Porthole for ship

A technology for ships and portholes, applied in the field of windows, can solve the problems of easy burning of annular sealing strips, no heat insulation performance, no shielding performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

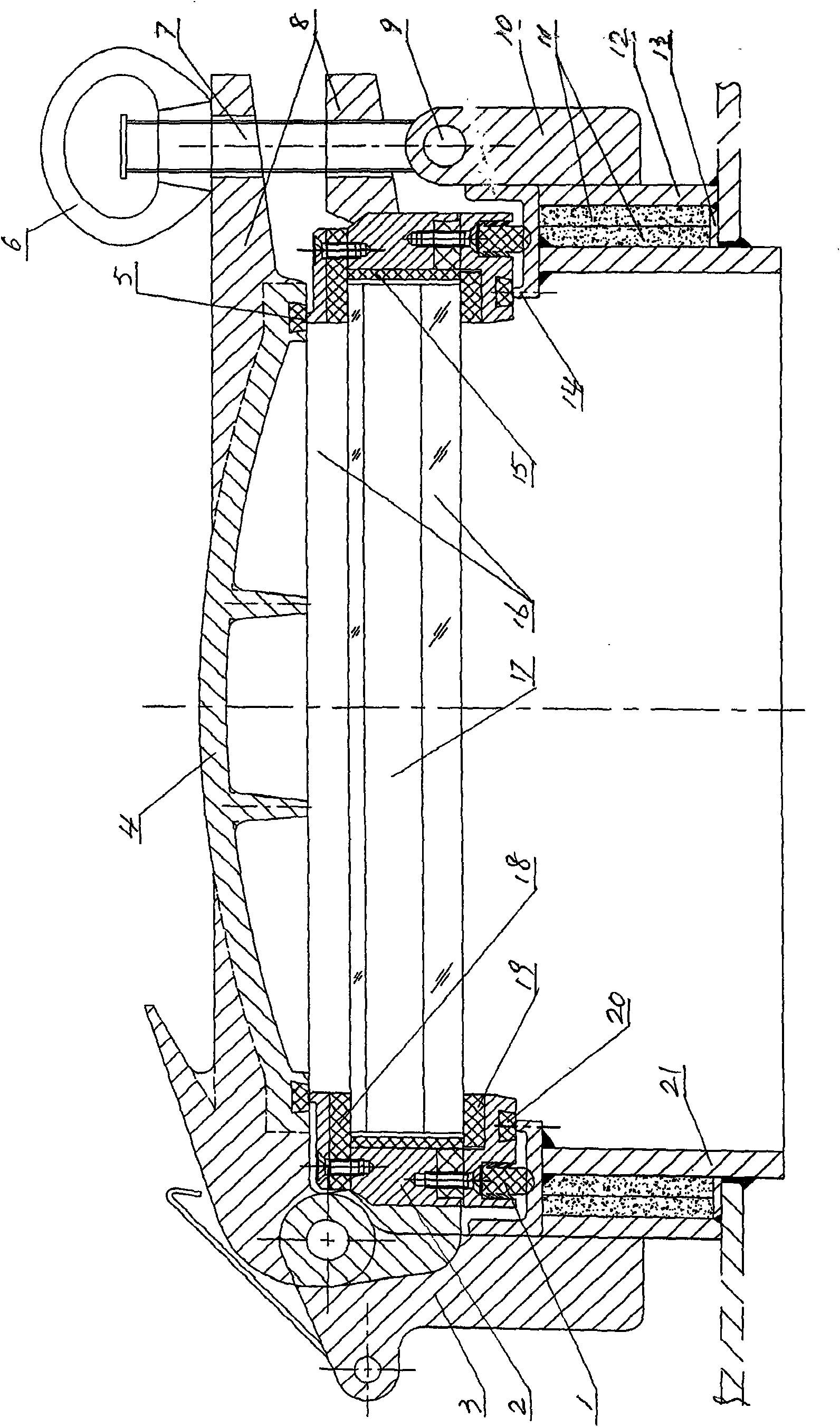

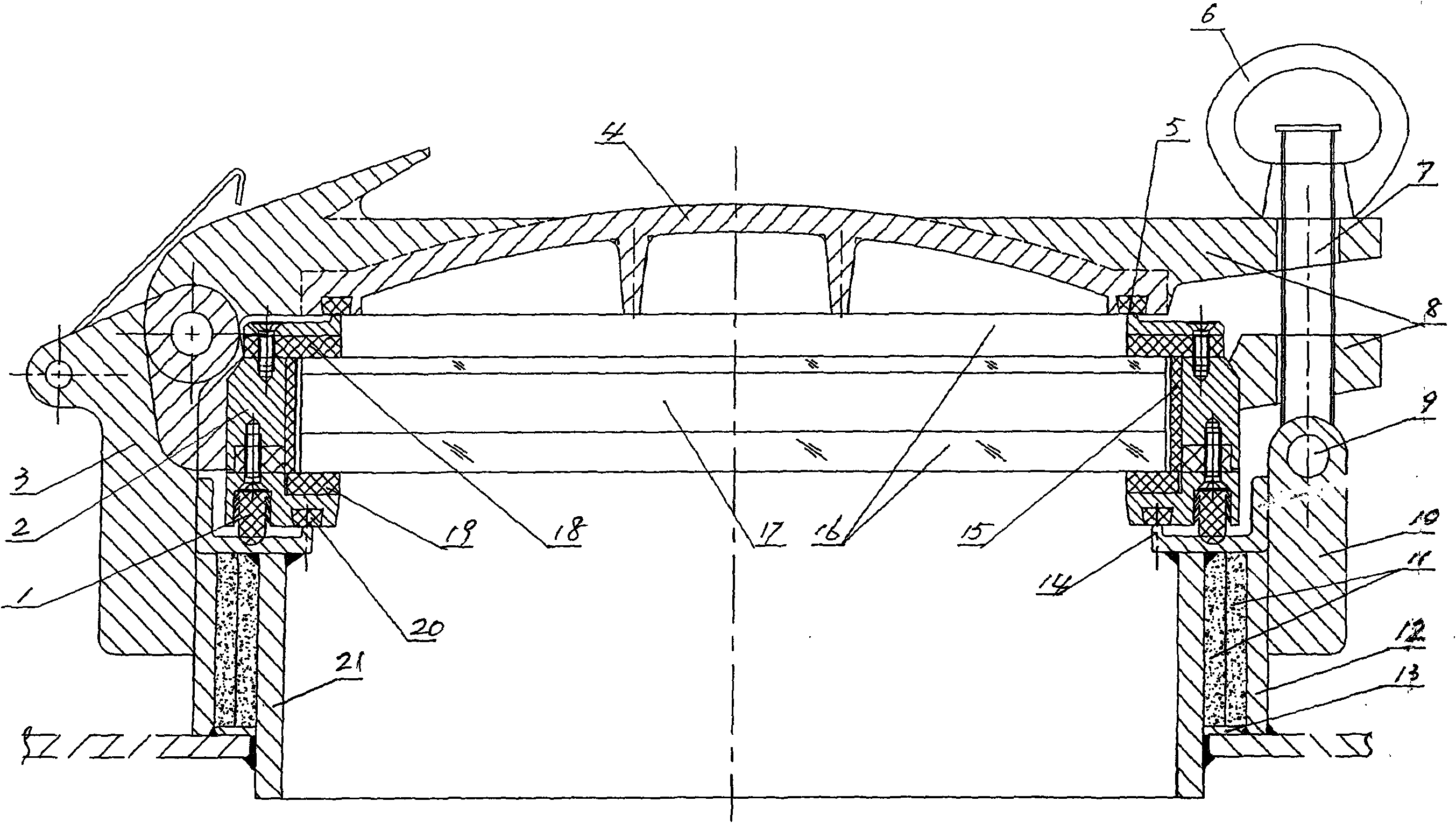

[0009] Such as figure 1 As shown, the ship porthole of the present invention includes a window frame, and the window frame 21 is welded after being surrounded by flat steel, and its outer end has a window leaf and a gland 4 sequentially from the inside to the outside. One side of the cover 4 is hinged on the corresponding side wall of the outer end of the window frame 21 by means of the same hinge 3; side; the window frame 21 corresponding to the pin seat 10 and the side of the gland 4 are welded with ear plates 8, and U-shaped notches are processed on the ear plates 8; pin 7. The locking pin 7 is a screw rod, and a handle 6 is provided at one end thereof. The handle 6 is ring-shaped, and a radial screw hole is processed on it, and it is screwed on one end of the locking pin 7 by means of the radial screw hole. The other end of the locking pin 7 is pinned to the pin seat 10 by means of a pin shaft 9 . In the locked state, the locking pin 7 snaps into the U-shaped notch on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com