Spring operation mechanism

A technology of operating mechanism and return spring, which is applied in the direction of contact drive mechanism and power device inside the switch, etc. It can solve the problems of uncompact structure, no labor-saving mechanism, and large size of spring operating mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

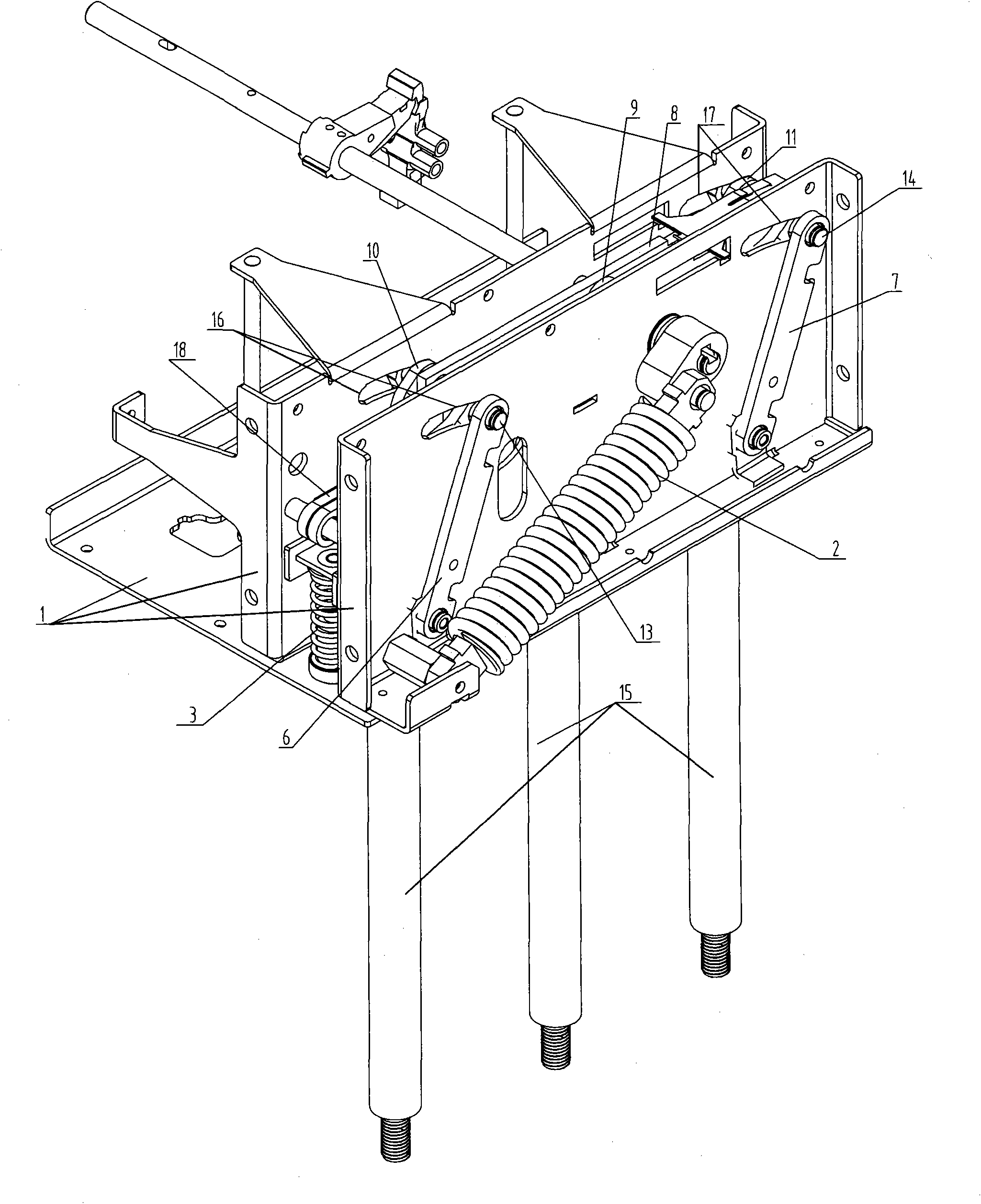

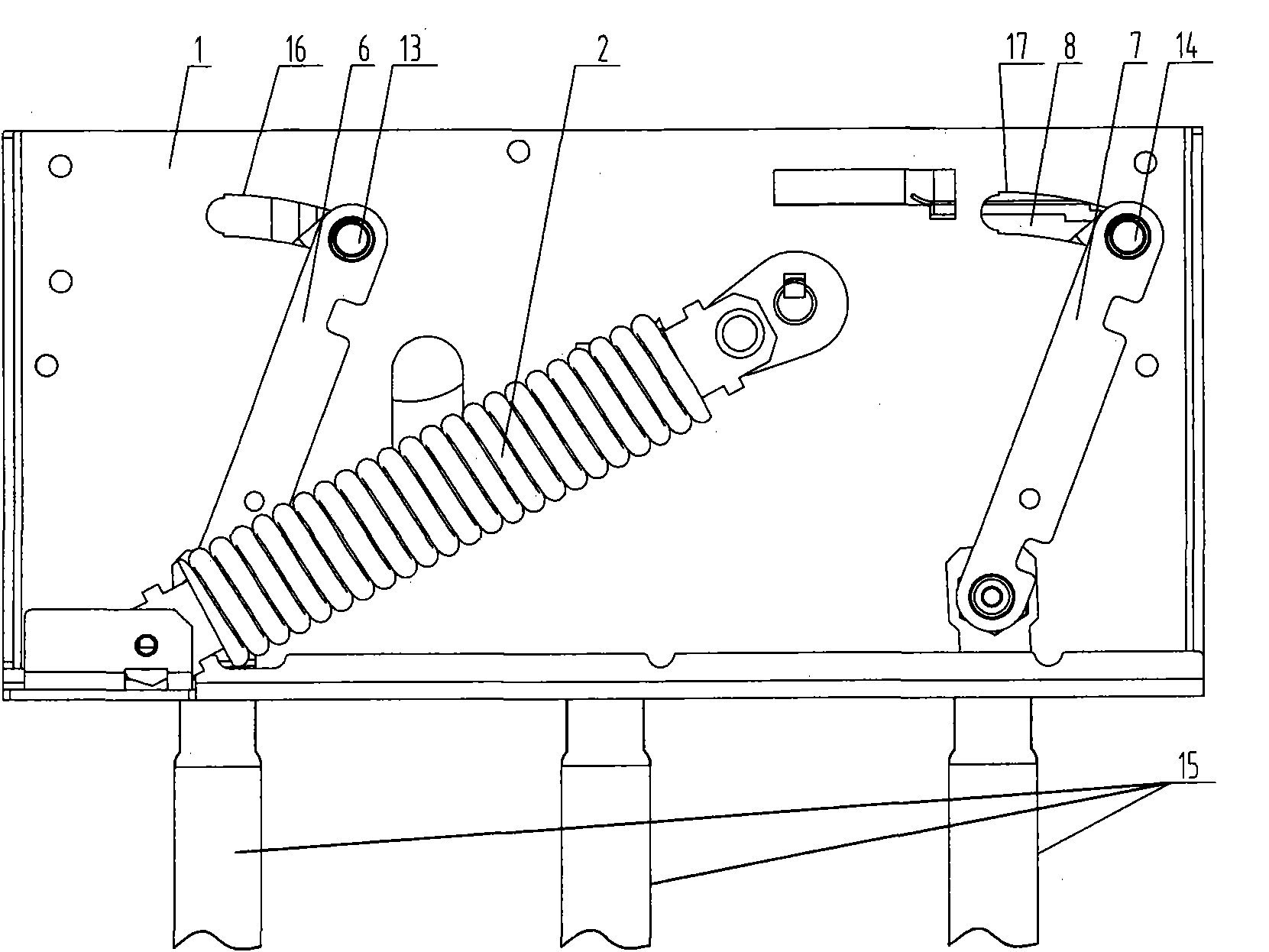

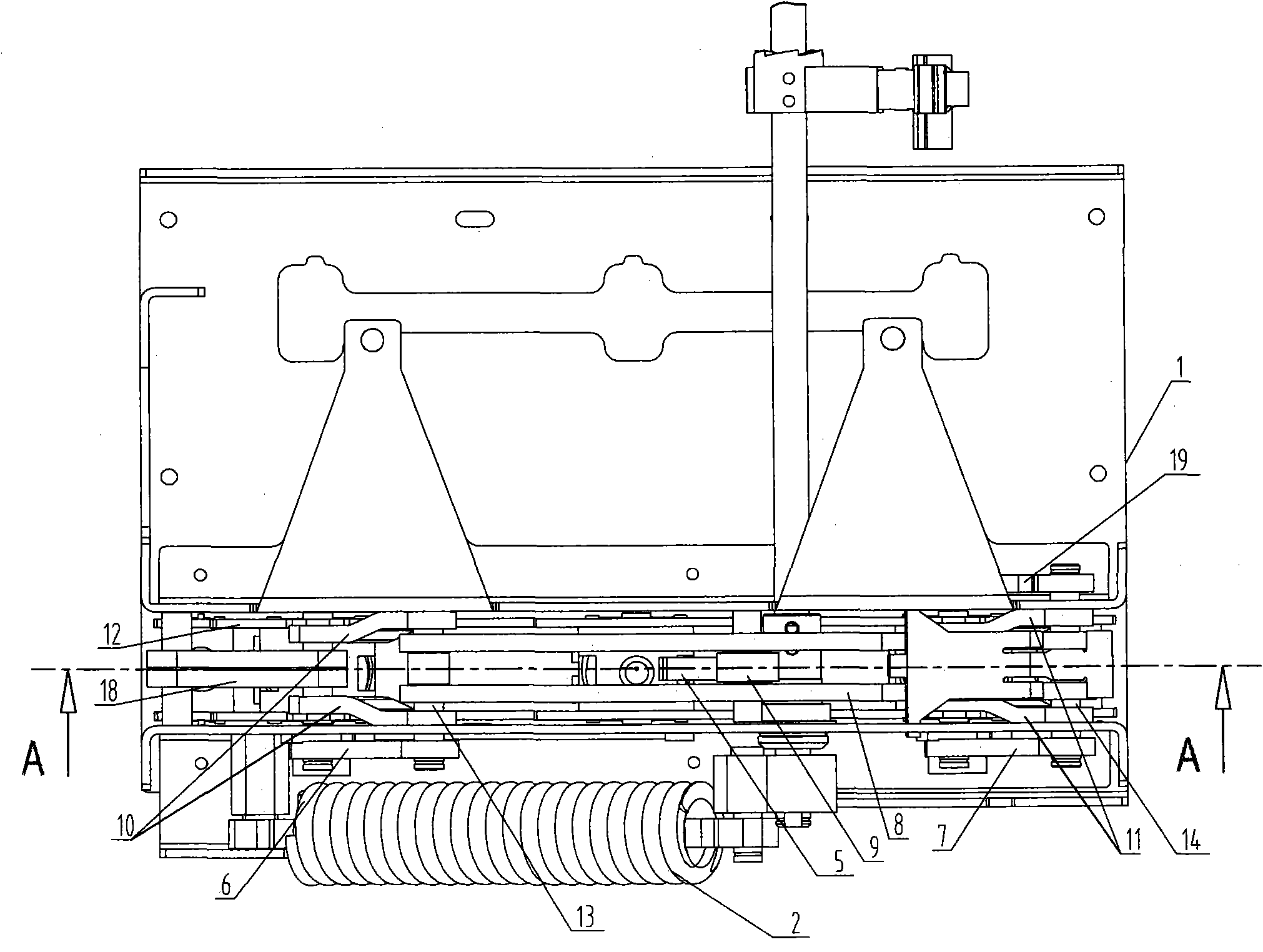

[0015] The present invention will be further described below in conjunction with accompanying drawing.

[0016] The spring operating mechanism of the present invention includes a mounting frame 1 as a frame, an energy storage spring 2, a return spring 3, a movable contact spring 4, a cam 5 and a parallelogram, and the parallelogram includes a first frame rod 6 , the second rack rod 7 and the first connecting rod 8, the first connecting rod 8 is equipped with a roller 9, the roller 9 is against or away from the cam 5, and it also includes a connecting rod that can be used to form a joint with the first rack rod 6 The second connecting rod 10 in the rod extreme position state, the third connecting rod 11 that can be used to form the connecting rod extreme position state with the second frame rod 7, the support frame driven by the second connecting rod 10 and the third connecting rod 11 12; the second connecting rod 10 and the third connecting rod 11 are equal in length and paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com