Chain magazine

A chain tool magazine and chain link technology, which is applied in the manufacture of tools, transportation and packaging, metal processing machinery parts, etc., can solve the problems of high labor and cost, heavy load, etc., and achieve the effect of simplifying manufacturing and reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

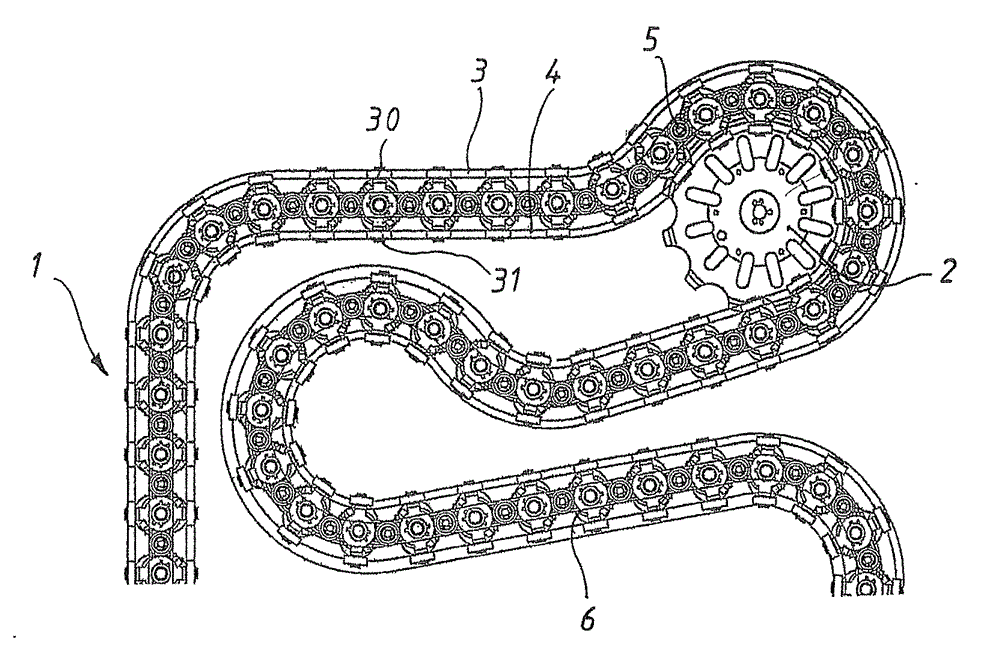

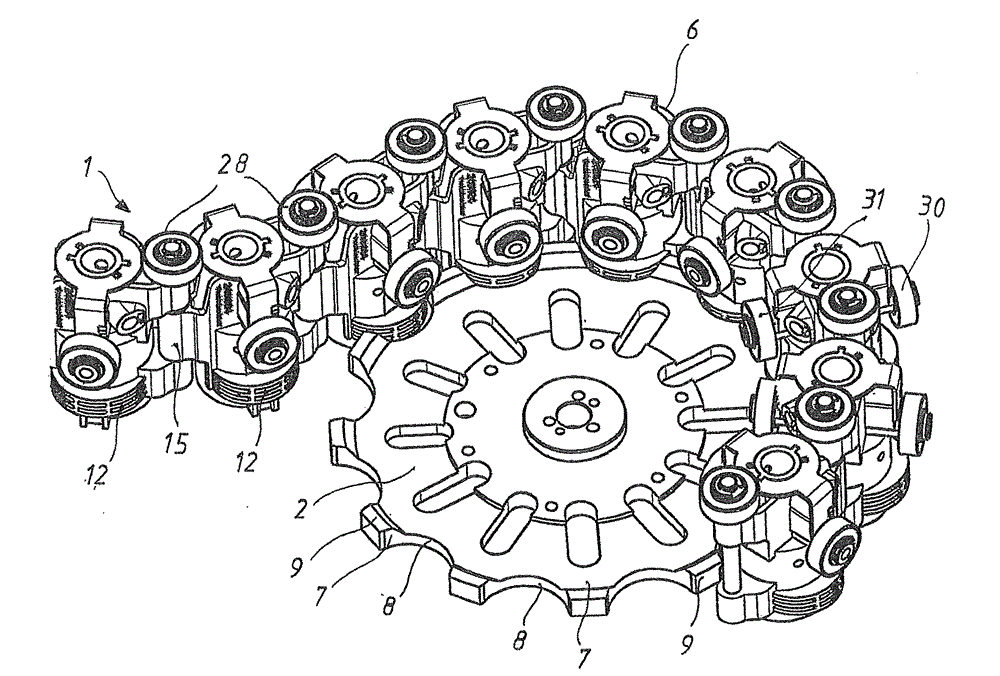

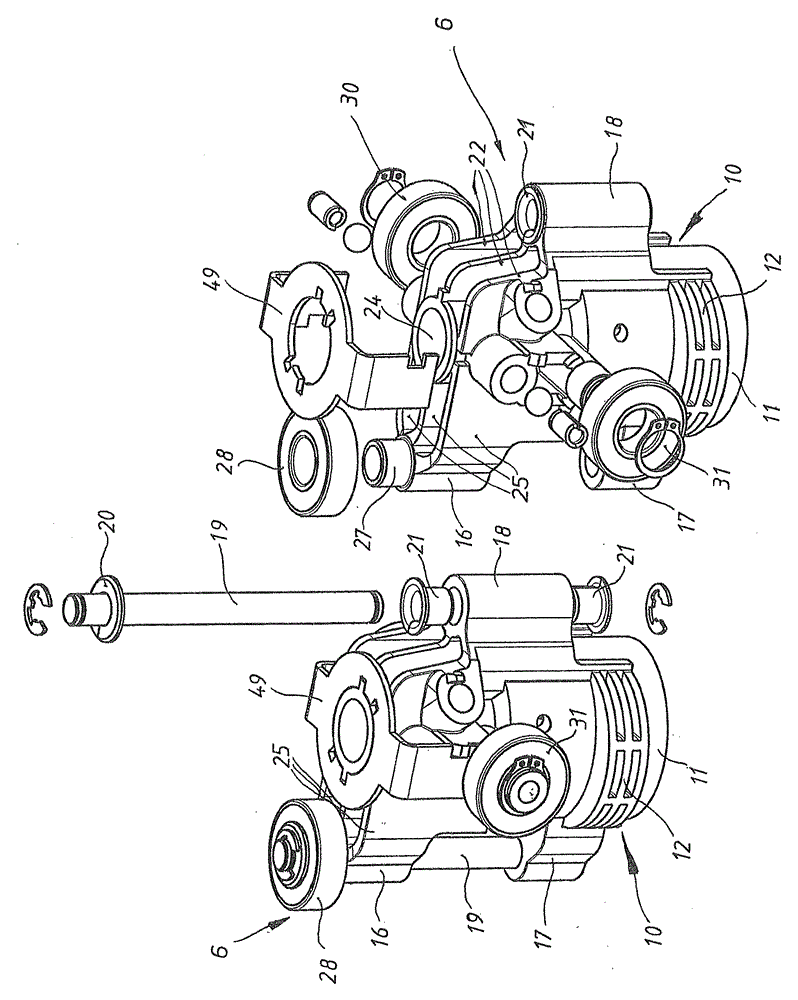

[0020] figure 1 A schematic top plan view showing only a part of the chain magazine of the invention. In this embodiment the meander-guided tool chain 1 moves on a support structure (not shown) to which a drive pulley 2 and a diverting pulley (not shown) are mounted. In addition, the two side rails 3 , 4 and the central rail 5 for the tool chain 1 are arranged on the support structure as guide elements. The knife chain 1 consists of a plurality of chain links 6 articulated to each other, which are produced from light metal or from a dimensionally stable and wear-resistant plastic material by suitable molding or injection molding techniques. Such as figure 2 It can be seen in the figure that the transmission pulley 2 has toothed lugs 7 on its outer rim, the pitch between which is determined by the size of the chain link 6 . These toothed lugs 7 are spaced apart in the circumferential direction by ring-segment-shaped recesses 8 and have thickened end portions 9 intended to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com