Transport refrigeration system and method of operation

A refrigerant and compression system technology, applied in refrigerators, refrigeration components, transportation and packaging, etc., can solve problems such as low mass flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

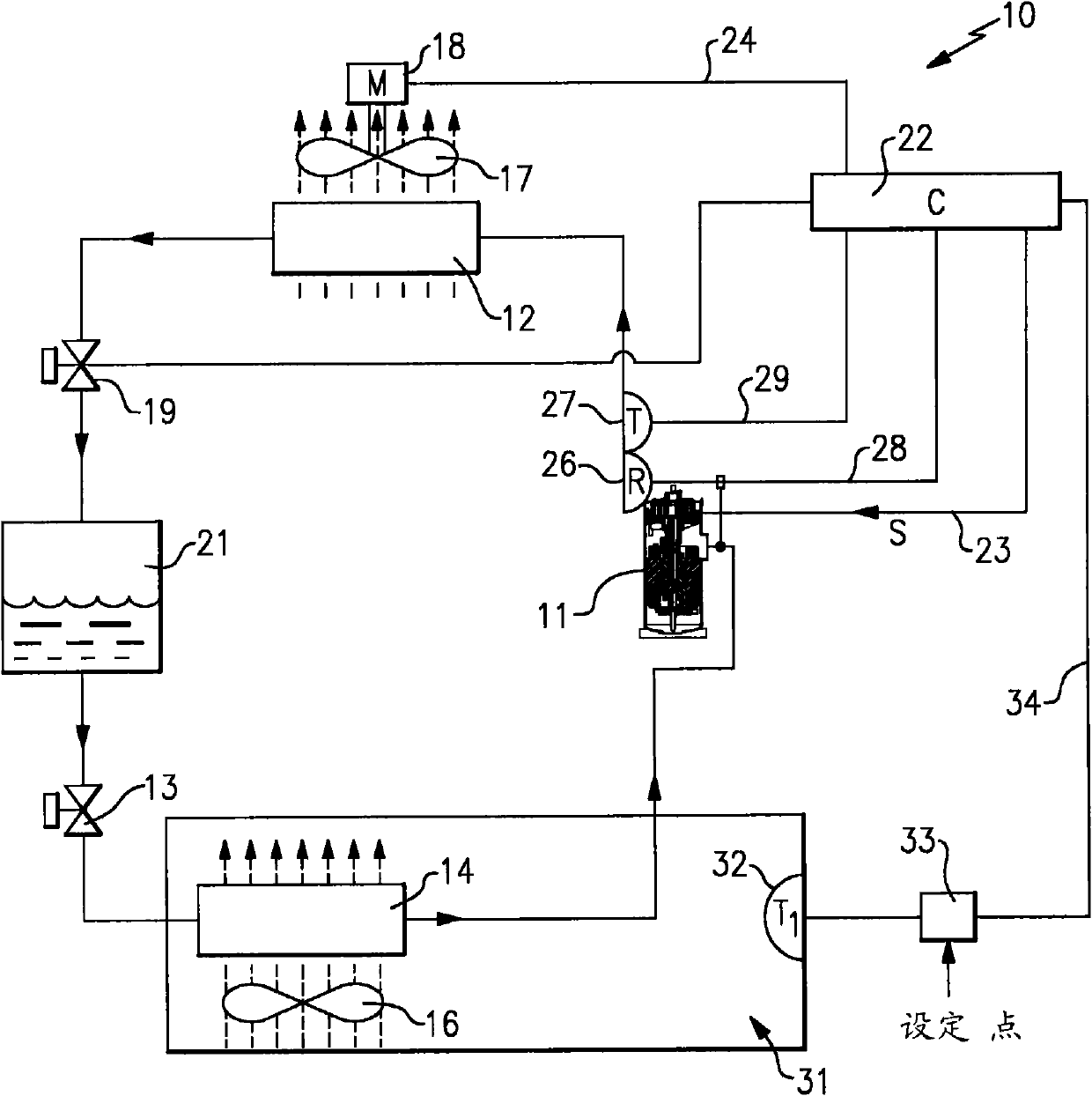

[0015] The present invention, shown generally at 10, is incorporated into a refrigerant vapor compression system utilizing CO 2 Operating as a refrigerant and comprising a compressor 11 , a refrigerant heat sink heat exchanger 12 , an expansion device 13 and a refrigerant heat sink heat exchanger 14 in series flow relationship. A refrigerant absorption heat exchanger 14, commonly referred to as an evaporator, includes a motor driven fan 16 for circulating air thereover for cooling.

[0016] Since the system uses CO 2 As a working fluid, it must operate in a transcritical cycle such that the high-pressure refrigerant of the refrigerant-radiation heat exchanger 12 (which may be referred to as a condenser) is in contact with the cooling medium (most commonly ambient) in an air conditioning system or transport refrigeration system. Air) is transferred in a heat exchange relationship. In such a refrigerant vapor compression system operating in a transcritical cycle, the refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com