Distributed optical fiber and flow pressure value-based pipeline leakage joint detection method

A distributed optical fiber, flow pressure technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problems of unstable pipeline flow, complicated cabin background noise, and short ship pipeline distance. Achieving the effect of solving the problem of reciprocity, significant economy and strong complementarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

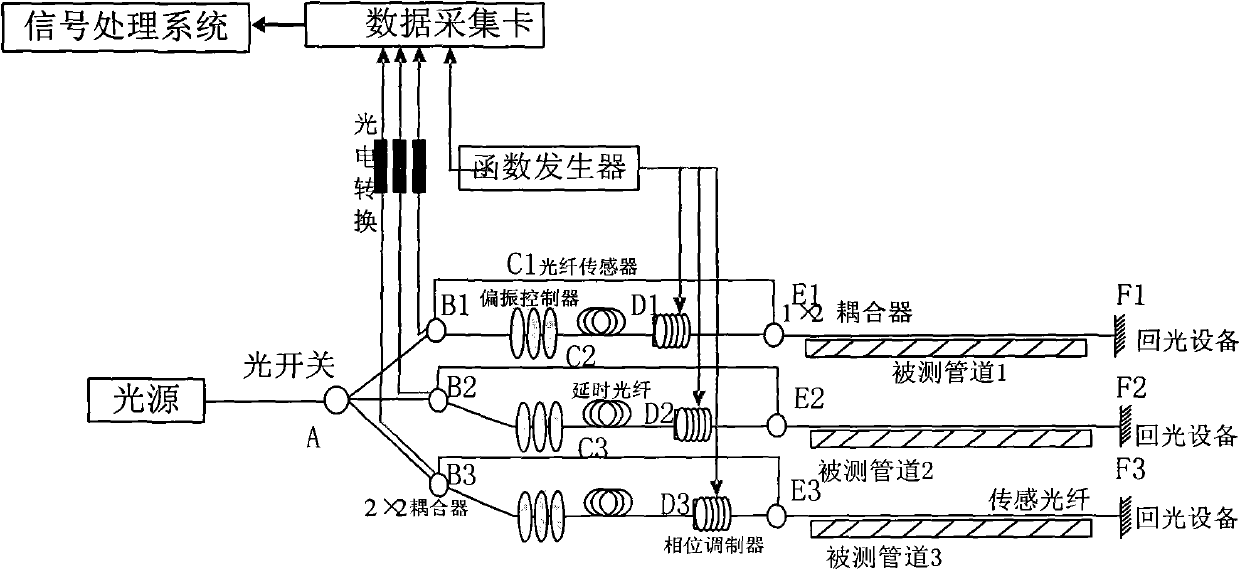

[0021] The specific implementation manner of the present invention will be described below in conjunction with the technical scheme and accompanying drawings. The embodiment of the improved distributed optical fiber pipeline leak detection method based on Sagnac interferometer principle used in the present invention, as attached figure 1 shown.

[0022] Principle of the present invention is:

[0023] The distributed optical fiber sensing method is a distributed optical fiber pipeline leak detection method based on the Sagnac interferometer principle. The pipeline leakage detection principle of this method is: the optical fiber sensor is arranged along the pipeline. When a leakage occurs somewhere in the pipeline, the leakage fluid will rub against the wall of the leakage hole, and a stress wave (that is, the leakage acoustic emission signal) will be excited on the pipeline wall. ), when the optical fiber is attached to the tube wall, the stress wave acts on the optical fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com