Self-oscillation jet impact-type nozzle for atomizing complex fluids

A self-excited oscillating jet and impact technology, which is applied in the direction of liquid injection devices, injection devices, injection devices, etc., can solve the problems of high manufacturing cost, complex nozzle structure, and poor nozzle atomization effect, and achieve simple structure, Good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

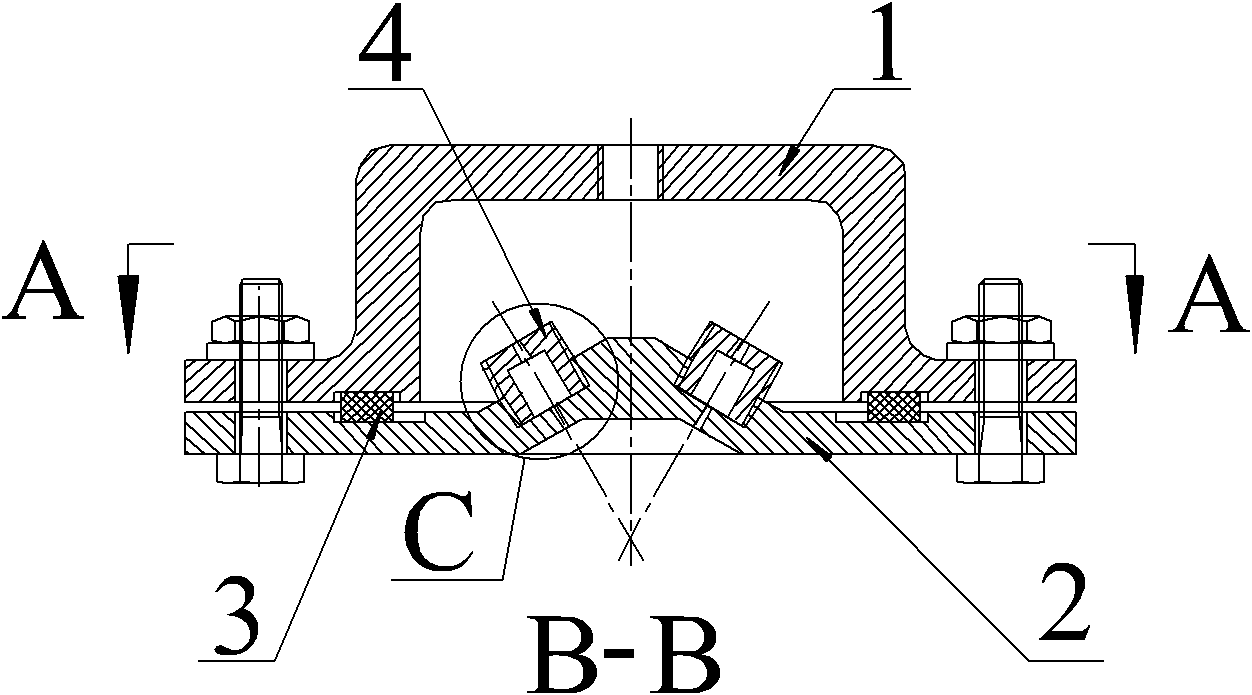

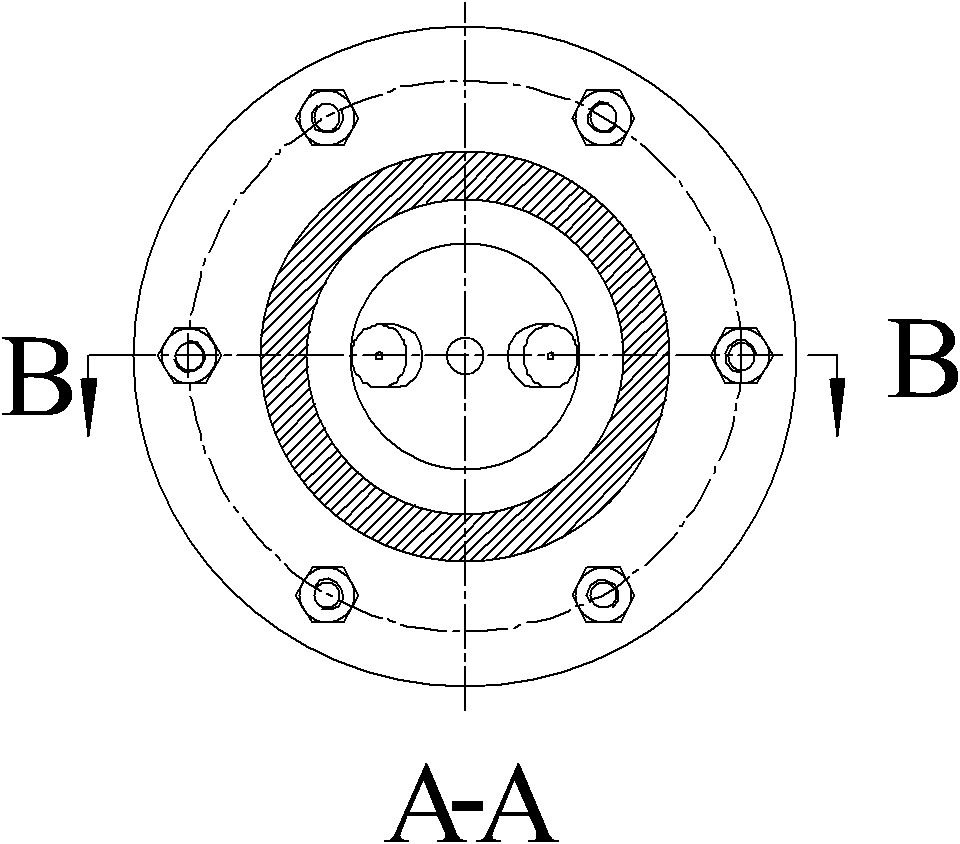

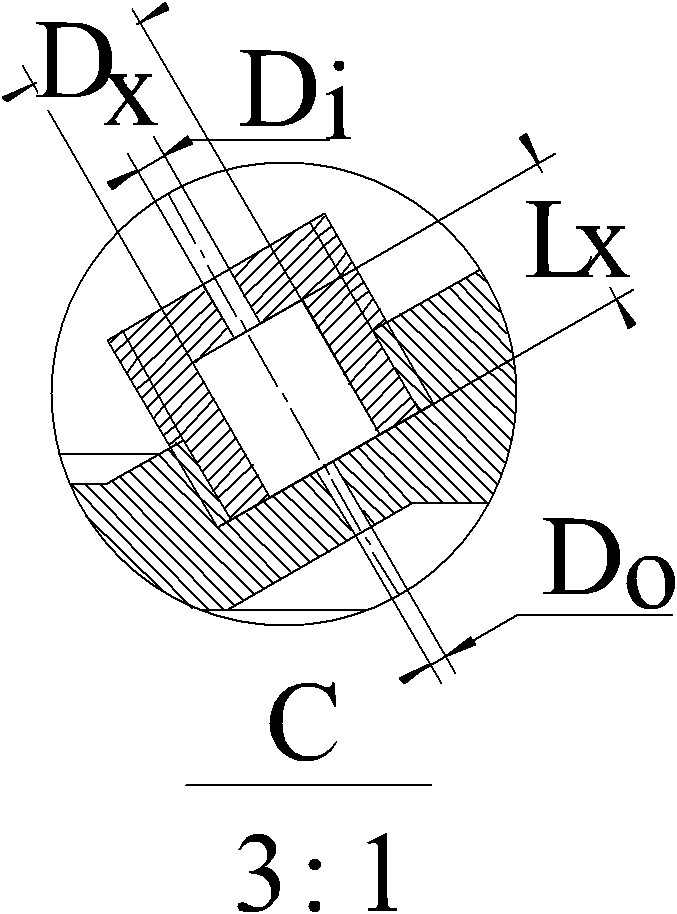

[0025] Example one: Such as figure 1 , 2 As shown in Fig. 3, a self-excited oscillating jet impinging nozzle used for the atomization of complex fluids of the present invention is mainly composed of a liquid collection chamber housing 1, an injection panel 2, a sealing gasket 3 and a resonance cavity housing 4. Figure 4 , 5 It is a liquid collection chamber housing 1 composed of a liquid collection chamber inlet 11 and a liquid collection chamber 12. Image 6 , 7 It is the injection panel 2 with two injection holes 21, and the injection holes are arranged symmetrically at a certain angle with the axis of the injection panel 2. There are two injection hole inlets 22 on the other side of the injection panel. Figure 8 It is a resonant cavity housing 4, on which a resonant cavity 41 and a resonant cavity entrance 42 are provided. The liquid collection chamber housing 1 and the injection panel 2 are connected by bolts in a flange manner. The liquid collection chamber housing 1 and...

Embodiment 2

[0027] Embodiment two: A self-excited oscillating jet impinging nozzle for the atomization of complex fluids, the second embodiment is as Picture 10 , 11 As shown in Figure 12, the main difference between the second embodiment and the first embodiment is that three nozzle holes 21 are evenly arranged at the bottom of the injection panel 2, and correspondingly, there are three injection hole inlets 22 on the upper part of the injection panel. In this way, three self-oscillating jets impinging nozzles are formed.

[0028] Another difference between the second embodiment and the first embodiment is that the nozzle hole 21 and the resonant cavity inlet 42 are both tapered channels (such as Picture 12 ). Since the shear rate of fluid flowing along the axial direction in the tapered channel is increased, it has a thinning effect on complex fluids with shear thinning properties. Both the nozzle hole 21 and the resonant cavity inlet 42 are designed in the form of a tapered channel, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com