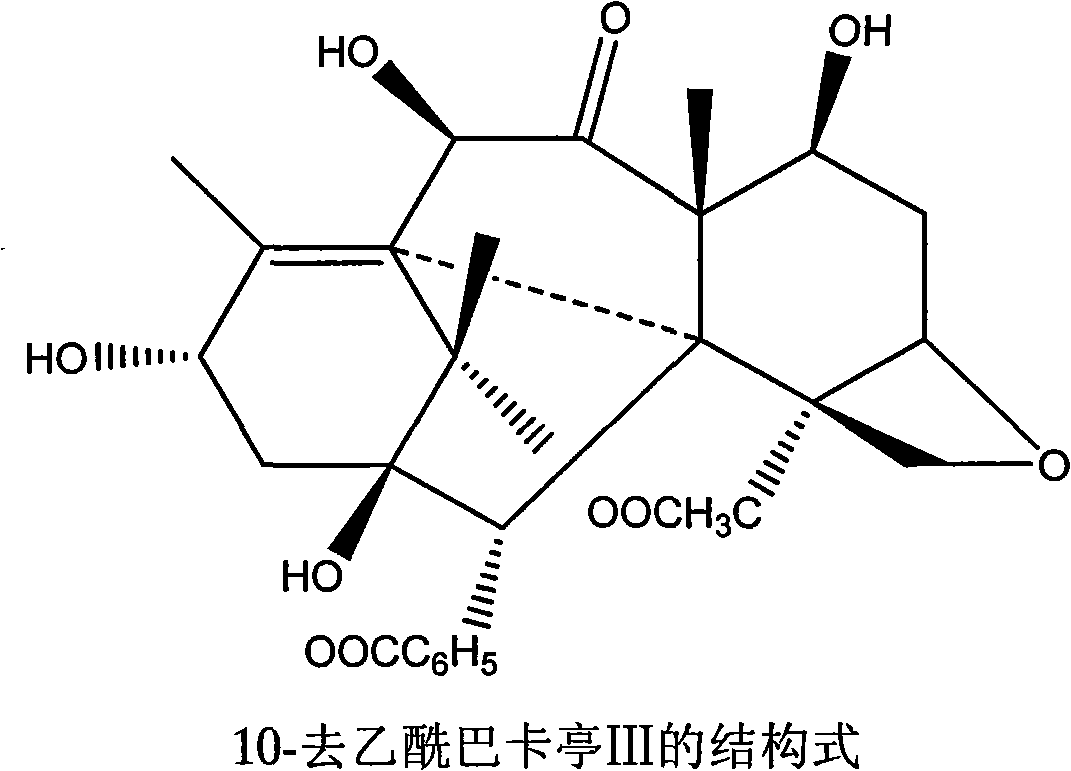

Method for extracting 10-deacetyl baccatin III from branches and leaves of taxus chinensis

A technology of yew branches and leaves and acetyl bacca, which is applied in the field of extraction of medicinal compounds to achieve the effects of reducing losses, shortening the process flow, and shortening the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Take 100kg of artificially planted southern yew branches and leaves, crush them into 20-mesh powder, put them into an ultrasonic tank, add 100L of water at the same time, ultrasonicate at 60°C for half an hour, and filter. Add 60L, 30L, and 30L dichloromethane three times for extraction, combine the dichloromethane phases and concentrate to obtain 310.7g of extract, with a content of 2.58%.

[0016] 2. Add 310.0g of extract to 310ml of acetonitrile, and heat to 50-80°C in a water bath to dissolve. Put in -10°C environment for 24 hours, filter the crystals, and dry at low temperature to obtain 29.58g of white powder with a content of 24.92%.

[0017] 3. Dissolve 29.08g of 24.92% white powder with 580ml of dichloromethane:methanol (volume ratio 4:1) at 50°C, cool to -10°C, filter, and dry at low temperature to obtain 7.77g of white powder. 80.28%.

[0018] 4.7.67g of white powder with a content of 80.28%, heated and dissolved with 190ml of dichloromethane:methanol (1...

Embodiment 2

[0022] 1. Take 100kg of artificially planted southern yew branches and leaves, crush them into 20-mesh powder, put them into an ultrasonic tank, add 200L of water at the same time, ultrasonicate at 60°C for half an hour, and filter. Add 80L, 30L, and 20L dichloromethane three times for extraction, combine the dichloromethane phases and concentrate to obtain 312.3g of extract, with a content of 2.88%.

[0023] 2. Add the extract to 900ml of acetonitrile, and heat it in a water bath to 50-80°C to dissolve. Put in -10°C environment for 24 hours, filter the crystals, and dry at low temperature to obtain 30.27g of white powder with a content of 25.01%.

[0024] 3. Dissolve 30.17g of 25.01% white powder with 600ml of dichloromethane:methanol (volume ratio 4:1) at 50°C, cool to -10°C, filter, and dry at low temperature to obtain 8.03g of white powder. 81.31%.

[0025] 4. 7.93g of white powder with a content of 81.31% was dissolved by heating at 50°C with 190ml of dichloromethane:me...

Embodiment 3

[0029] 1. Take 100kg of artificially planted southern yew branches and leaves, crush them into 20-mesh powder, put them into an ultrasonic tank, add 300L of water at the same time, ultrasonicate at 60°C for half an hour, and filter. Add 70L, 50L, and 30L dichloromethane three times for extraction, combine the dichloromethane phases and concentrate to obtain 325.9 g of extract, with a content of 2.57%.

[0030] 2. Add the extract to 600ml of acetonitrile, and heat it in a water bath to 50-80°C to dissolve. Put in -10°C environment for 24 hours, filter the crystals, and dry at low temperature to obtain 29.92g of white powder with a content of 25.52%.

[0031] 3. Dissolve 29.82g of 25.52% white powder with 600ml of dichloromethane:methanol (volume ratio 4:1) at 50°C, cool to -10°C, filter, and dry at low temperature to obtain 7.82g of white powder. 81.59%.

[0032] 4. 7.72g of white powder with a content of 81.59% was dissolved by heating at 50°C with 190ml of dichloromethane:m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com