Method for preparing cathode electrode material of nanobelt-type lithium ion battery

A lithium-ion battery, cathode electrode technology, applied in the direction of battery electrodes, nanotechnology, circuits, etc., can solve the problems of research and practical application limitations, poor battery cycle performance, non-reversible process, etc., achieve no by-products, reduce interface resistance , the effect of inhibiting expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Measure 200 mL of HY1001M hydrogen ion exchange resin (produced by Beijing Haideneng Chemical Company). First fill the exchanger with water from the bottom to 1 / 2, and then slowly fill the resin from the upper port to ensure that there are no air bubbles. After the resin is fully loaded into the exchanger, first soak it with about 10wt% NaCl solution for 8 hours, and then backwash the resin layer with deionized water until the effluent is basically clear without obvious odor, impurities or finely divided resin. Then use about 2 times the volume of the resin, that is, about 400mL of HCI solution with a volume ratio of 5% concentration, at about 3cmmin -1 Flow rate through the resin layer. After the HCl solution has completely flowed through the exchanger, soak the resin with newly prepared HCl with a concentration of 5% by volume for about 4 hours. Drain the acid solution, rinse the resin with deionized water until the effluent is basically neutral. Then use 400mL of ...

Embodiment 2

[0026] The ion exchange resin column was treated as Example 1 to obtain a clear green colloid. Transfer the obtained colloid to a hydrothermal kettle with a polytetrafluoroethylene liner, seal the lid of the kettle tightly, and react in an oven at 180°C for 14 hours, take out the reaction kettle and let it cool naturally in the air, filter and wash the precipitate, and remove it under vacuum at 80°C. Dry for 8 hours to get MoO 3 nanobelt.

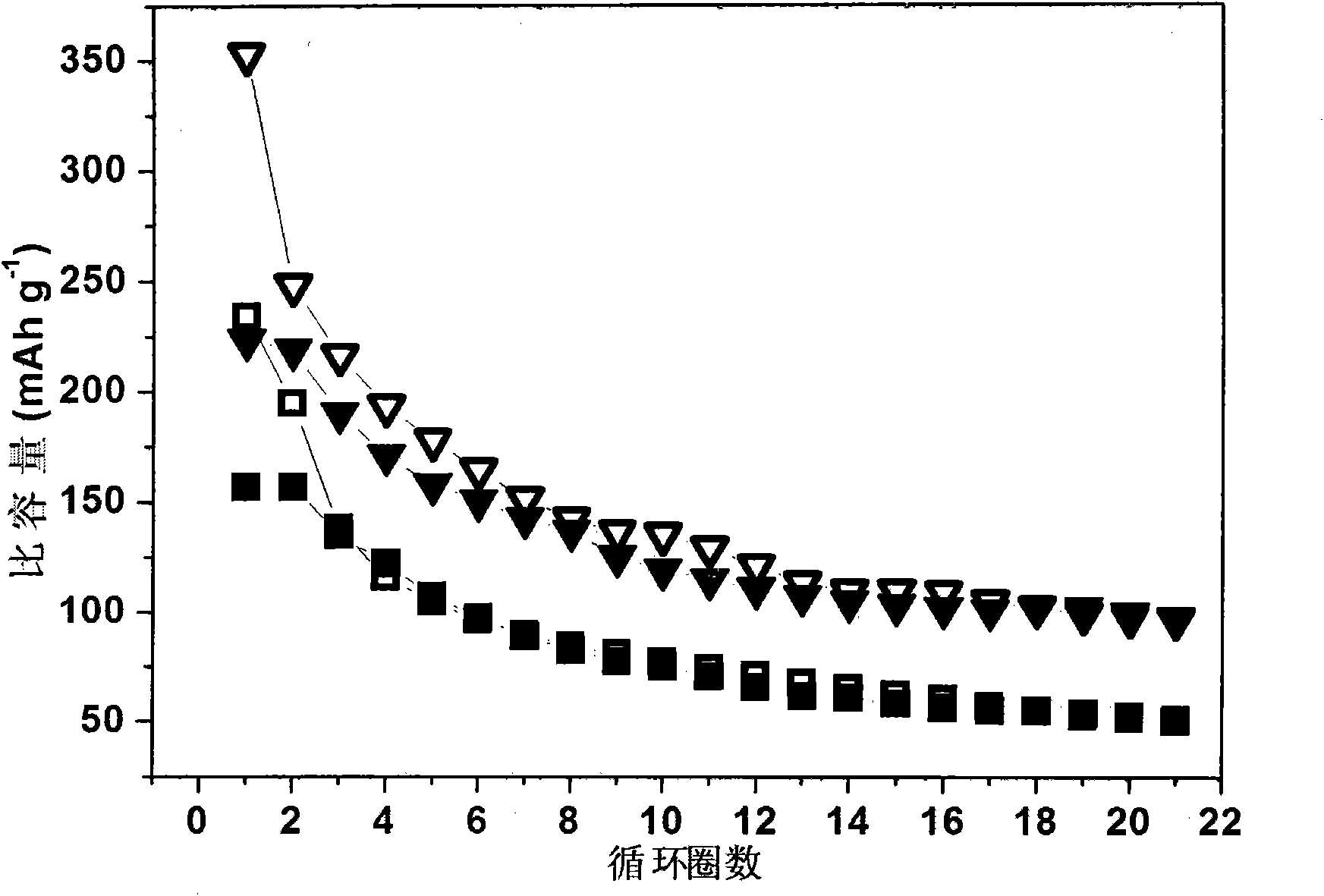

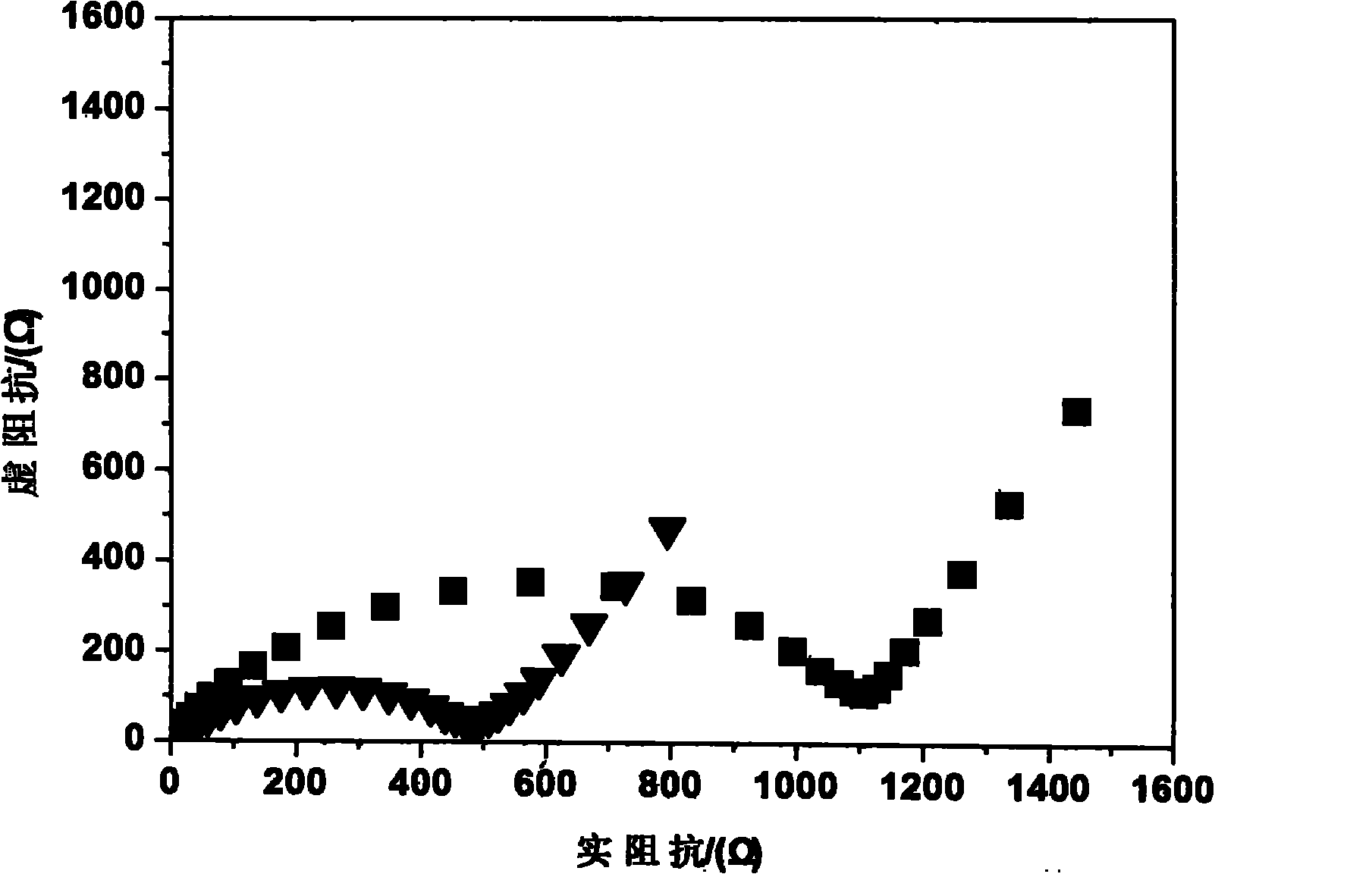

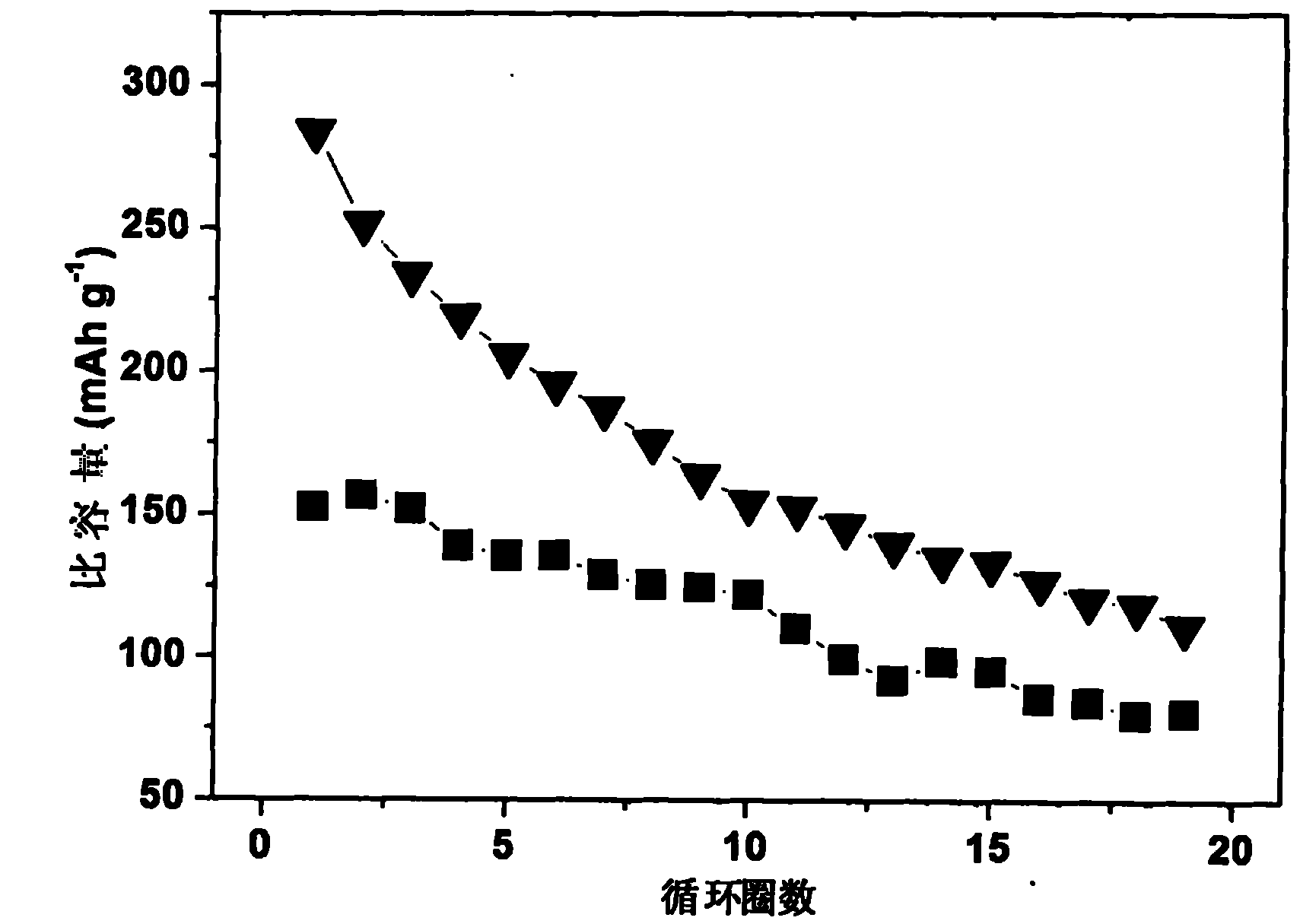

[0027] Weigh 0.2g of the prepared MoO 3 nanobelts with 0.661 g of anhydrous MgCl 2 , dissolved in 30mL deionized water, ultrasonically dispersed for 0.5 hours, stirred for two days, then transferred the resulting solution to a 45mL polytetrafluoroethylene liner hydrothermal kettle, sealed the lid tightly, and reacted in an oven at 180°C for 16 hour, take out the reaction kettle to cool naturally in the air, select 0.2μm polytetrafluoromembrane, filter through suction, wash the precipitate repeatedly with deionized water until the pH valu...

Embodiment 3

[0030] The ion exchange resin column was treated as Example 1 to obtain a clear green colloid. Transfer the obtained colloid to a hydrothermal kettle with a polytetrafluoroethylene liner, seal the lid of the kettle tightly, and react in an oven at 180°C for 45 hours, take out the reaction kettle and let it cool naturally in the air, filter and wash the precipitate, and remove it under vacuum at 80°C Dry for 8 hours to get MoO 3 nanobelt.

[0031] Weigh 0.2g of the prepared MoO 3 nanoribbons with 1.32 g anhydrous MgCl 2 , dissolved in 30mL deionized water, ultrasonically dispersed for 0.5 hours, stirred for five days, then transferred the resulting solution to a 45mL polytetrafluoroethylene-lined hydrothermal kettle, sealed the lid tightly, and reacted in an oven at 180°C for 20 hour, take out the reaction kettle to cool naturally in the air, select 0.2μm polytetrafluoromembrane, filter through suction, wash the precipitate repeatedly with deionized water until the pH value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com