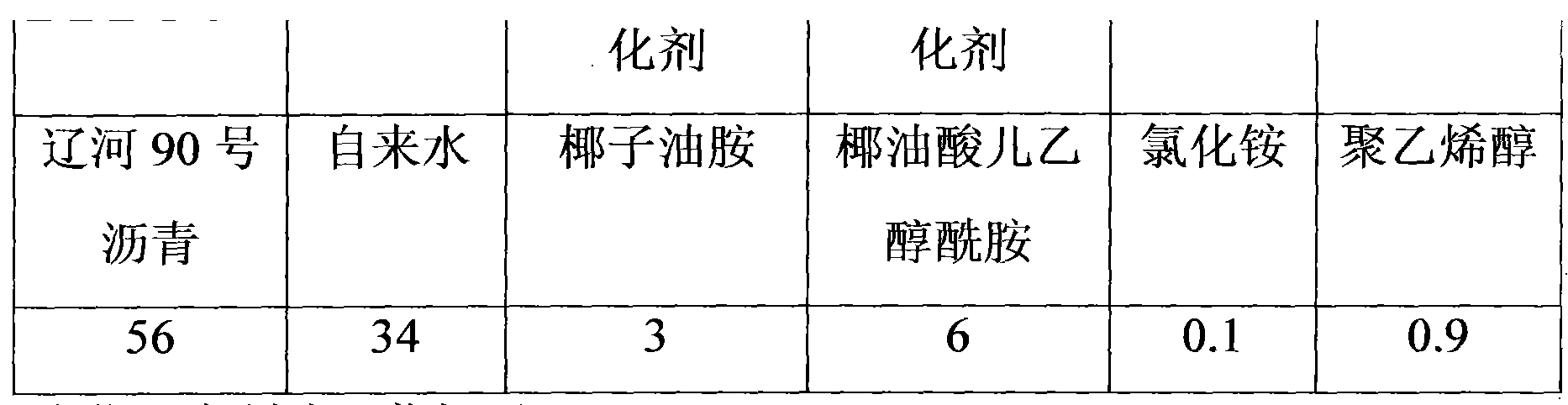

[0041] Carry out proportioning (weight ratio, the same below) with emulsified asphalt raw material according to following (table 2):

[0042] Table 2 Formula of emulsified asphalt (100 parts of emulsified asphalt)

[0043]

[0044] The emulsified asphalt manufacturing process of embodiment 2 is as embodiment 1

Embodiment 3

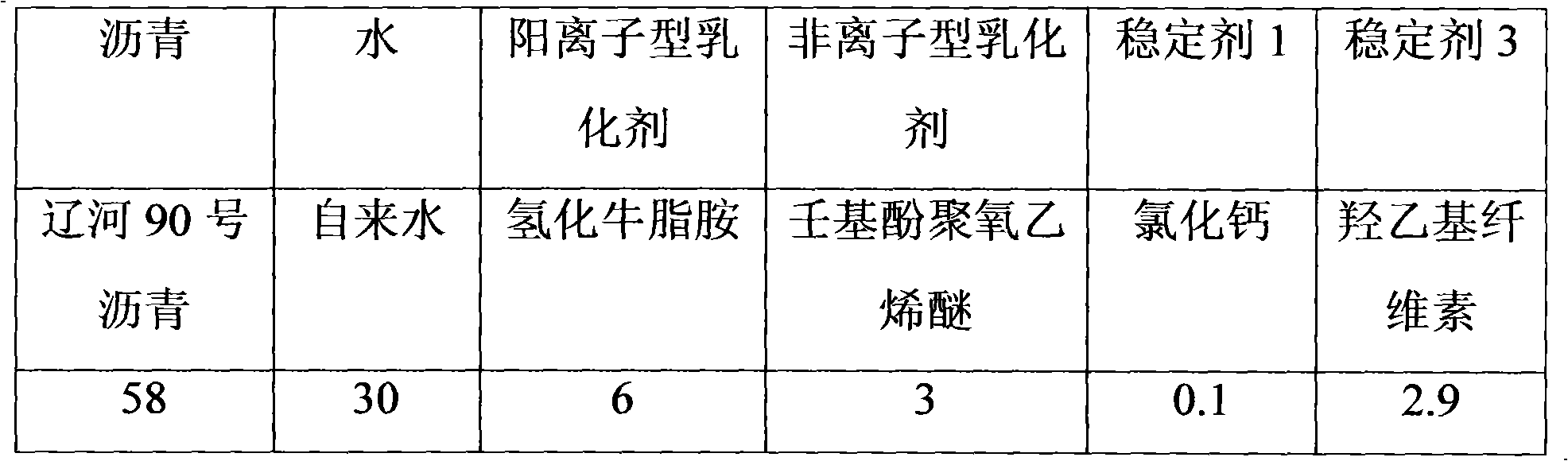

[0046] Carry out proportioning (weight ratio, the same below) with emulsified asphalt raw material according to following (table 3):

[0047] Table 3 Formula table of emulsified asphalt (100 parts of emulsified asphalt)

[0048]

[0049] The emulsified asphalt manufacturing process of embodiment 3 is as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com