Light absorber, filter glass prepared from light absorber, and method for preparing filter glass from light absorber

A technology of light absorber and filter glass, applied in the field of filter glass and its preparation, can solve the problems of low light transmittance, inability to meet light requirements, inability to use anti-glare equipment, complicated production process, etc. Conducive to technology update and promotion, preventing glare, and reducing the difficulty of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

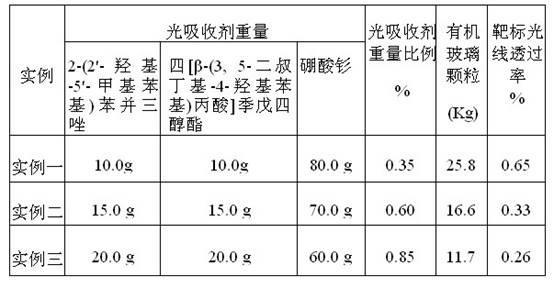

[0019] Weigh 10 g of 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol 10g, 80g of samarium borate, mixed with dichloromethane and dissolved to form a solution, 1 / 2 of the obtained solution was evenly sprayed on 25.8Kg plexiglass particles, melted, cooled and granulated, and then the remaining 1 / 2 of the solution was evenly sprayed on the On granulation, melting, cooling and granulation, extrusion method to produce plate-shaped plexiglass, and polishing treatment, the transmission and filtration of target light is 0.65%. See Table 1 for details.

Embodiment 2

[0021] Weigh 15g of 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester 15g, 70g of samarium borate, mixed with dichloromethane and dissolved to form a solution, 1 / 2 of the obtained solution was evenly sprayed on 16.6Kg plexiglass particles, melted, cooled and granulated, and then the remaining 1 / 2 of the solution was evenly sprayed on the On granulation, melting, cooling and granulation, extruding method to produce plate-shaped organic glass, and polishing treatment, the transmission and filtration of target light is 0.33%. See Table 1 for details.

Embodiment 3

[0023] Weigh 20 g of 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 20g, 60g of samarium borate, mixed with dichloromethane and dissolved to form a solution, 1 / 2 of the obtained solution was evenly sprayed on 11.7Kg plexiglass particles, melted, cooled and granulated, and then the remaining 1 / 2 of the solution was evenly sprayed on the On granulation, melting, cooling and granulation, extrusion method to produce plate-shaped organic glass, and polishing treatment, the transmission and filtration of target light is 0.26%. See Table 1 for details.

[0024]

[0025] Table 1

[0026]

[0027] It can be seen from Table 1 that the product of the present invention can effectively prevent the transmission of glare light, the transmittance is only 0.26% to 0.65%, the product performance is stable, and the anti-glare effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com