Mechanical coolant pump

A coolant pump, mechanical technology, applied in the direction of engine cooling, coolant flow control, mechanical equipment, etc., can solve the problems of pivot cover jamming, achieve low sliding friction and improve energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

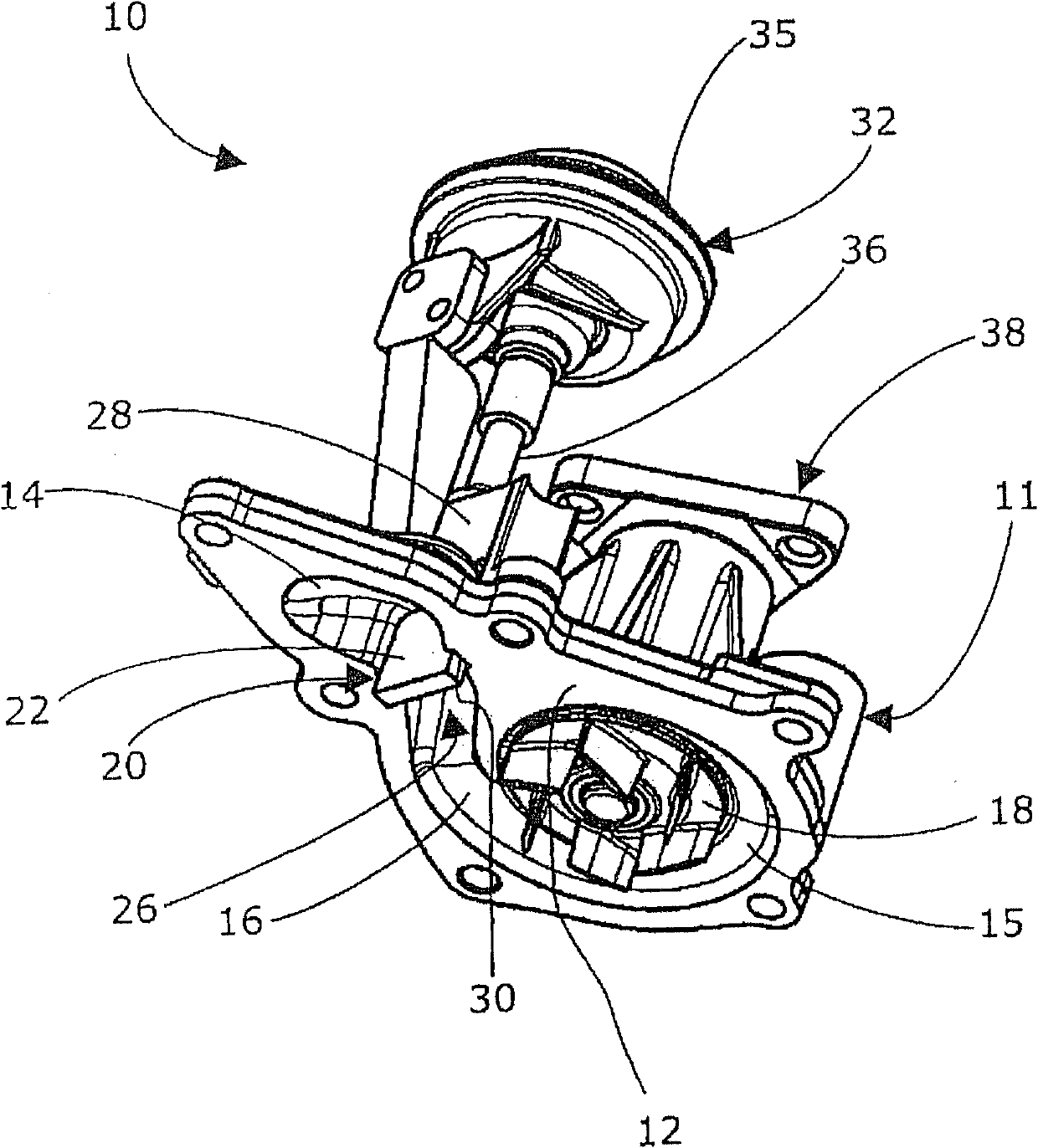

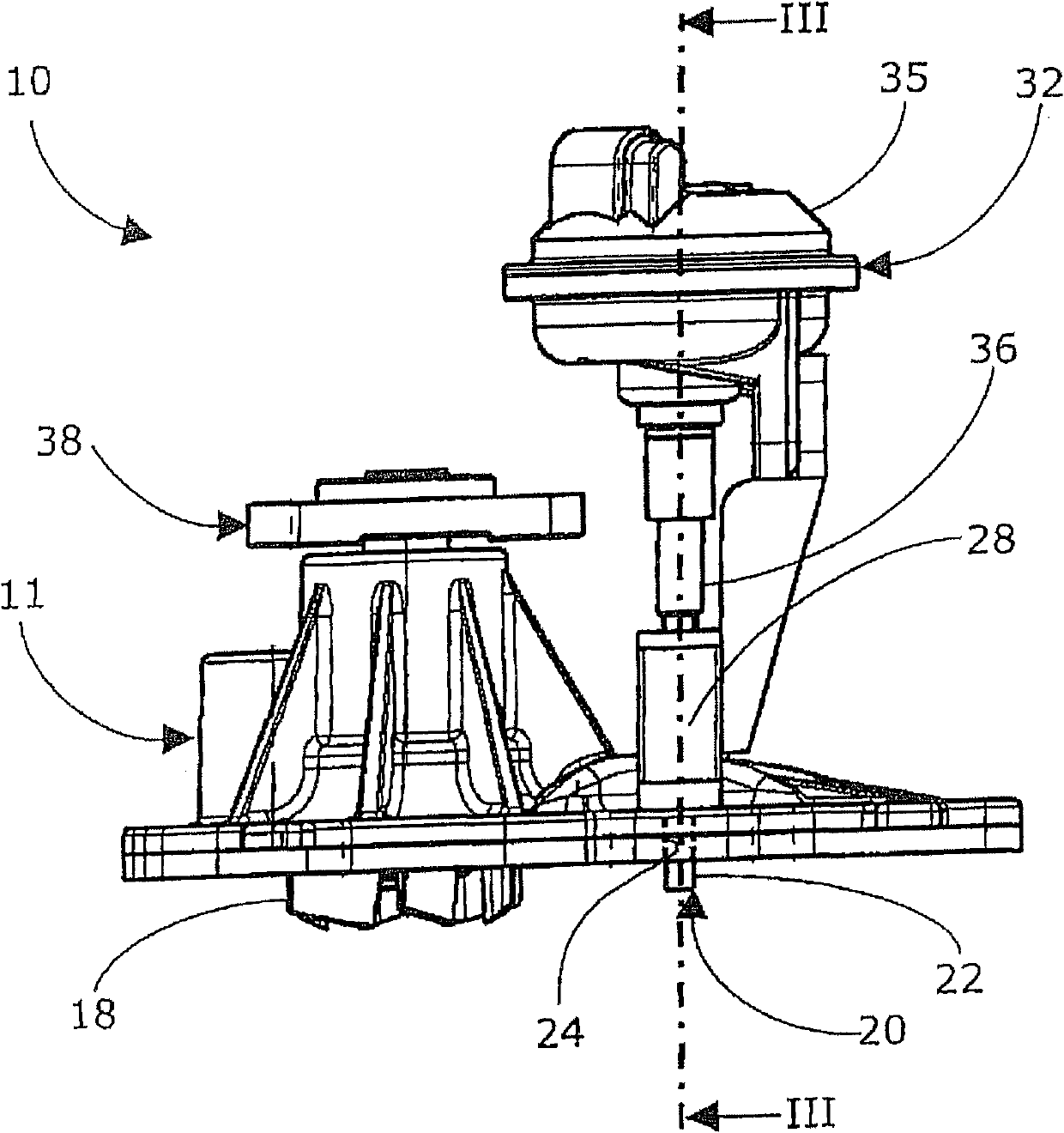

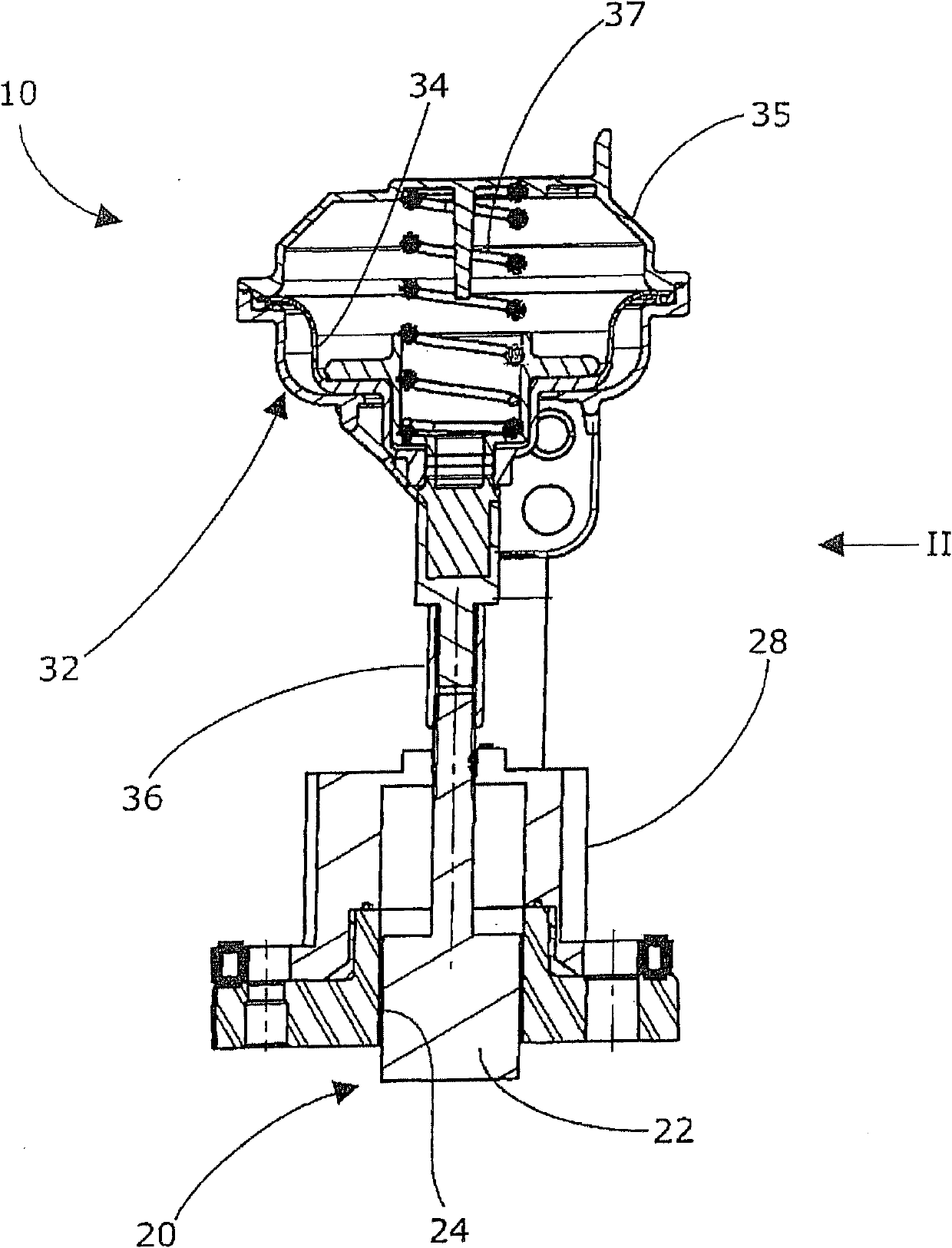

[0022] exist figure 1 In , a mechanical coolant pump 10 for an internal combustion engine is shown. The mechanical coolant pump 10 comprises a main pump body 11 whereby the main pump body is mounted directly to the engine block via a flange 12 or may have a cover plate (not shown).

[0023] The main pump body 11 houses a rotatable impeller 18 which sucks in coolant axially and pumps the coolant radially outward into a volute 15 . The impeller 18 is driven by the combustion engine using a drive belt (not shown) which drives a drive wheel 38 of the mechanical coolant pump 10 . The coolant flows from the volute 15 into the outlet channel 16 due to centrifugal force and passes through the outlet valve 20 to the outlet opening 14 . An outlet valve 20 is located at the end of the outlet channel 16 .

[0024] The outlet valve 20 comprises a movable flat valve plate 22 which is movable within the cross-section of the outlet channel 16 through a passing slit 24 in an outlet channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com