Hydraulic manipulator paw for assembling and disassembling square articles

A technology of mechanical claws and hydraulic machinery, which is applied in the field of hydraulic machinery, can solve the problems of limited stacking height, failure to meet the stacking requirements of square objects, hydraulic manipulators have not yet been seen, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

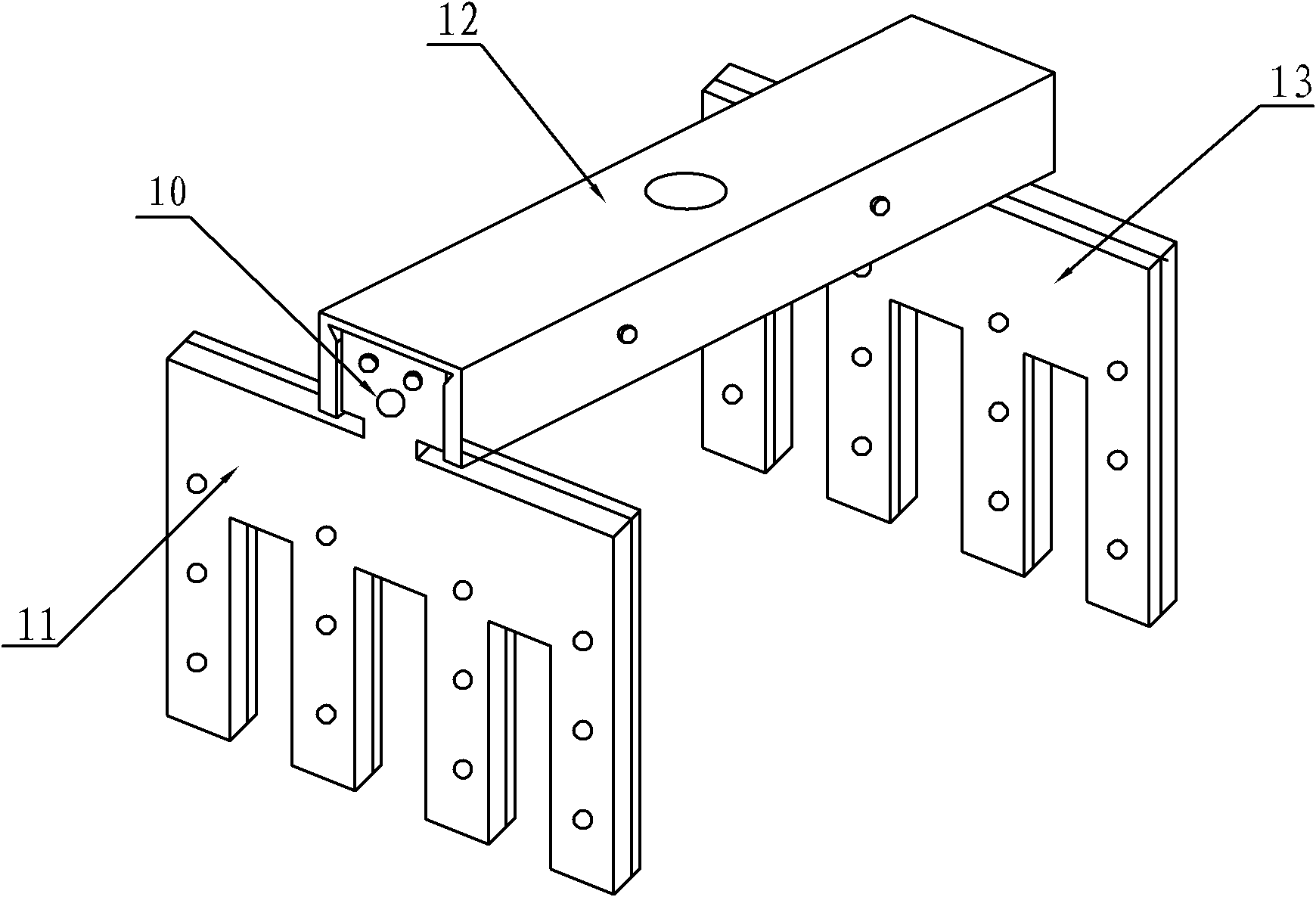

[0008] Such as figure 1 Shown, a kind of hydraulic mechanical gripper that is used for square object loading and unloading, a gripper frame 11 that is connected on the hydraulic mechanical arm, described gripper frame 11 is channel steel structure, is fixedly installed in the middle part of the groove of channel steel structure There is a double push rod hydraulic cylinder with push rods 10 reversely and synchronously moving. The outer end of each push rod is connected to a movable gripper 11. The upper end of the gripper is vertically embedded in the slideway in the groove of the channel steel structure. The inner side of the claw is fixedly provided with a rubber pad 13 .

[0009] When the object is clamped, the hydraulic pump supplies oil to the claw cylinder 10, and the claw cylinder 10 stretches out. At this time, the two claws 11 also move in opposite directions under the drive of the claw cylinder 10. Stop the oil supply of the claw oil cylinder 10 when reaching the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com