Assembly welding technology of lifting frame of heating furnace

A technology for raising and lowering frames and heating furnaces, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc. It can solve problems such as inability to trim, affect the assembly of beams 2, increase the workload of manual research and matching, and achieve production efficiency and product quality. Improve and reduce assembly and debugging time, and reduce the effect of manual research and matching processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The welding process of the lifting frame of the heating furnace provided by the present invention has the following main steps:

[0038] 1. Process preparation:

[0039] 1.1 Check whether the equipment and process equipment used are in normal working condition.

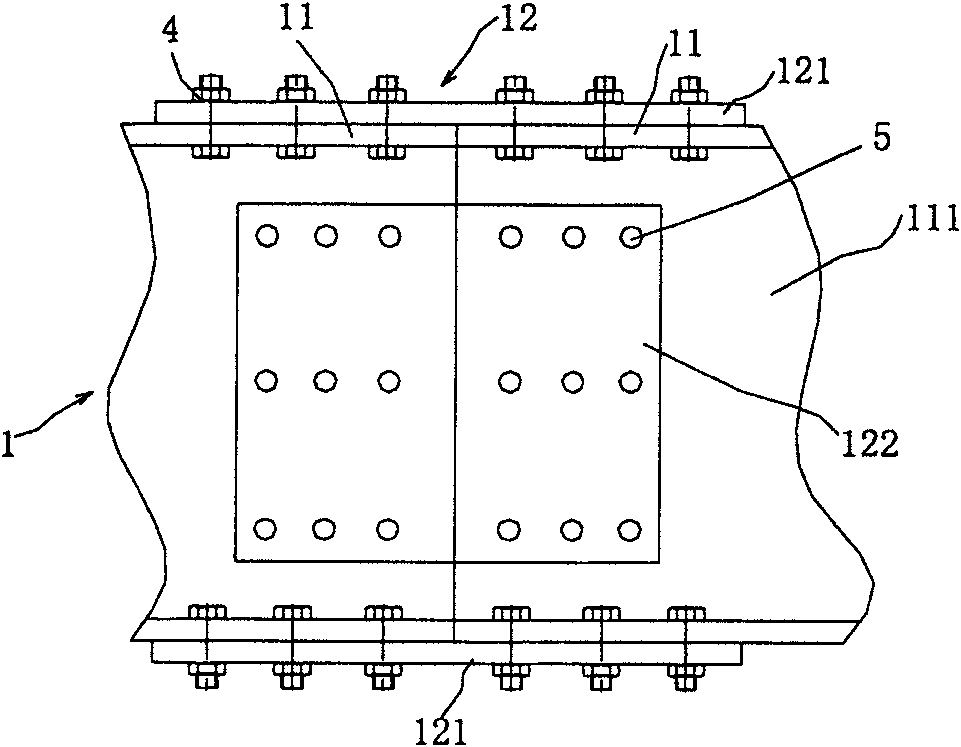

[0040] 1.2 Familiar with the drawings and technical requirements, understand the use and structure of the product, the function of each part and the connection relationship between them. The component connecting plates are connected, and the two longitudinal beam frames are made symmetrically. The frame is assembled by four sets of longitudinal beam components, ten beams and sixteen inclined beams.

[0041] 1.3 Check whether all parts are complete according to the parts list of the drawing.

[0042] 1.4 Check whether the size of the parts meets the requirements and whether the marking is correct according to the drawings.

[0043] Second, the specific process steps and content:

[0044] 1. The layout of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com