Linear ultrasonic motor based on alternating force and electric excitation method

A linear ultrasonic motor, alternating force technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the tangential alternating force linear ultrasonic motor that has not yet been seen and other problems, to achieve the effect of simple structure, small size and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

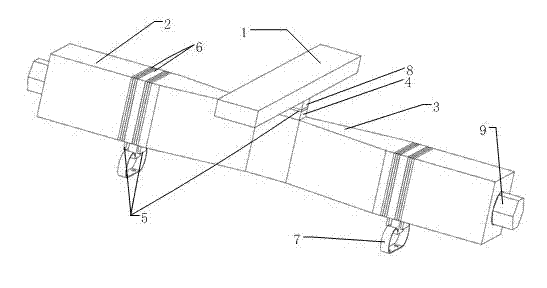

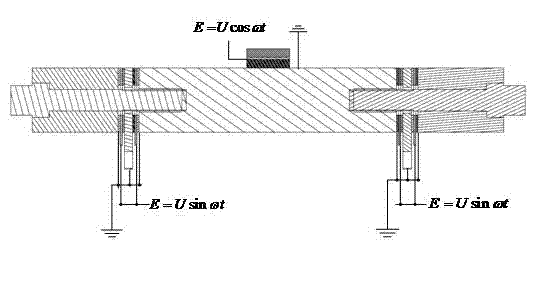

[0018] A linear ultrasonic motor based on alternating force such as figure 1 As shown, it includes the stator and the mover. The stator is mainly composed of two Langevin vibrators on the left and right butt joints along the center line. Each Langevin vibrator consists of a front cover 3, a rear end cover 2, a piezoelectric ceramic sheet 6 and a Composed of electrode sheets 5, and the overall cross-section is a continuous cross-section rod structure that tapers from the tail to the head. The heads of the two Langevin vibrators on the left and right are butted and connected as a whole. In addition, the joints of the two Langevin vibrators are parallel to the A piezoelectric ceramic sheet 4 for driving feet is pasted on the surface of the bending vibration surface of the vibrator, and an electrode sheet 5 and a friction sheet 8 are pasted on the piezoelectric ceramic sheet 4 for driving feet to form a driving foot. The mover is a linear guide rail 1 Arranged in a "cross" shape w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com