Slice-bearing table device with internal hoistable support column

A technology of sheet-carrying table and pillars, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of necessary use and waste of time, and achieve the effect of convenient taking and sending of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

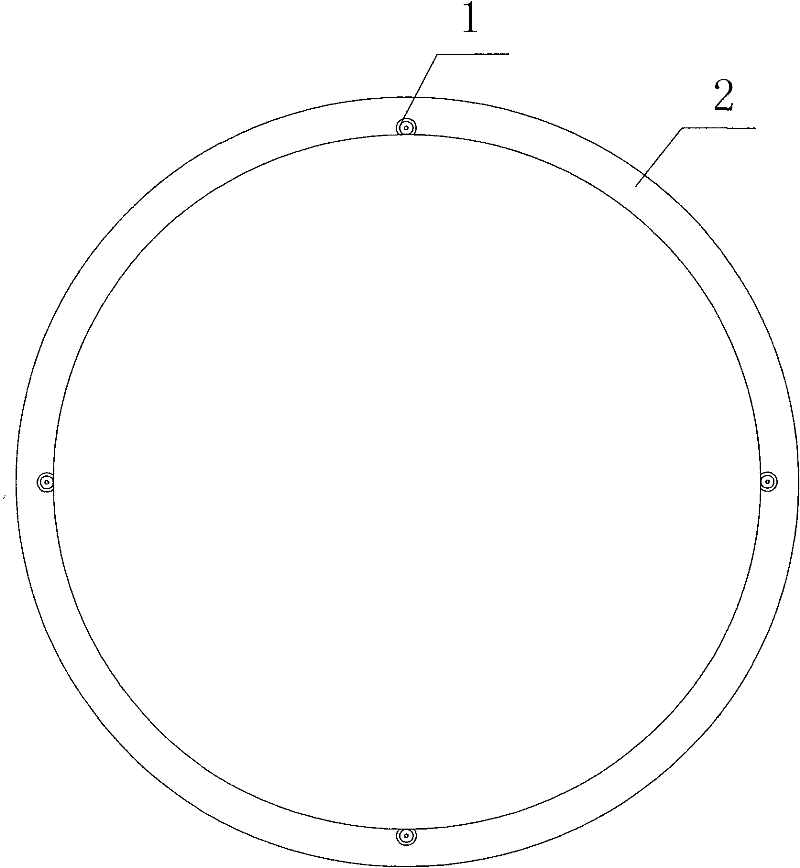

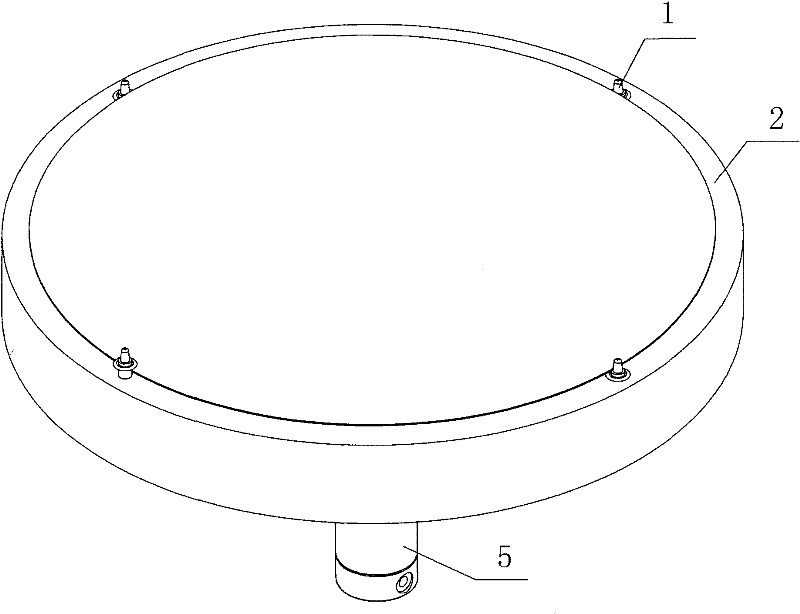

[0022] Such as Figure 1-3 As shown, the chip holder device with built-in liftable pillars of the present invention mainly includes: connection pillar 1, sheet holder 2, sealing ring 3, return spring 4, air supply rotary joint 5, liquid discharge port 6, etc., the specific structure is as follows :

[0023] The carrier table 2 is a concave groove structure, a cavity 8 is opened in the side of the carrier table 2, and a pipe 9 communicating with the cavity 8 is opened in the bottom of the carrier table 2, so that the air flow can flow from the carrier sheet The bottom of platform 2 passes to the bottom of pillar 1. A rotary joint 5 for air supply is installed on the bottom of the wafer holder 2, the air outlet end of the rotary joint 5 communicates with the pipeline 9, and the air intake end of the rotary joint 5 communicates with the air compressor. The cavity 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com