Clutch master cylinder capable of outputting displacement signal

A displacement signal and master cylinder technology, applied in the field of automobile clutch system, can solve the problems of inability to accurately judge the position of the clutch master cylinder piston, unable to provide accurate signals of the clutch system, etc., and achieve the effect of compact structure, satisfying signal requirements and low quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

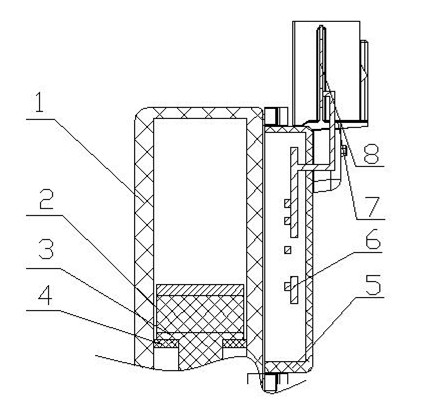

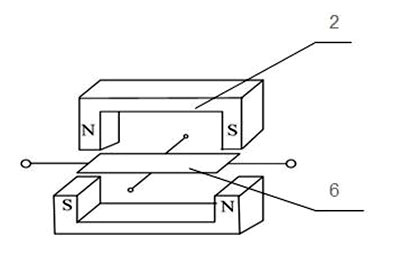

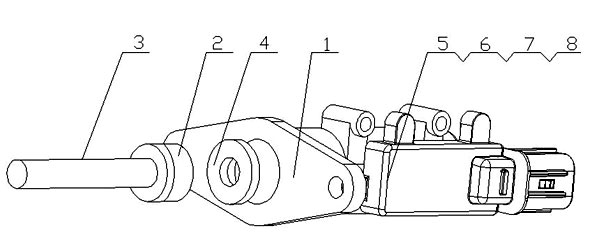

[0014] see figure 1 with image 3 A clutch master cylinder capable of outputting displacement signals is shown, including a piston 2 matched with the inner wall of the cylinder body 1, a push rod 3 connected with the piston, an inner ring and a push rod matched with a sealing ring, and an outer ring matched with the inner wall of the cylinder 4; the piston 2 is made of magnetic material with an alnico magnet, which can generate a magnetic field;

[0015] A Hall element 6 and a connector connecting body 7 are integrated with the sensor housing 5 by casting, the wiring harness connector 8 is connected with the connector connecting body 7 by injection molding, and the signal is output by the wiring harness connector 8; the sensor housing 5 and the The cylinder body 1 is pressed into one body through interference fit, and the Hall element 6 in the sensor housing 5 corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com