Foaming milk with excellent foaming effect and preparation method thereof

A foaming effect and milk technology, which is applied in the fields of milk preparations, dairy products, and applications, can solve problems such as poor foaming effect, and achieve the effect of smooth taste, good stability and rich milk fragrance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Product formula (calculated per ton of final product):

[0026] raw material

Raw material requirements

Amount added

milk

F ≥ 3.1%, P ≥ 2.9%, SNF ≥ 8.1%

993kg

P≥85%, lactose≤5.0%

4.0kg

3.0kg

[0027] The preparation method comprises the following steps:

[0028] 1) According to the recipe, use a water-powder mixer to disperse microcrystalline cellulose into milk at 40°C, and the amount of milk is 500kg;

[0029] 2) The microcrystalline cellulose milk solution obtained in step 1) was mixed and homogenized: the homogenization temperature was 65° C., and the first-level homogenization was performed at 200 bar;

[0030] 3) According to the recipe, mix the remaining milk with the microcrystalline cellulose milk solution obtained in step 2), then add milk protein and continue stirring for 20 minutes;

[0031] 4) Homogenize the liquid obtained in step 3), the homogeniz...

Embodiment 2

[0038] Product formula (calculated per ton of final product):

[0039] raw material

[0040] Its preparation method comprises the following steps:

[0041] 1) According to the recipe, disperse microcrystalline cellulose and milk protein into milk at 50°C and stir for 20 minutes;

[0042] 2) Homogenize the liquid obtained in step 1), the homogenization temperature is 75°C, and the pressure is successively 30bar and 150bar for secondary homogenization;

[0043] 3) Sterilize the homogenized liquid in step 2), the sterilization condition is 120°C, and the sterilization time is 15 seconds;

[0044] 4) cooling the liquid obtained after the sterilization in step 3) to 5-10°C;

[0045] 5) Filling the liquid after standing in step 4) to obtain the foamed milk of the present invention.

[0046] test result

[0047] project

[0048] Fat

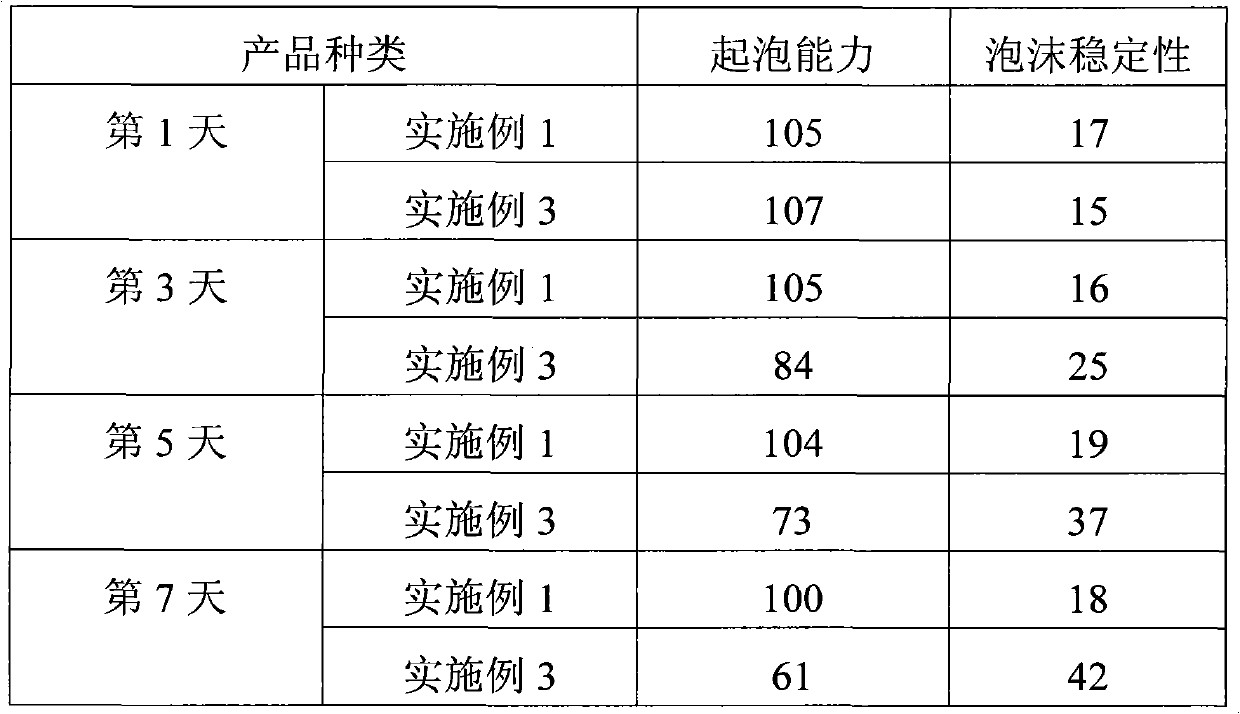

Embodiment 3

[0050] Product formula (calculated per ton of final product):

[0051] raw material

[0052] The preparation method comprises the following steps:

[0053] 1) According to the recipe, use a water-powder mixer to disperse microcrystalline cellulose into milk at 40°C, and the amount of milk is 500kg;

[0054] 2) The microcrystalline cellulose milk solution obtained in step 1) was mixed and homogenized: the homogenization temperature was 65° C., and the first-level homogenization was performed at 200 bar;

[0055] 3) According to the recipe, mix the remaining milk with the microcrystalline cellulose milk solution obtained in step 2), then add milk protein and continue stirring for 20 minutes;

[0056] 4) Homogenize the liquid obtained in step 3), the homogenization temperature is 65° C., and perform a first-level homogenization at 200 bar;

[0057] 5) Sterilize the homogenized liquid in step 4), the sterilization condition is 85°C, and the sterilization time is 15 sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com