A fan-shaped linear ultrasonic motor based on the principle of continuous horn

A linear ultrasonic motor and horn technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of low utilization of stator space and achieve structural Simple, clear blessing point, high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

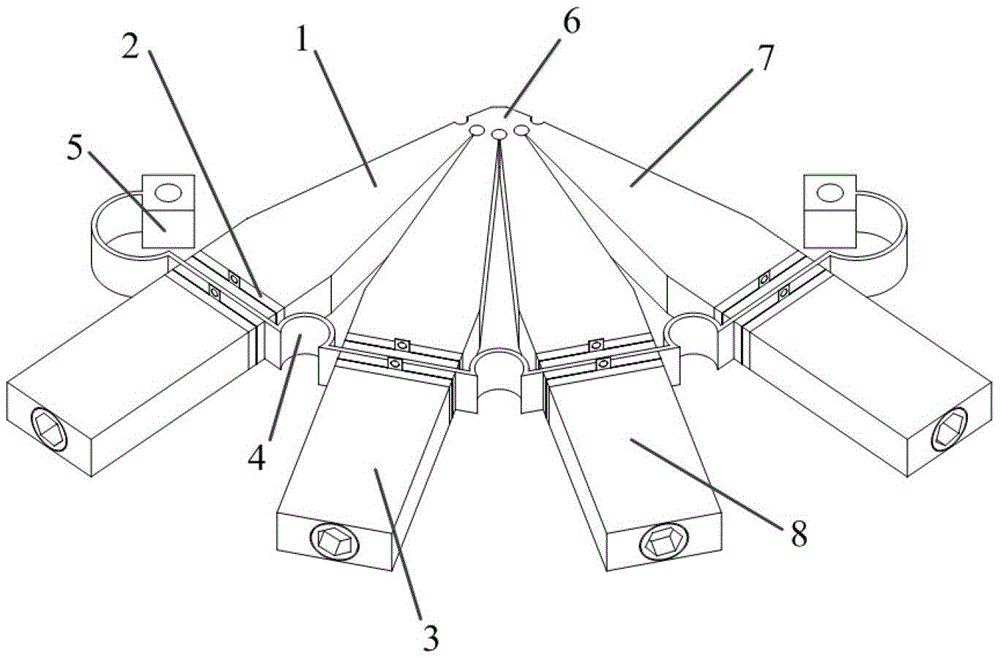

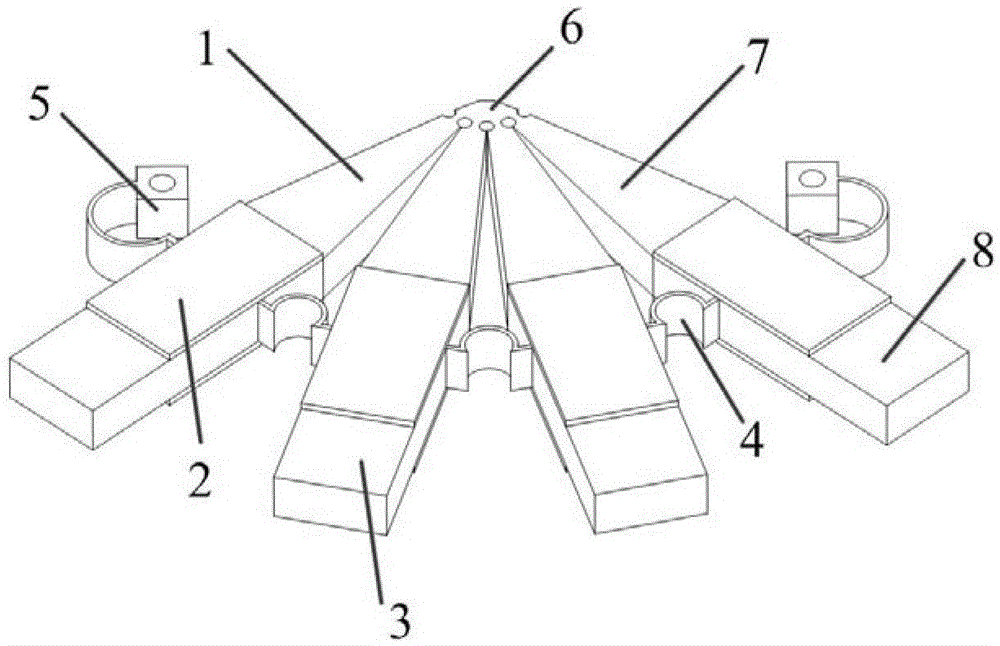

[0022] A fan-shaped linear ultrasonic motor based on the principle of continuous horn in this embodiment is as follows: figure 2 , 4 As shown, the linear ultrasonic motor of this embodiment, because its Langevin vibrator is bonded by the vibrator substrate and the piezoelectric ceramic sheet, it is called a chip-type sector motor, and the stator of the motor is composed of 2n(n> 1) Two Langevin oscillators intersect at a certain angle to form a fan-shaped structure. Considering the principles of simple design and easy processing, four Langevin oscillators are used in the design of this embodiment, and the Langevin oscillators are spaced at the same angle. Open; the Langevin vibrator includes a vibrator base and two piezoelectric ceramic sheets, the vibrator base includes a rear end as a straight rod and a front end as a continuously variable cross-section rod, and the rear end and front end The interface of the vibrator base is a continuous section, the front end is in a sta...

Embodiment 2

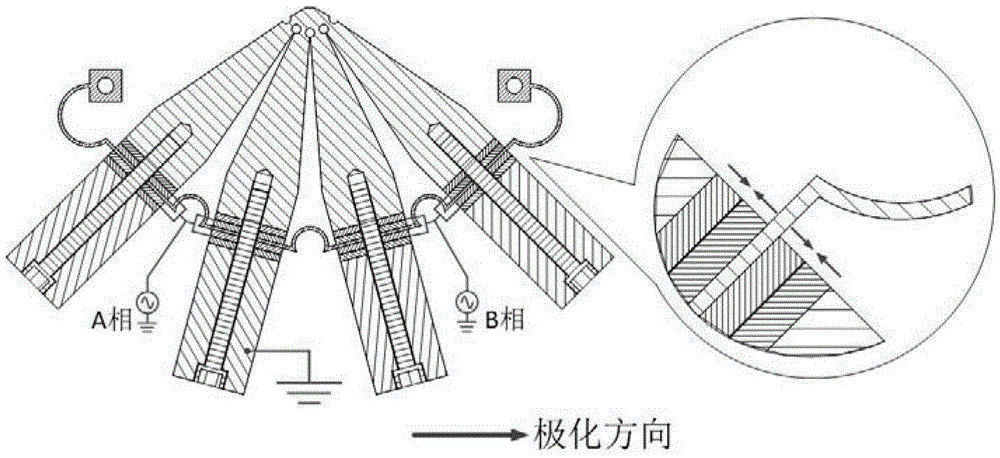

[0028] The excitation signal loading method of this embodiment is the same as that of this embodiment 1, and the difference between this embodiment and embodiment 1 lies in that the piezoelectric ceramic polarization effect on which the operating mechanism of the motor depends is different. Option 1 utilizes piezoceramic d 31 effect, Scheme 2 utilizes piezoelectric ceramic d 33 effect. Therefore, the difference in its structure is: figure 1 ,3 As shown, the Langevin vibrator includes a vibrator base, four piezoelectric ceramic sheets and two electrode metal sheets, and each two piezoelectric ceramic sheets and one electrode metal sheet form a group, respectively placed on the vibrator base. On both sides of the clamping piece, and each electrode metal sheet is sandwiched between two piezoelectric ceramic sheets; the front end of the Langevin vibrator is connected to the electrode metal sheet, piezoelectric ceramic sheet, and flexible clamping piece through bolts It is assem...

Embodiment 3

[0031] The difference between this embodiment and Embodiments 1 and 2 is that the excitation signal loading method of this embodiment is different from that of Embodiments 1 and 2, and its structure adopts the structure of Embodiment 1, such as figure 2 , 4 As shown, the piezoelectric vibrators of the stator are divided into two groups, the two Langevin vibrators on the outside are divided into one group, and the two Langevin vibrators on the inner side are divided into one group. For the two outer Langevin vibrators, the polarization direction of the piezoelectric ceramic sheet of one of the Langevin oscillators is opposite to the polarization direction of the piezoelectric ceramic sheet of the other Langevin oscillator. Simultaneously excite the two outer Langevin vibrators with the same sinusoidal signal, so that the mass point on the driving foot makes horizontal reciprocating motion. Use a certain phase difference with the above sinusoidal signal ( ) The other sinusoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com