Air-cooling device for electrodeless lamp

An air-cooling device and electrodeless lamp technology, which is applied to the parts and components of gas discharge lamps, can solve the problems of power drop, high failure of electrodeless lamps, and inability to transmit temperature, and achieves production and manufacturing specifications, and has a perfect, reliable and convenient structure. The effect of installation

Inactive Publication Date: 2011-04-13

ZHEJIANG COUSON ELECTRONICS TECH +2

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The magnetic core material loses its function due to high temperature, the temperature in the bubble cannot be transmitted, the coil insulation layer on the coupler melts, the high-temperature insulation material in the coupler rapidly ages, and the heat conduction rod cannot dissipate heat quickly

As a result, the power dropped significantly, and under the high-voltage impact of multiple ignitions in an instant, the outer insulating layer of the coil was finally broken down, causing the entire electrodeless lamp to be damaged.

Such electrodeless lamps are actually used in fully sealed street lamps and floodlights. The faults of electrodeless lamps are high and the technical indicators are low, so they cannot be effectively popularized and applied on a large scale.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

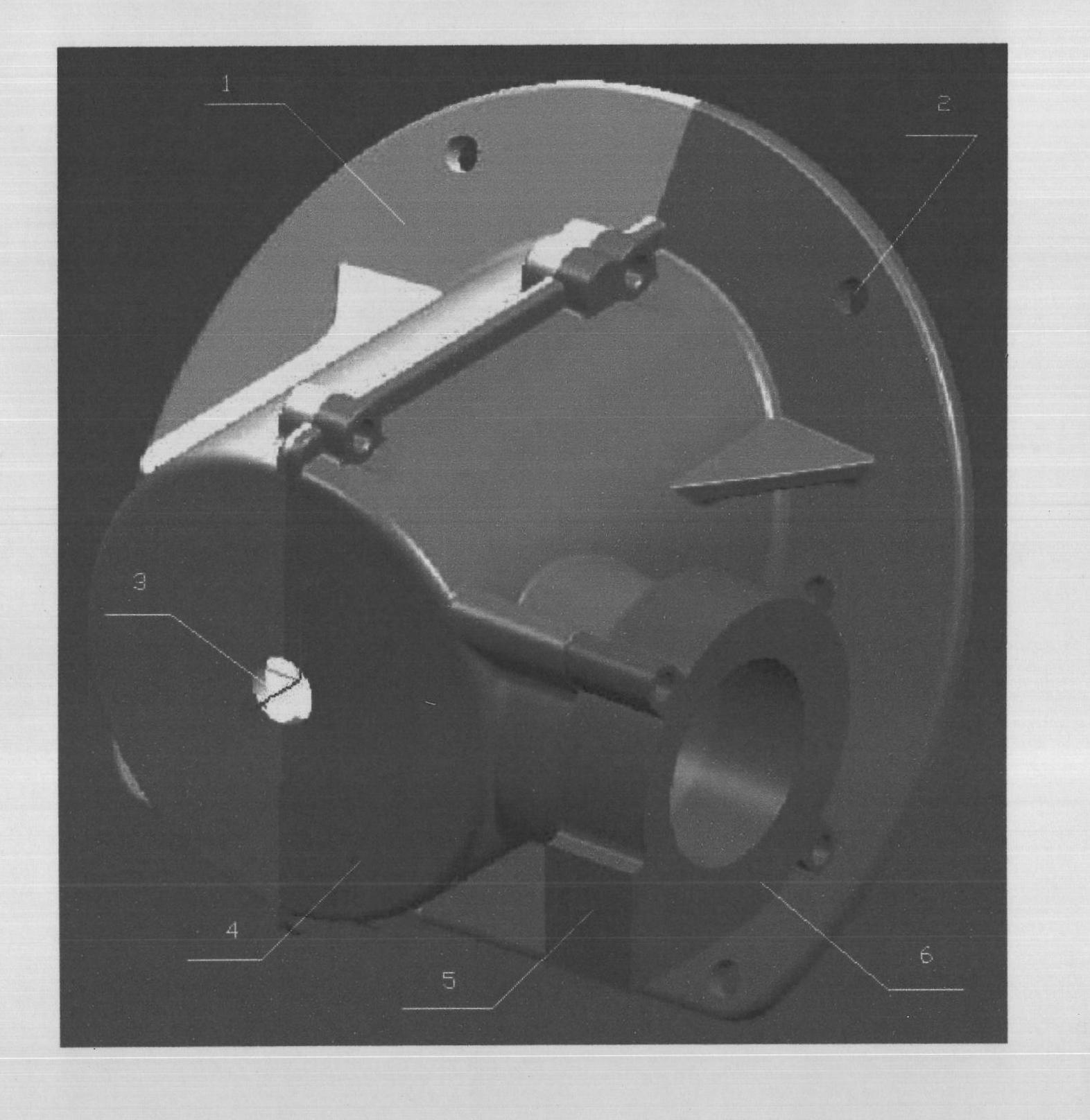

[0010] exist figure 1 Among them, the cast aluminum seat is fastened with the coupler (1), and connected with the reflector (2), the wire is led out (3) the cold air alternating plate (4), the hot air outlet (5) the low-noise and low-power fan, and Ensure reliable combination of components and connection points.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides an air-cooling device for an electrodeless lamp. The air-cooling device can keep the Curie temperature inside a lamp body not higher than over 180 DEG C. The combination of the air-cooling device and the electrodeless lamp is an integrated heat dissipation structure; a high-temperature resistant fan is a part for dissipating heat in the lamp body; accumulated heat generated in the lamp body is directly dissipated outside the lamp body after the high-temperature resistant fan is started; and the heat is dissipated by directly connecting an aluminum component structure of a heat dissipation combination with a coupler.

Description

Technical field [0001] The invention relates to an air-cooled device for an electrodeless lamp, in particular to a device that can completely solve power instability caused by temperature rise in the bubble body and component damage caused by high temperature. Background technique [0002] At present, the temperature in the applied high-power electrodeless bulb climbs to more than 250 degrees. The magnetic core material loses its function due to high temperature, the temperature in the bubble cannot be transmitted, the coil insulation layer on the coupler melts, the high-temperature insulation material in the coupler rapidly ages, and the heat conduction rod cannot dissipate heat quickly. As a result, the power dropped significantly, and under the high-voltage impact of multiple ignitions in an instant, the outer insulating layer of the coil was finally broken down, causing the entire electrodeless lamp to be damaged. Such electrodeless lamps are actually used in fully seal...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01J61/52

Inventor 施隆龙黄澄敏

Owner ZHEJIANG COUSON ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com