Core shooter guide rail and roller

A technology of core shooter and guide rail, which is applied in the direction of core, molding machine parts, casting and molding equipment, etc. It can solve the problems of upper part moving stuck and unable to move, stopping to clean the track, affecting production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

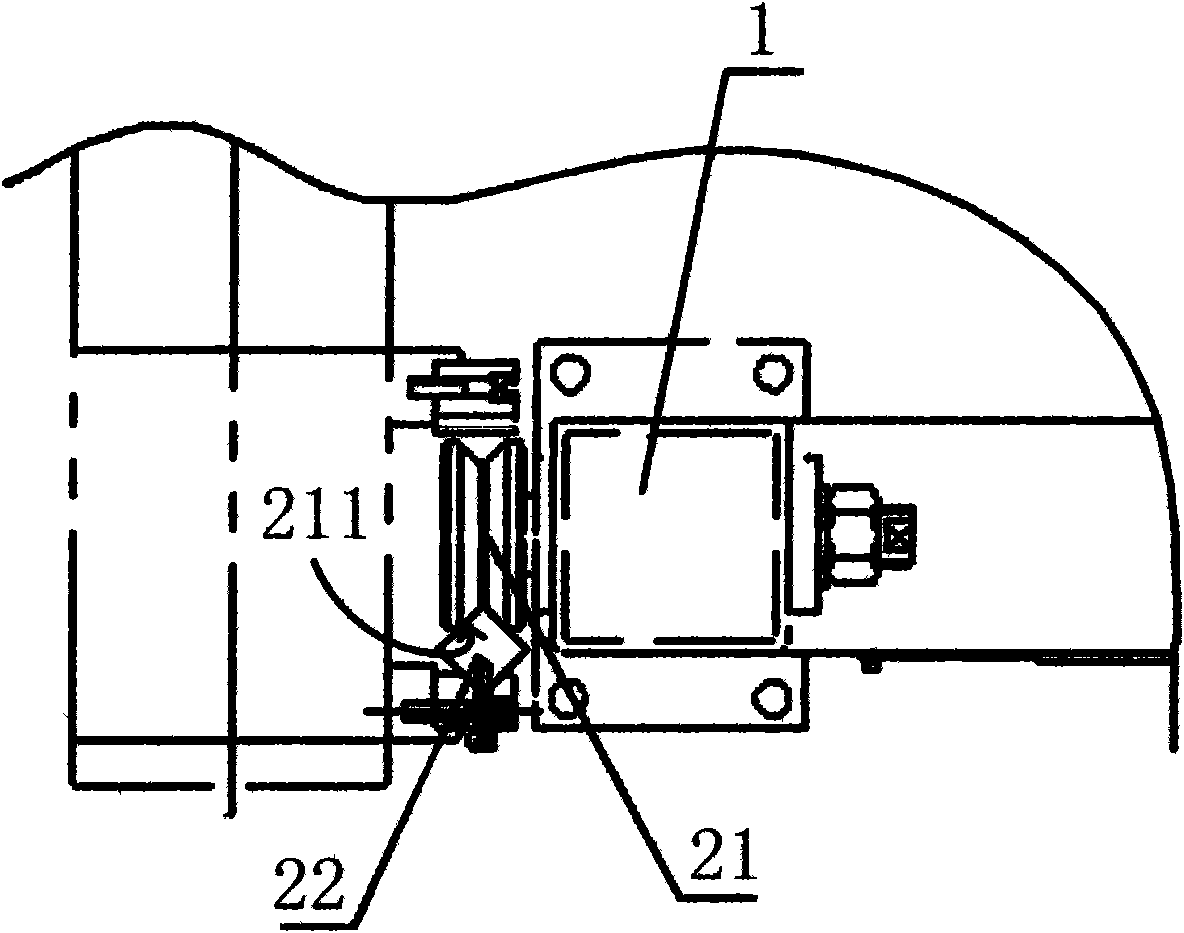

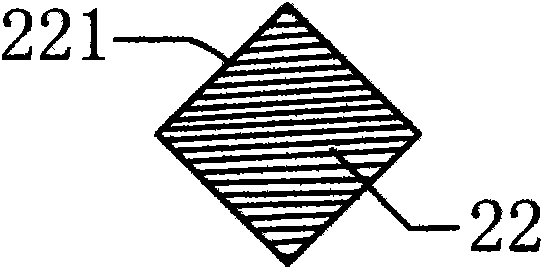

[0020] Such as figure 1 and figure 2 The core-shooting guide rail and rollers shown are fixed by the V-shaped wheel fixed support, and the V-shaped roller realizes positioning. The lower end of the V-shaped roller is placed with a guide rail 22, and the guide rail surface 221 at the upper end of the guide rail 22 is in an inverted V shape at 90 degrees. In this way, the scattered core sand cannot enter the contact gap between the guide rail and the roller, but falls along the slope of the inverted V-shaped guide rail surface.

[0021] The guide rail can be obtained only by rotating the original ordinary plane guide rail by 45°, and at the same time, it is necessary to change the original flat wheel type rolling wheel into a V-shaped wheel. With a slope of 45°, the sand will be scattered to the bottom more easily, which will greatly reduce the problem of the upper part being stuck when moving.

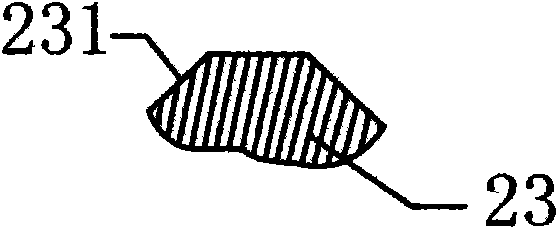

[0022] Such as image 3 Another section of the guide rail shown shows that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com