Alternating force based linear ultrasonic motor

A linear ultrasonic motor, alternating force technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. and other problems, to achieve the effect of simple structure, small size and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

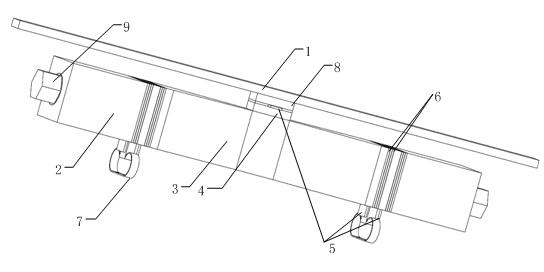

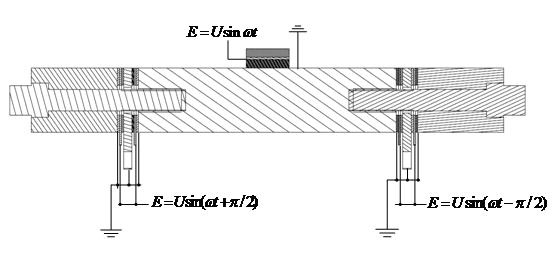

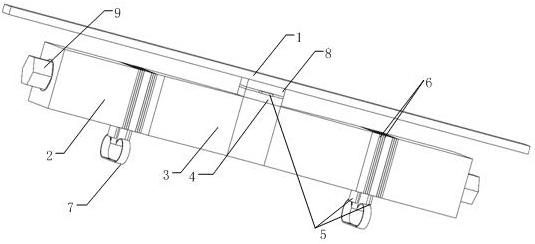

[0018] A linear ultrasonic motor based on alternating force such as figure 1 As shown, it includes a stator and a mover. It is characterized in that: the stator is mainly composed of two left and right Langevin vibrators butted along the center line, and each Langevin vibrator is composed of a front cover 3, a rear end cover 2, a piezoelectric The ceramic sheet 6 and the corresponding electrode sheet 5 are composed of a continuous cross-section rod structure whose section is tapered from the tail to the head as a whole. A piece of piezoelectric ceramic sheet 4 for the driving foot is pasted on the surface parallel to the longitudinal vibration surface of the vibrator at the joint of the vibrator, and an electrode sheet 5 and a piece of friction sheet 8 are pasted on the piezoelectric ceramic sheet 4 for the driving foot to form the driving foot. The mover is A linear guide rail 1 is arranged in a parallel structure with the above-mentioned stator and contacts each other at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com