Novel furnace door structure of walking beam heating furnace

A walking heating furnace and furnace door technology, which is applied in the field of metallurgy, can solve problems such as steel structure deformation, affecting the quality of ingot hot rolling, and the furnace door cannot complete normal operations, so as to improve work reliability, avoid deformation, implement good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

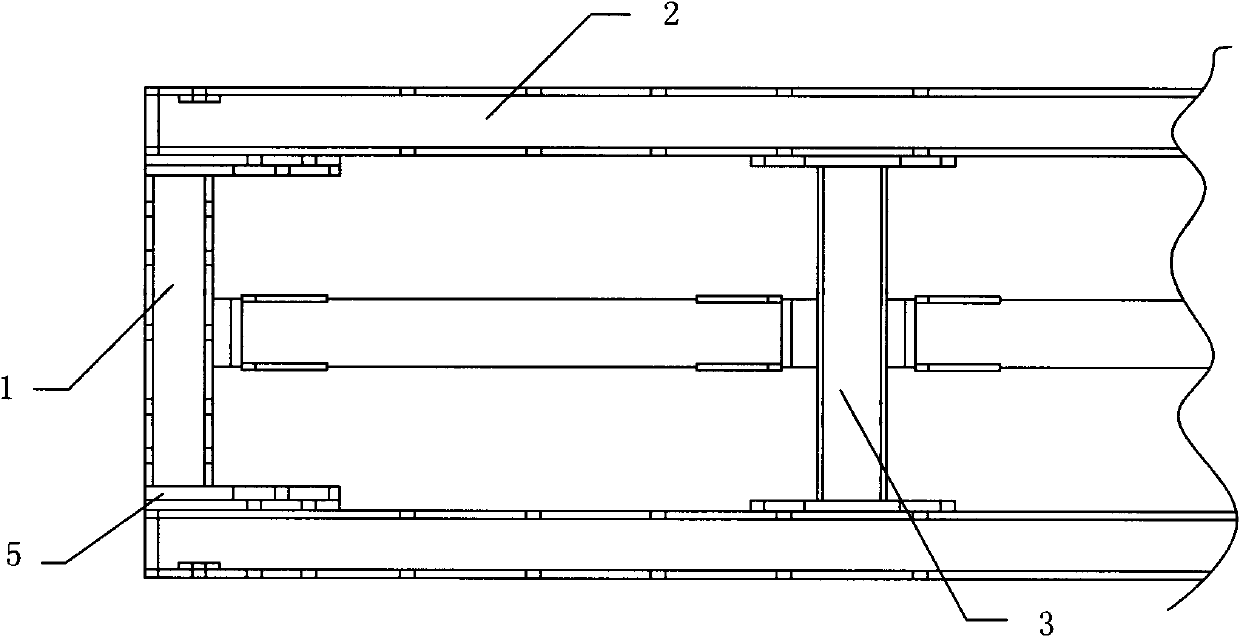

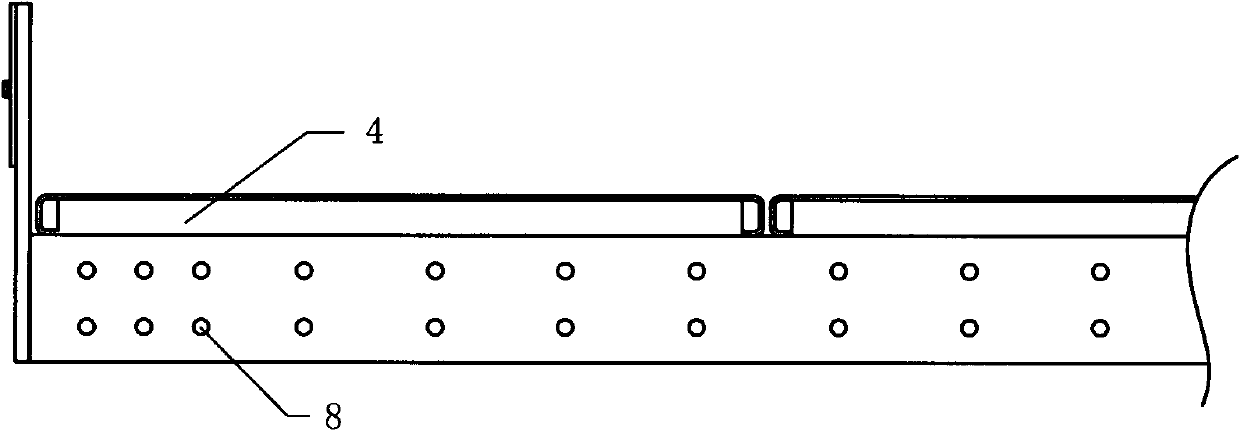

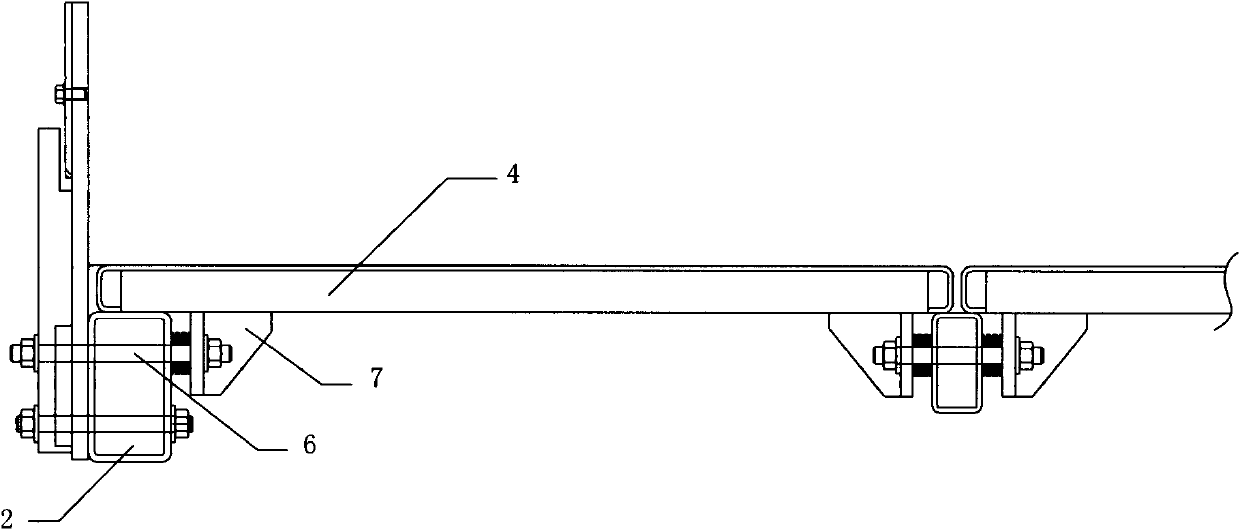

[0023] A furnace door structure of a new type of walking heating furnace, such as Figure 1~4 As shown, it includes a rectangular upright beam 1 and a rectangular crossbeam 2. The rectangular upright beam 1 and the rectangular crossbeam 2 form a rectangular skeleton. 3. Divide to form an accommodating space, in which a furnace skin steel plate block 4 is provided, and adjacent furnace skin steel plate blocks 4 do not touch each other, and form a reserved expansion space 9 between each other. further combined figure 1 It can be seen that both ends of the rectangular vertical beam 1 are provided with connecting plates 5, and the two ends of the rectangular beam 2 are connected with the corresponding connecting plates 5 to form a rectangular skeleton.

[0024] Specifically, the bottom surface of the furnace steel plate block 4 is provided with a fixing piece 7, and the fixing piece 7, the rectangular frame, the connecting plate 5, and the middle column 3 are all distributed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com