Print head assembly, screen printing system and method

A printing screen, printing head technology, applied in screen printing, screen printing machine, printing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

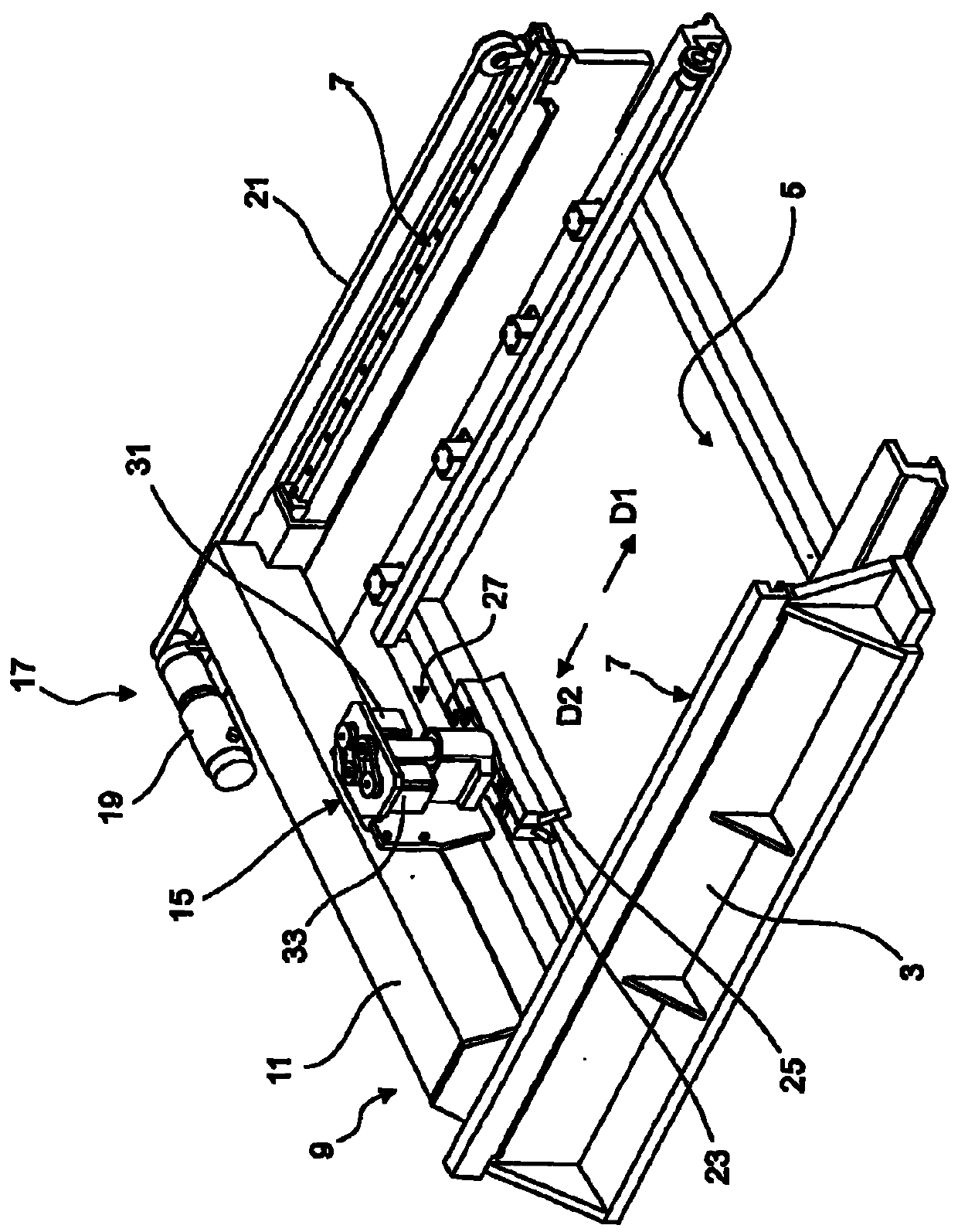

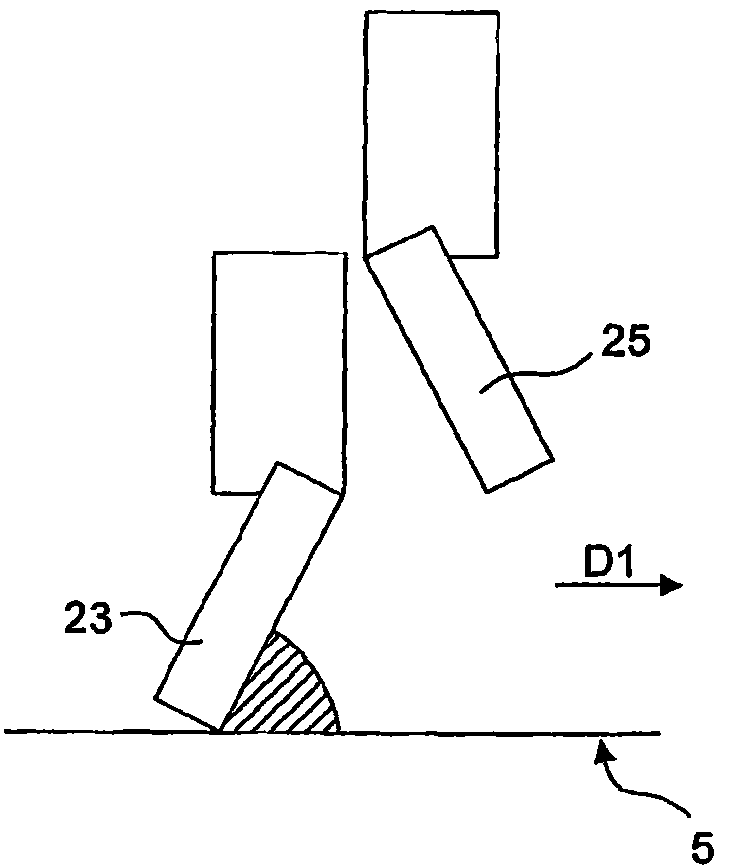

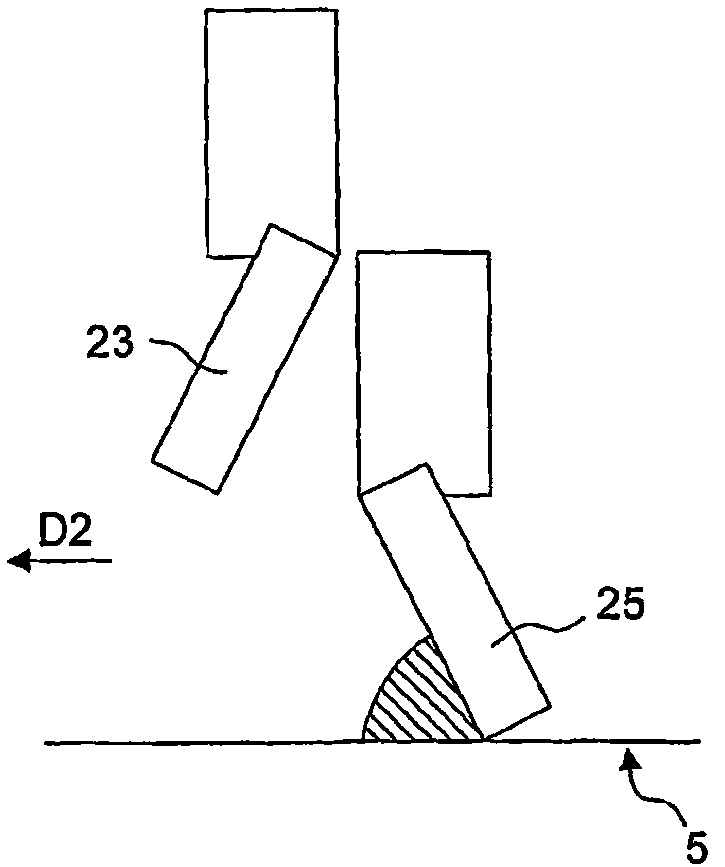

[0121] image 3 6 to 6 illustrate a screen printing system according to a preferred embodiment of the present invention, which is configured to receive a printing screen 105 and to print on a workpiece through the printing screen 105 .

[0122] In this embodiment, the printing screen 105 comprises a rectangular frame 107 in plan view and a screen member 109 mounted in tension on the frame 107 and comprising a pattern 110 of a plurality of printing holes, here the The screen member 109 is in the form of a monolithic sheet of metallic or plastic material, or a coated screen, the pattern defining a printing area through which the printing medium is printed onto a surface supported on the printing screen. on the lower workpiece.

[0123]The screen printing system comprises a rigid support frame 111 supporting the printing screen 105; first and second horizontal guide mechanisms 117, 117 arranged parallel on the support frame 111 at opposite sides of the printing screen 105; asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com