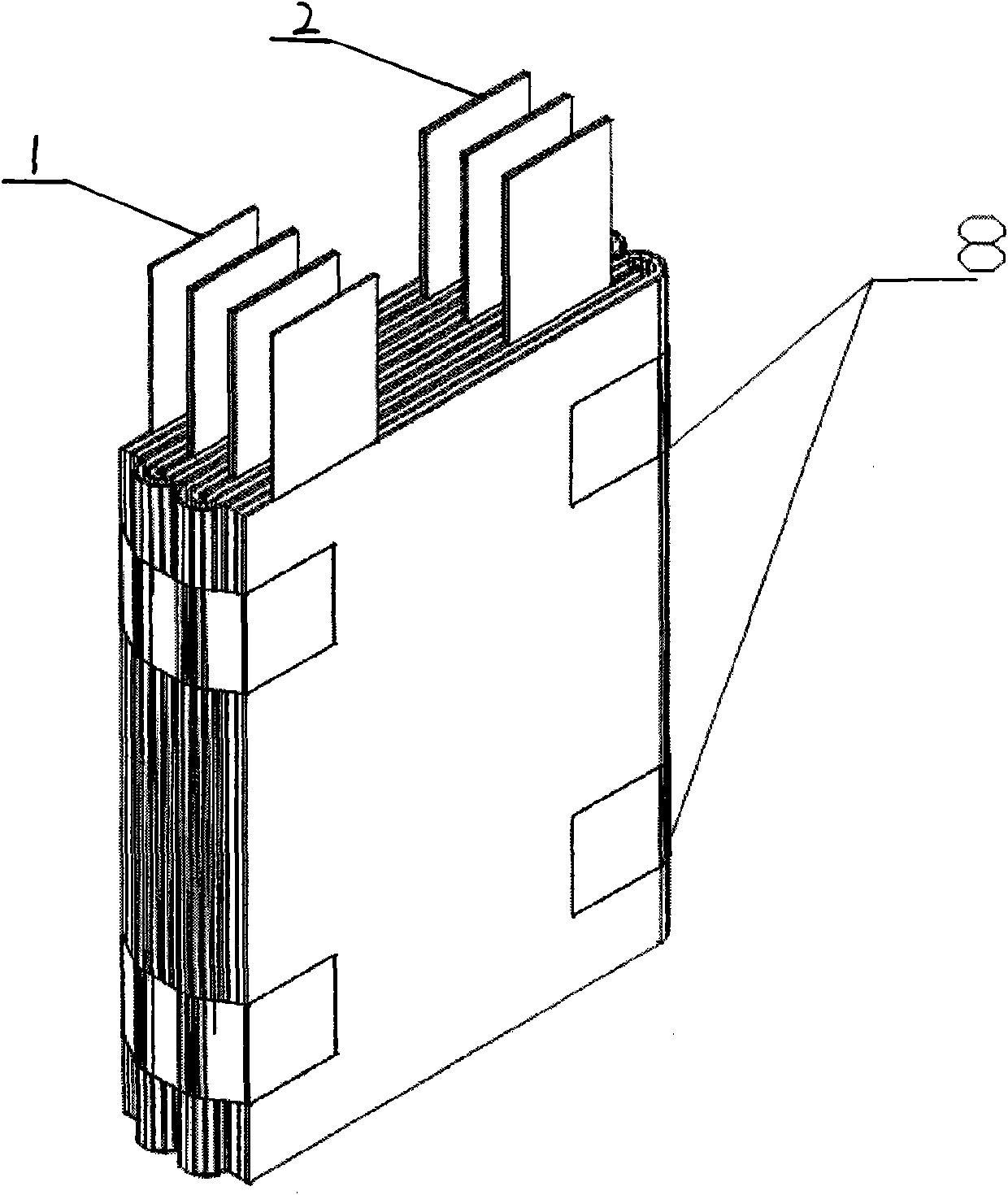

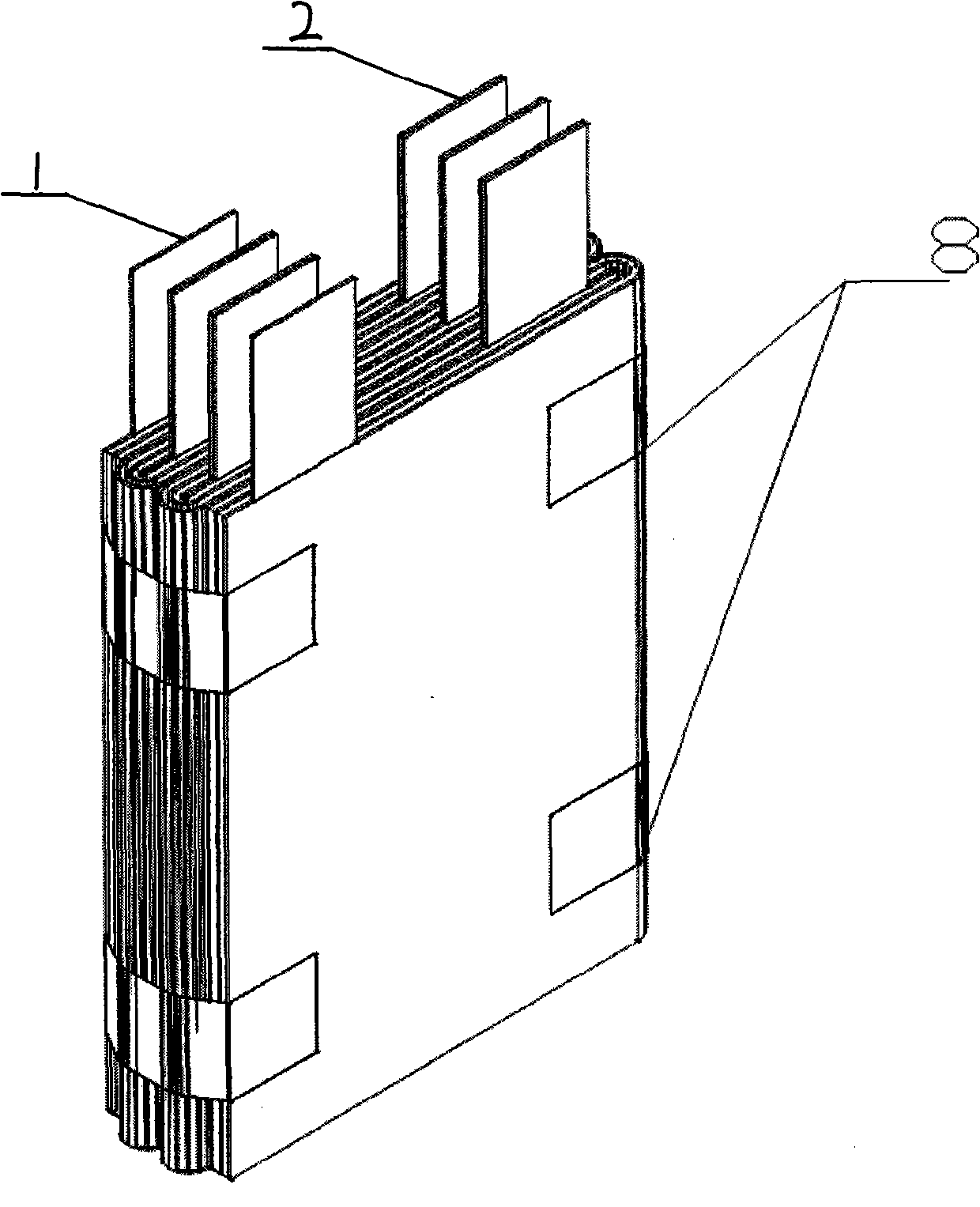

Method for manufacturing cells of power lithium ion batteries

A technology of lithium-ion batteries and manufacturing methods, which is applied in the field of manufacturing power-type lithium-ion battery cells, can solve problems such as low internal resistance, and achieve the effects of high production efficiency, shortened migration distance, and good overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Taking a 5Ah power type lithium manganese oxide battery as an example, under the condition that the formulation process of the mixing materials is completely consistent, the method of the present invention and the existing winding process and lamination process are respectively used to produce 10 batteries each. Wherein the present invention is specifically described as follows:

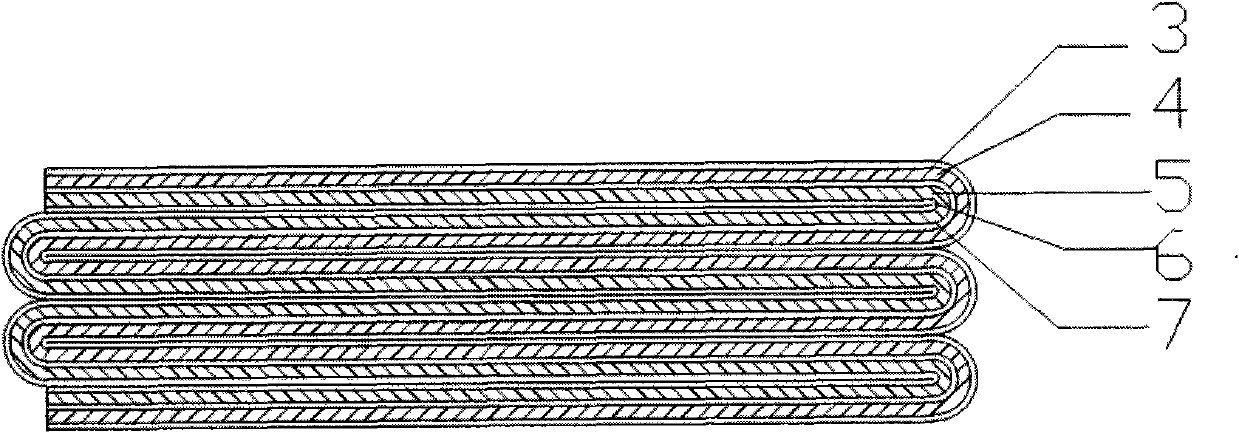

[0017] 1. The positive and negative active materials are respectively coated on one side of the positive and negative current collectors to form positive and negative pole rolls, and the surface density of the positive one side coated is 24g / cm 2 , the areal density of the negative electrode coated on one side is 8g / cm 2 , After the pole roll is rolled and cut, according to the width of the designed battery, the position of the reserved positive and negative tabs is determined, and the positive and negative pole pieces are punched out.

[0018] 2. The sides of the positive and negative pole p...

Embodiment 2

[0023] Taking an 8Ah high-power lithium iron phosphate battery as an example, under the condition that the formulation and process of the mixing materials are completely consistent, 10 batteries each are produced by the method of the present invention, the winding process and the stacking process. Wherein the present invention is specifically described as follows:

[0024] 1. The positive and negative active materials are respectively coated on one side of the positive and negative current collectors to form positive and negative pole rolls, and the surface density of the positive one side coating is 18g / cm 2 , the areal density of the negative electrode coated on one side is 9g / cm 2 , After the pole roll is rolled and cut, according to the width of the designed battery, the position of the reserved positive and negative tabs is determined, and the positive and negative pole pieces are punched out.

[0025] 2. The side of the positive and negative pole pieces covered with act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com